Concrete face rockfill dam soft foundation reinforcing structure and construction method

A technology for concrete slabs and weak foundations, applied in infrastructure engineering, geotextiles, dams, etc., can solve problems such as difficult to coordinate deformation, increase soil liquefaction, and difficulty in resisting liquefaction, so as to increase strength, reduce uneven settlement, Conducive to the effect of drainage consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

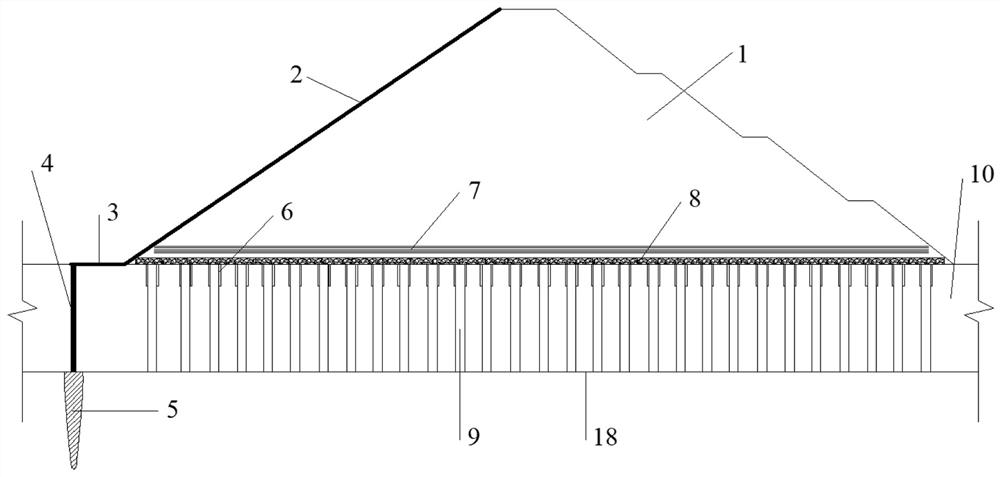

[0030] Such as Figure 1-4 , a weak foundation reinforcement structure for a concrete face rockfill dam, which includes a geogrid reinforced cushion 7, a geocell reinforced cushion 8 and a gravel pile 9 arranged inside the dam body; the gravel pile 9 Composite geotextile 6 is wrapped and fixed at the top of the top, and the gravel pile 9 extends into the weak foundation 10; the top layer of the weak foundation 10 is the dam body filler 1; the surface layer of the dam body filler 1 is provided with a concrete panel 2, The bottom end of the concrete panel 2 is connected to the concrete connecting plate 3, and the bottom of the end of the concrete connecting plate 3 is provided with a concrete cut-off wall 4, and the concrete cut-off wall 4 extends into the weak foundation 10, and the concrete cut-off wall 4 extends into the weak foundation 10. The bottom of the seepage wall 4 is provided with an anti-seepage curtain 5 . By adopting the above-mentioned foundation reinforcement s...

Embodiment 2

[0040] The invention discloses a construction method for strengthening the weak foundation of a concrete face rockfill dam, which comprises the following steps:

[0041] Step 1: During construction, the concrete anti-seepage wall 4, the anti-seepage curtain 5 and the gravel pile 9 are constructed at the same time, and the gravel pile 9 is constructed sequentially according to the principle of sequentially densifying from both sides to the middle, and the pile is formed by rotating holes hole, the bottom of the gravel pile 9 is in contact with the foundation-covering interface 18, and a composite geotextile 6 matching the diameter of the pile hole is made in advance;

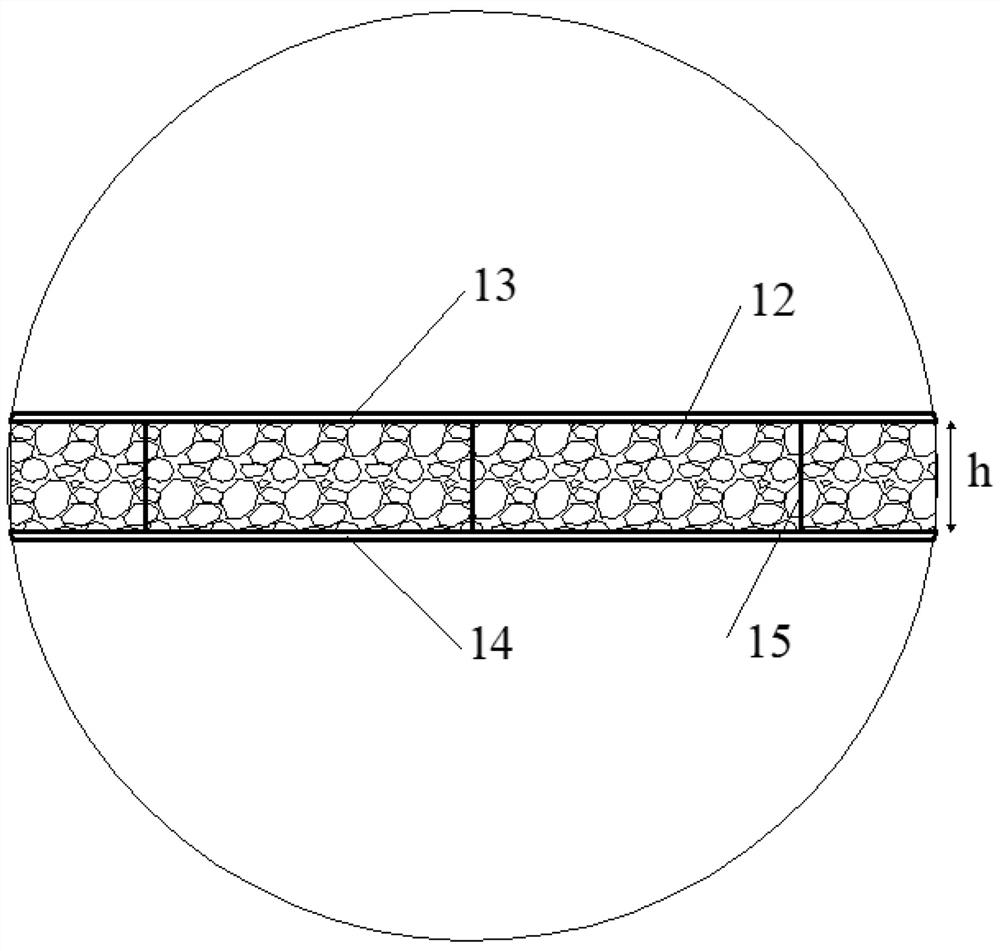

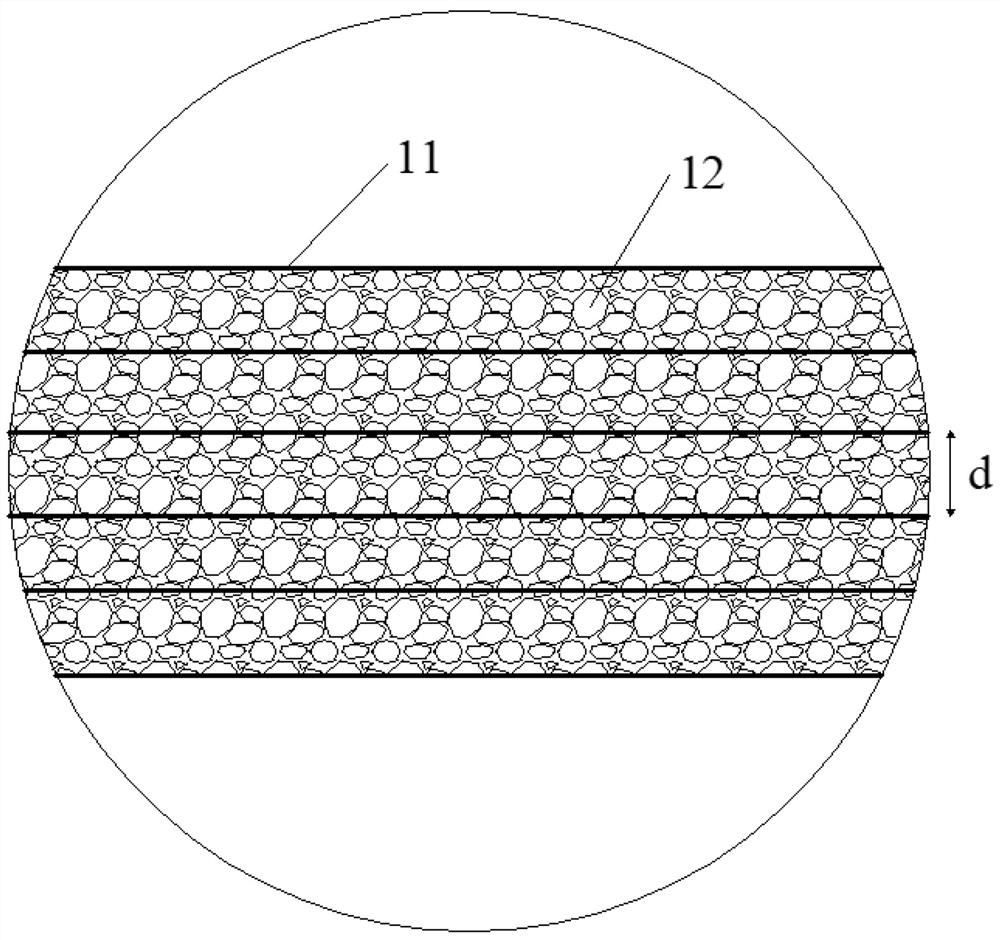

[0042] Step 2: Place the composite geotextile 6 in the pile hole, then fill in gravel and carry out impact compaction to form a gravel pile 9, lay a composite geotextile layer 14 on the surface of the foundation forming the gravel pile, and then lay a geocell 15, and fill gravel filler 12, lay composite geomembra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com