Large-size cathode rare earth molten salt electrolytic bath

A molten salt electrolysis, large-scale technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high input cost, irregular electrolysis area, and large electrolyte consumption, so as to reduce the cost of masonry and increase the production capacity of a single furnace , the effect of small amount of electrolyte

Pending Publication Date: 2021-09-03

BAOTOU REWIN RARE EARTH METAL MATERIALS

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, this kind of multi-cathode electrolytic cell also has certain limitations. The more prominent problems are the high investment cost of electrolytic cell masonry, the irregular electrolysis area in the furnace, the difficulty in implementing automatic metal extraction operations, and the consumption of molten salt when the electrolytic cell is stopped and started. Large, large amount of electrolyte, inflexible production change

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] At present, the large-scale cathode rare earth molten salt electrolytic cell has been put into industrial operation. The economic indicators of the operation are as follows, the electrolytic current is 9000-12000A, the cell voltage is 8-9V, the direct power consumption is 8-9kwh / kg metal, and the material ratio is 1.1950-1.1960 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

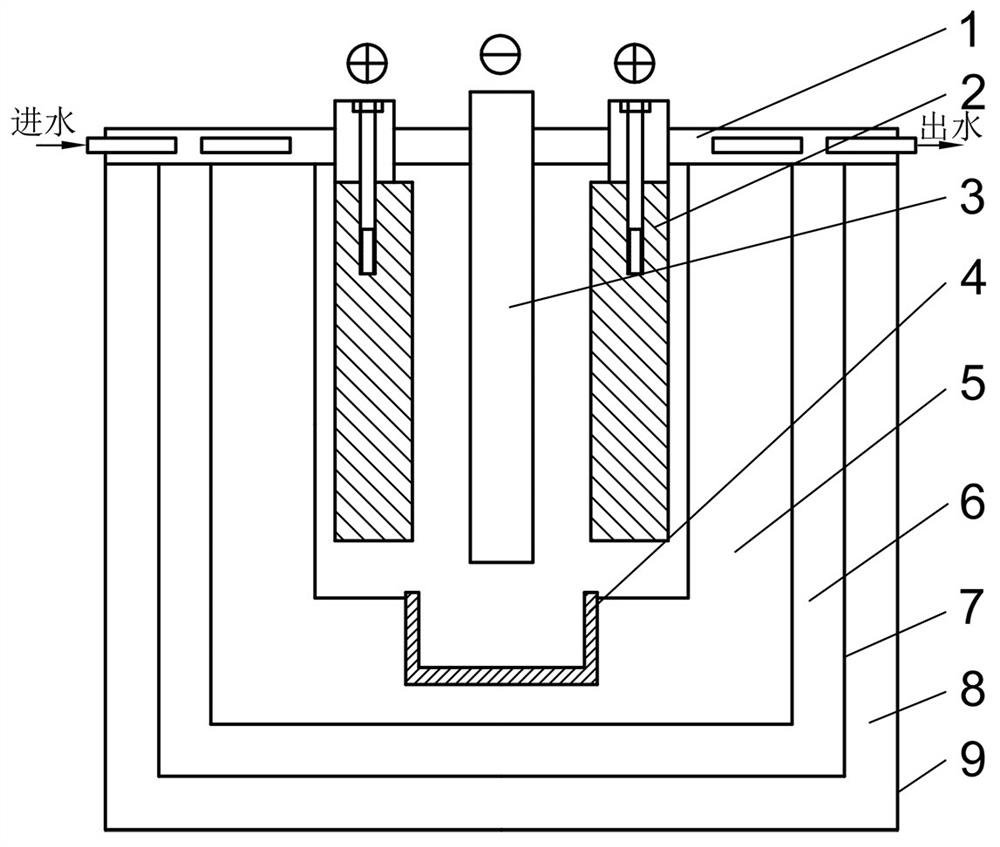

The invention relates to a large-size cathode rare earth molten salt electrolytic bath which comprises an anode current-conducting plate, an anode clamp, an anode, a cathode, a receiver, a bath body lining, a bath body leakage-proof layer, an inner protection layer, a heat preservation layer and an outer protection layer, wherein the electrolytic bath is an open single cathode and is cooled at the upper part of the electrolytic bath through a water-cooled anode current-conducting plate, so that molten salt crusts at the upper part of the bath body, and the service life of a furnace body is prolonged; a large-size tungsten cathode is manufactured through a high-temperature hot melting compression technology, and the current density of the cathode is guaranteed; and MATLAB software is used for compiling a rare earth electrolytic cell electric field numerical model to further optimize electrolytic cell process parameters, the designed electrolytic cell is high in productivity and low in power consumption, produced metal products are good in quality consistency and high in yield, the building cost of the electrolytic cell is low, an electrolytic area in a hearth is regular, the electrolytic cell is convenient to stop and start, the electrolyte dosage is small, and production switching is flexible.

Description

technical field [0001] The invention relates to the technical field of rare earth molten salt electrolysis, and specifically discloses a technical solution for a large-scale cathode rare earth molten salt electrolytic cell. Background technique [0002] The industrial production of light rare earth metals and their alloys mainly adopts the molten salt electrolysis method. The research on rare earth molten salt electrolysis technology in my country began in the 1960s, and currently the rare earth fluoride system oxide electrolysis method is mainly used. The scale of domestic electrolytic cells mainly includes 6KA-25KA grades and other specifications. Among them, the electrolytic cells below the 8KA grade all adopt circular electrolytic cells with a single cathode plugged in. The production capacity of a single furnace is low, the power consumption is high, and the quality consistency of metal products is poor. The yield is low. [0003] Baotou Ruixin Rare Earth Metal Materia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25C3/34C25C7/00

CPCC25C3/34C25C7/005

Inventor 廉华潘燚郭海涛孔向民刘雨张志军杨培绿艾玉忠孙致杰薛琪刘文晶侯磊李国栋赵越

Owner BAOTOU REWIN RARE EARTH METAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com