Wear-resistant home appliance color-coated steel plate and preparation method thereof

A color-coated steel plate, anti-wear technology, applied in the field of steel plate manufacturing, can solve problems such as limited wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

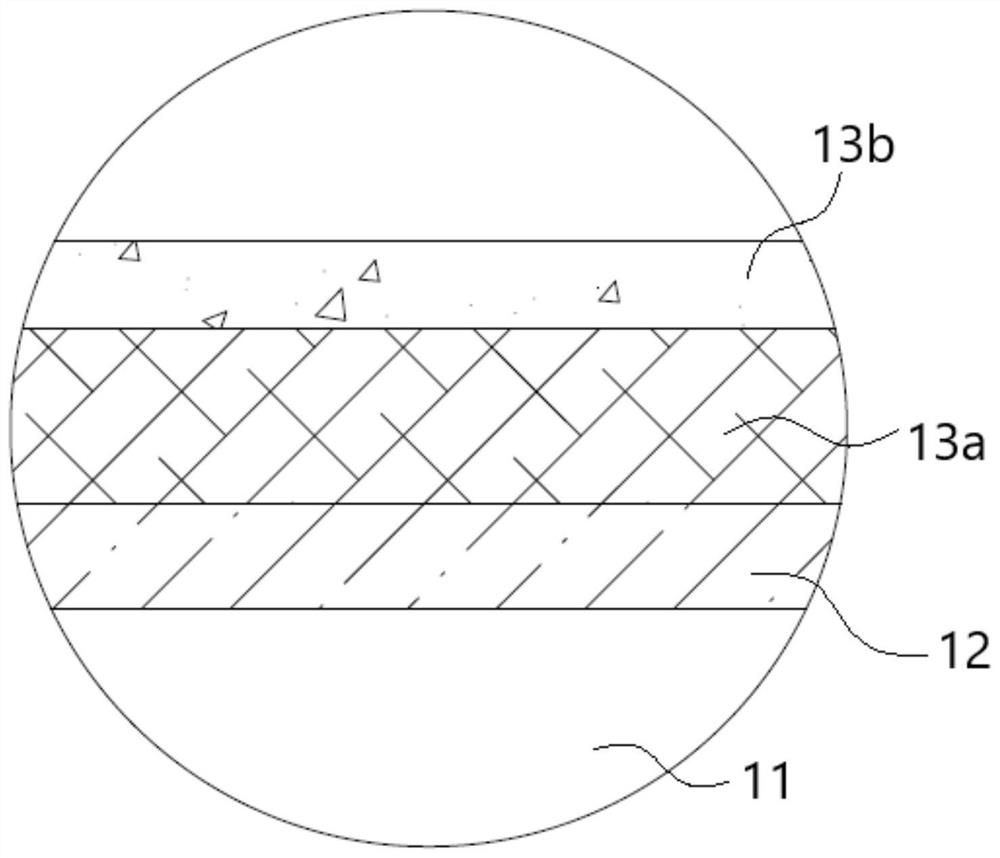

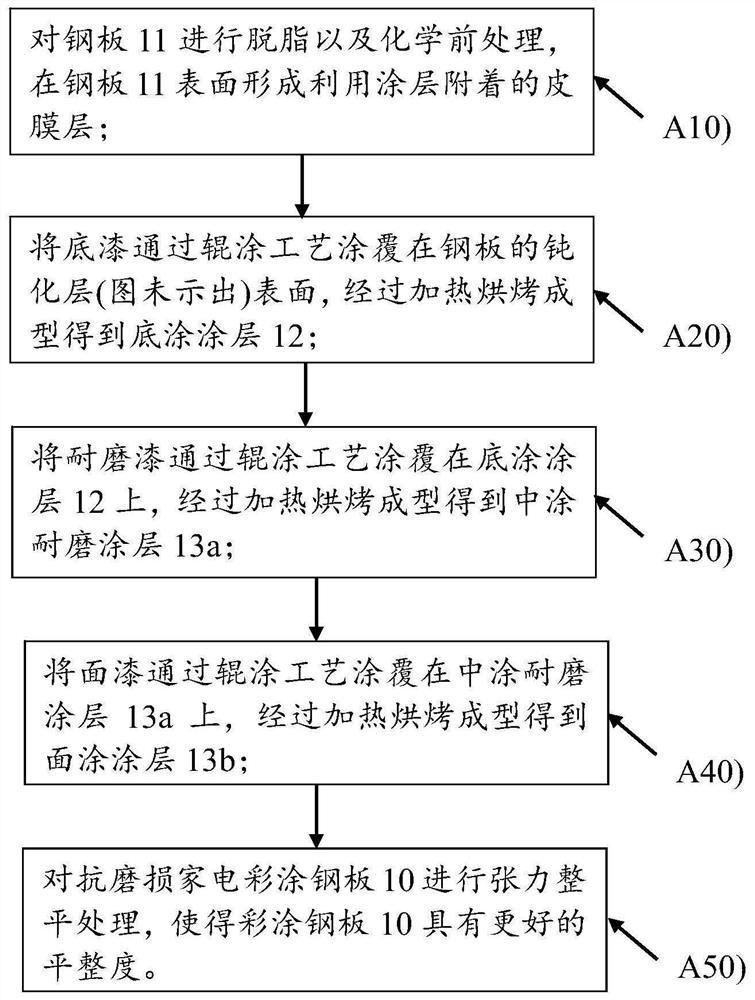

[0030] Preferably, see further image 3 As shown, a method for preparing the above-mentioned anti-wear home appliance color-coated steel plate 10 includes the following steps:

[0031] A10), the steel plate 11 is degreased and chemically pretreated, and a film layer attached by a coating is formed on the surface of the steel plate 11, and the film layer adopts phosphate or phosphate composite oxide;

[0032] A20), the primer is coated on the surface of the passivation layer (not shown) of the steel plate by a roll coating process, and the primer coating 12 is obtained through heating and baking forming;

[0033] A30), the wear-resistant paint is coated on the primer coating 12 by a roll coating process, and the middle coating wear-resistant coating 13a is obtained through heating and baking forming;

[0034]A40), the top coat is coated on the middle coating wear-resistant coating 13a by a roll coating process, and the top coating 13b is obtained through heating and baking for...

Embodiment 1

[0039] Embodiment 1: the remaining technical schemes of this embodiment 1 are the same as the above implementation technical schemes, wherein the wear-resistant paint includes 35wt% epoxy resin, 20wt% first saturated carboxyl group modified by nano-silica powder wear-resisting Polyester resin (acid value 40-45mgKOH / g), 25wt% of the second saturated carboxyl polyester resin (acid value 65-72mgKOH / g) through nano-silica powder wear-resisting modification, 3wt% Isocyanate and 17 wt% solvent.

Embodiment 2

[0040] Embodiment 2: all the other technical solutions of this embodiment 2 are the same as the above implementation technical solutions, wherein the wear-resistant paint comprises 35wt% epoxy resin, 20wt% the first saturated carboxyl group modified by nano-silica powder wear-resisting Polyester resin (acid value 40-45mgKOH / g), 15wt% of the second saturated carboxyl polyester resin (acid value 65-72mgKOH / g) through nano-silica powder wear-resisting modification, 3wt% Isocyanate, 2wt% glass powder and 25wt% solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com