A method for synthesizing bio-based polycarbonate based on isoidide and polycarbonate

A technology based on polycarbonate and isoidide, which is applied in the field of polycarbonate synthesis, can solve the difficulties of synthesizing high molecular weight polycarbonate, the difficulty of hydroxyl reactivity and effective chain growth, and the limitation of bisphenol A polycarbonate, etc. problems, to achieve the effect of ensuring the appearance and mechanical properties of the product, low biological toxicity, and increasing the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

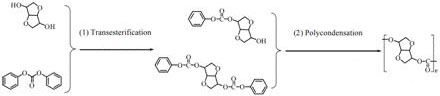

Method used

Image

Examples

Embodiment 1

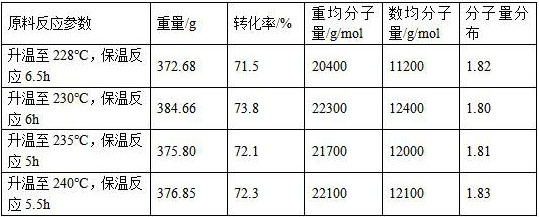

[0050] A method for synthesizing bio-based polycarbonate based on isoidide, comprising the following steps:

[0051] ①. Raw material preparation: Accurately weigh 442.5g of isoidide and 687.5g of diphenyl carbonate according to the molar ratio of isoidide and diphenyl carbonate as 1:1.06; weigh titanium according to 0.14mol% of isoidide Catalyst Ti(OCH(CH 3 ) 2 ) 4 1.21g;

[0052] ②, Reactor treatment: Use nitrogen to replace the air in the reactor three times, and use a vacuum pump to extract the gas in the reactor to ensure that the pressure of the reactor during the reaction is less than 5kPa;

[0053] ③. Mixing reaction: Put the isoidide, diphenyl carbonate and titanium-based catalyst prepared in step ① into a 1L reactor for mixing, and heat up to 228-240°C while stirring. The heating time is 4 hours, and keep warm at 230°C React for 5-6.5 hours, and obtain bio-based polycarbonate after cooling.

[0054] The bio-based polycarbonate synthesized by the above method is ...

Embodiment 2

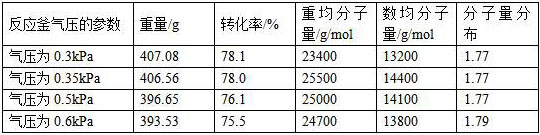

[0061] A method for synthesizing bio-based polycarbonate based on isoidide, comprising the following steps:

[0062] ①. Raw material preparation: Accurately weigh 442.5g of isoidide and 687.5g of diphenyl carbonate according to the molar ratio of isoidide and diphenyl carbonate as 1:1.06; weigh titanium according to 0.14mol% of isoidide Catalyst Ti(OCH(CH 3 ) 2 ) 4 1.21g;

[0063] ②, Reactor treatment: Use nitrogen to replace the air in the reactor for three times, and continue to provide protection. During the reaction process, use a vacuum pump to continuously extract the gas in the reactor, and control the pressure of the reactor to 0.3-0.6kPa;

[0064] ③. Mixing reaction: Put the isoidide, diphenyl carbonate and titanium-based catalyst prepared in step ① into a 1L reactor for mixing, and heat up to 228-240°C while stirring. The heating time is 4 hours, and keep warm at 230°C React for 5-6.5 hours, and obtain bio-based polycarbonate after cooling.

[0065] The bio-bas...

Embodiment 3

[0070] A method for synthesizing bio-based polycarbonate based on isoidide, comprising the following steps:

[0071] ①. Raw material preparation: Accurately weigh 442.5g of isoidide and 687.5g of diphenyl carbonate according to the molar ratio of isoidide and diphenyl carbonate as 1:1.06; weigh titanium according to 0.14mol% of isoidide Catalyst Ti(OCH(CH 3 ) 2 ) 4 1.21g, according to the mass percentage concentration of 3-10%, configure the hot phenol solution of the catalyst, and the preheating temperature is 40-60°C;

[0072]② Reactor treatment: Use nitrogen to replace the air in the reactor for three times, and continue to provide protection. During the reaction process, use a vacuum pump to continuously extract the gas in the reactor, and control the pressure of the reactor to 0.35kPa.

[0073] ③. Mixing reaction: Put the isoidide and diphenyl carbonate prepared in step ① into a 1L reactor for mixing, raise the temperature to ≥50°C, add the hot phenol solution of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com