Gapping wall solid coating for old wall renovation, and preparation method thereof

An old wall and coating technology, applied in the field of old wall renovation and brushed wall solid coating and its preparation, can solve problems such as the inability to strengthen the adhesion between the old wall and the new coating, the wall falling off, etc., and achieve excellent stability Good performance and workability, easy operation, good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The second aspect of the embodiment of the present application provides a method for preparing an old wall renovation brushed wall solid coating, comprising the following steps:

[0074] S01. Provide various raw materials according to the old wall renovation brushed wall solid paint;

[0075] S02. Perform the first mixing treatment on the water reducer, cellulose and water to obtain the first mixed material;

[0076] S03. Perform a second mixing treatment on the emulsion and the hydrophobic agent to obtain a second mixed material;

[0077] S04. Performing a third mixing treatment on the first mixed material, the second mixed material and the auxiliary agent to obtain the first component;

[0078] S05. Quartz sand and cement are subjected to the fourth mixing treatment to obtain the second component;

[0079] S06. The first component and the second component are mixed in proportion to obtain the old wall renovation brushed wall solid paint.

[0080] The preparation me...

Embodiment 1

[0095] Old wall renovation brushed wall solid coating and preparation method thereof

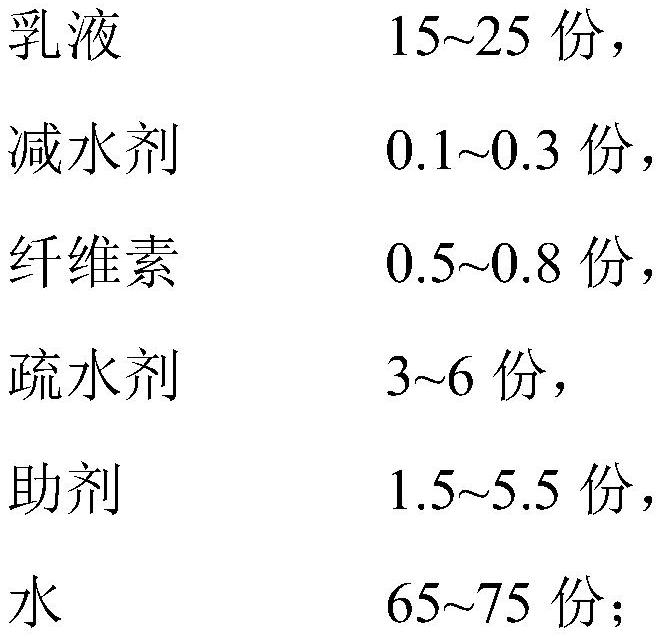

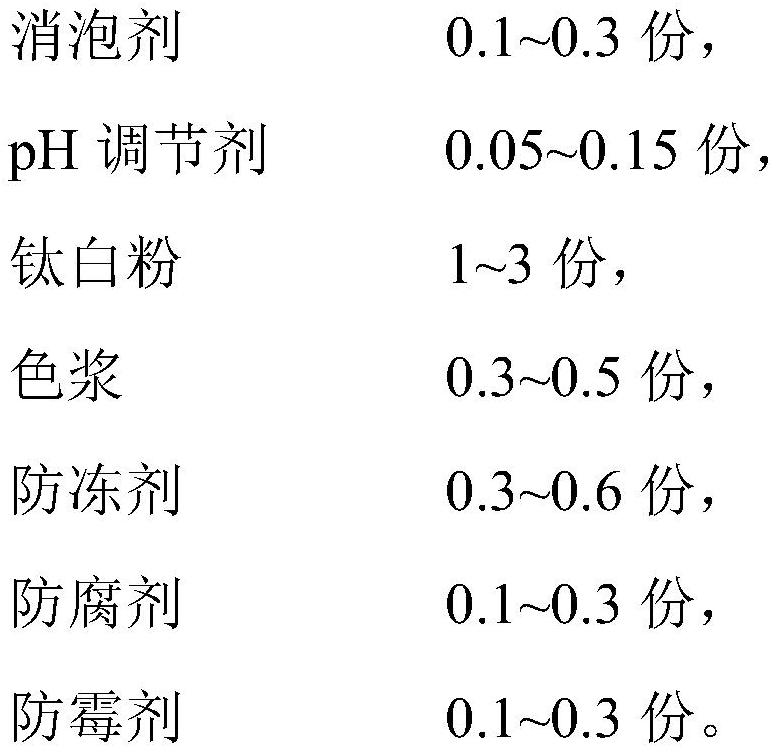

[0096] Old wall renovation brushed wall solid paint

[0097] The old wall refurbishment brushed wall solid paint is composed of the components shown in the following table 1:

[0098] Table 1

[0099]

[0100]

[0101] Preparation method of roughened wall-fixed coating for renovation of old walls

[0102] Table 1 according to embodiment 1 provides each raw material of old wall refurbishment brushed wall solid paint;

[0103] (1) Add water to the reaction vessel, and put in water reducer, cellulose and defoamer in sequence at a speed of 400rpm, and disperse for 5 minutes;

[0104] (2) Adjust the rotating speed to 900rpm, put in pH regulator, titanium dioxide, color paste and antifreeze in turn, increase the rotating speed as the viscosity increases, and disperse for 25 minutes;

[0105] (3) At a rotating speed of 600rpm, add emulsion, hydrophobic agent, preservative and antifunga...

Embodiment 2

[0109] Old wall renovation brushed wall solid coating and preparation method thereof

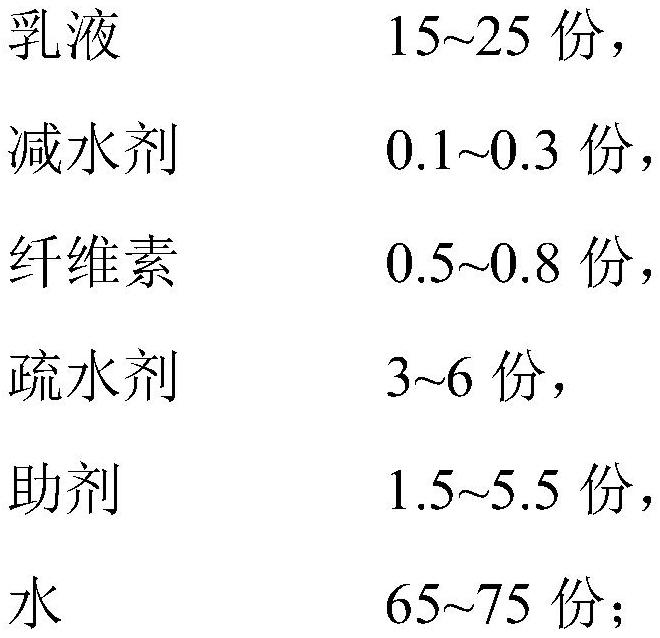

[0110] Old wall renovation brushed wall solid paint

[0111] The old wall refurbishment brushed wall solid paint is composed of the components shown in the following table 2:

[0112] Table 2

[0113]

[0114] Preparation method of roughened wall-fixed coating for renovation of old walls

[0115] Table 2 according to embodiment 2 provides each raw material of old wall refurbishment brushed wall solid coating;

[0116] (1) Add water to the reaction vessel, put in water reducer, cellulose and defoamer in sequence at a speed of 500rpm, and disperse for 6 minutes;

[0117] (2) Adjust the rotating speed to 1000rpm, put in pH regulator, titanium dioxide, color paste and antifreeze in turn, increase the rotating speed as the viscosity increases, and disperse for 20 minutes;

[0118] (3) At a rotational speed of 700rpm, add emulsion, hydrophobic agent, preservative and antifungal agent in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap