Sludge plate frame dewatering and drying composite device capable of automatic sludge falling and automatic cleaning of filter cloth and dewatering and drying method

A compound device and automatic cleaning technology, which is applied to chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as heavy workload, large land occupation, large investment, and complex system composition, and achieve The effect of reducing moisture content, protecting service life, and promoting gasification and evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The following example 1 will further illustrate the operation mode of a sludge plate and frame dehydration and drying compound device with automatic filter cloth automatic mud fall and automatic cleaning provided by the present invention, so that those skilled in the art can better understand the present invention.

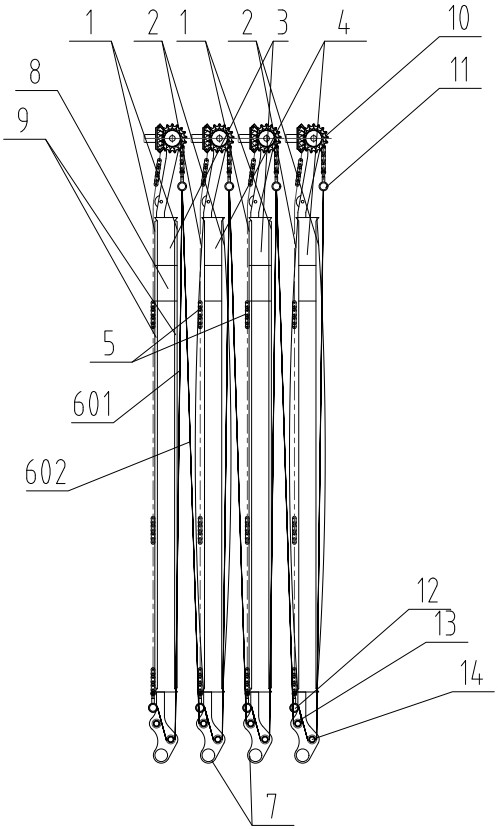

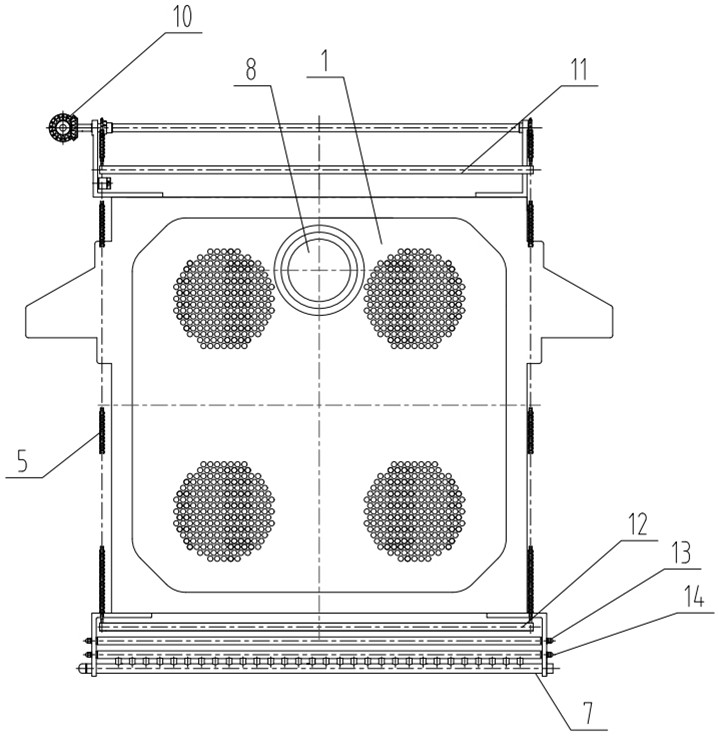

[0042] Sludge with a high water content (generally 90-99%) is pumped into the dehydrator through a high-pressure feed pump, and the sludge enters the first filter plate 3 and the second filter plate through the feed channel 8 on the filter plate In the press filter chamber formed by 4 pairs of clamps, the surface of the first filter plate 3 and the second filter plate 4 is a filter cloth structure 6, the filter cloth structure 6 retains the dry matter in the sludge, and a large amount of water in the sludge is filtered out back out. When the sludge is continuously trapped in the filter chambers of the first filter plate 3 and the second filter plate 4 by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com