High-flexibility polyamide natural gas pipe material and preparation method thereof

A natural gas pipe and polyamide technology, which is applied in the field of highly flexible polyamide natural gas pipe materials and their preparation, can solve problems such as corrosion of metal pipes, and achieve the effects of excellent low temperature toughness, excellent heat resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

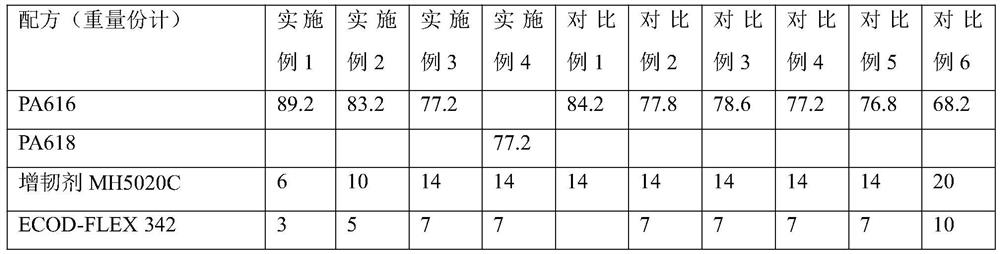

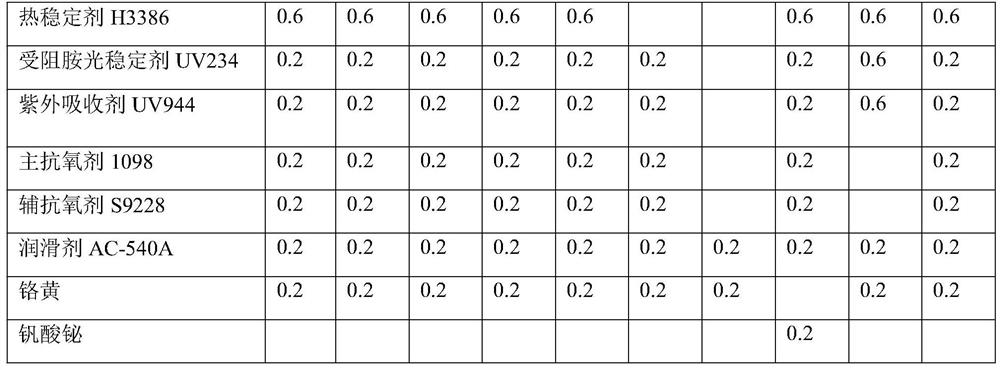

[0052] The preparation method of the highly flexible polyamide natural gas pipe material described in Embodiments 1 to 4 of the present invention comprises the following steps:

[0053] Stir and mix the toughening agent, heat stabilizer, weather resistance additives and additives evenly to obtain a mixture;

[0054] Stir and mix the dried polyamide with the plasticizer evenly, and then stir and mix with the above mixture evenly, so that the powdery additives such as additives are evenly adhered to the surface of the polyamide by means of the plasticizer. Then feed it into the twin-screw extruder through the main feeding port, and control the temperature of each section of the twin-screw extruder, from the feeding port to the exit of the head, the temperature is 180°C, 200°C, 225°C, 225°C, 230°C, 230°C , 230°C, 230°C, 230°C, 230°C, 230°C, the melt-extruded strands are cooled, dried, and then pelletized to obtain the highly flexible polyamide natural gas pipe material.

[0055]...

Embodiment 3

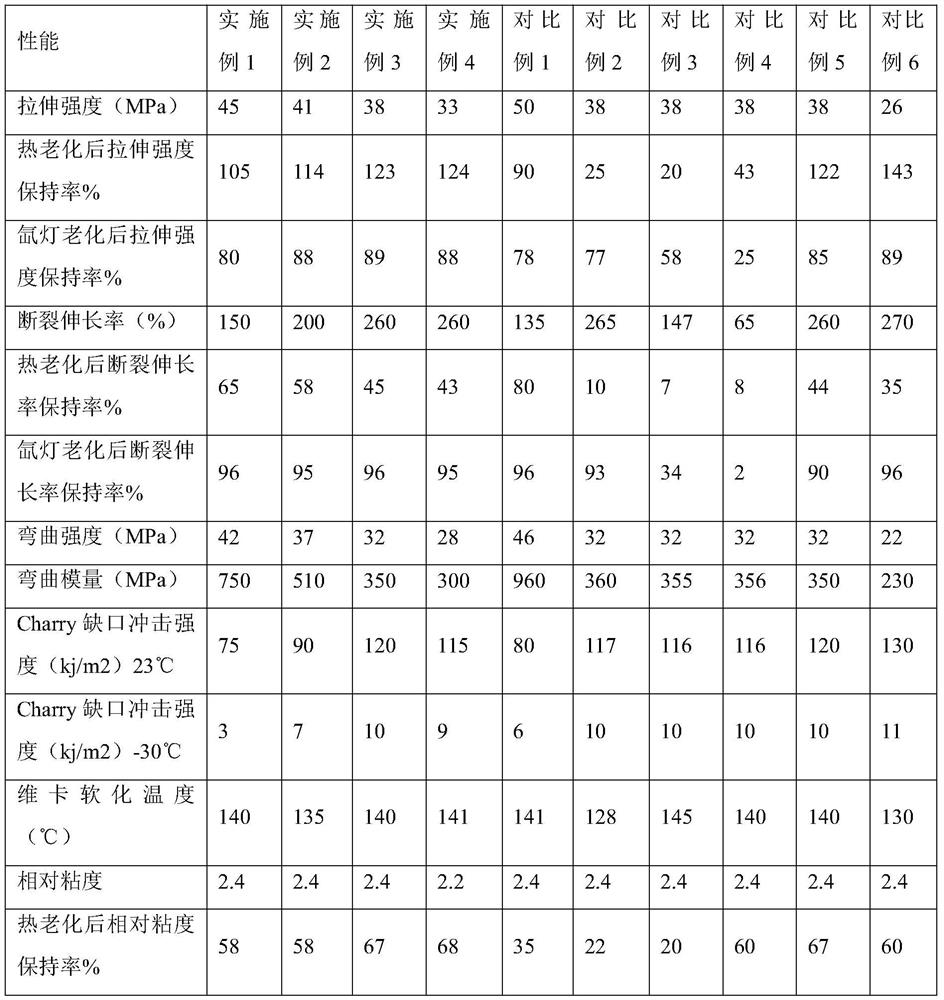

[0075] The organic copper salt heat stabilizer added in Example 3 has a larger molecular weight, better stability and higher anti-oxidation efficiency, and the material still has a very high strength retention rate under the aging condition of 130 ° C. The strength retention rate is as high as 123%, the elongation at break retention rate is also as high as 45%, and the relative viscosity is also maintained at about 67%, indicating that the organic copper salt H3386 can effectively reduce the loss of mechanical properties under high temperature aging conditions in materials, so this high Flexible natural gas pipe materials can be used for a long time at higher temperatures.

[0076] Embodiment 3 compares with comparative examples 2 and 3 and finds that comparative example 2 does not add heat stabilizers, and comparative example 3 does not add heat stabilizers and weather resistance additives. Heat and other effects make the physical and chemical properties of the material conti...

Embodiment 4

[0078] Example 4 has the same formula as Example 3, mainly because the substrate is replaced by PA616 with longer carbon chain PA618. PA618 is obtained by polycondensation of hexamethylenediamine and 18-carbon dibasic acid, but due to the relatively high reactivity of 18-carbon dibasic acid Low, and the hydrogen bond density of PA618 is lower than that of PA616, so the tensile strength and bending strength of the material are lower, but the low hydrogen bond density also makes the material more flexible and has better low temperature toughness.

[0079] Considering the performance requirements of natural gas pipe materials on strength, flexibility, and aging resistance, both Example 3 and Example 4 meet the material requirements, and Example 3 has better comprehensive performance.

[0080] The weather resistance additive of the present invention is composed of hindered phenolic antioxidant, hindered amine light stabilizer, benzotriazole ultraviolet absorber and phosphite antiox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com