Utilization method of heat and materials in preparing vanadium nitrogen alloy

A vanadium nitrogen alloy and heat technology, applied in the field of iron and steel metallurgy, can solve the problems of insufficient utilization of energy resources, waste of resources, etc., and achieve the effects of reducing heating time, increasing the productivity of a single furnace, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

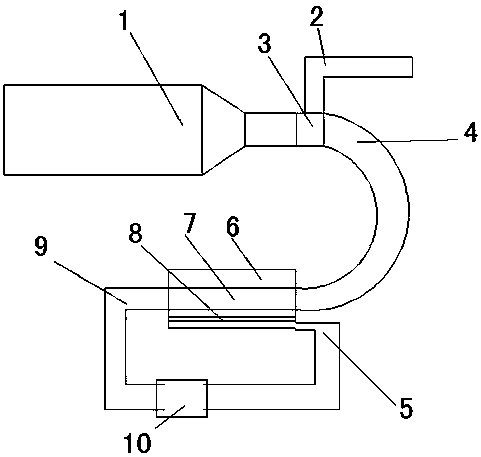

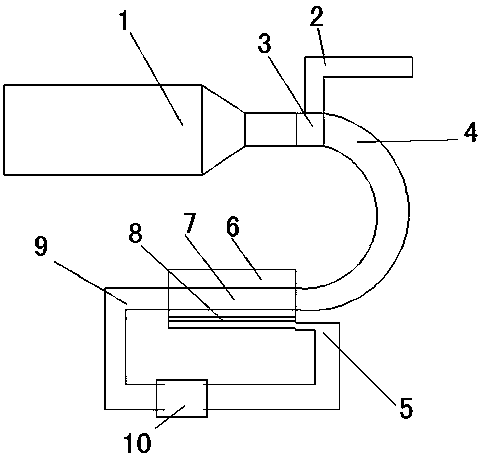

[0020] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0021] A method for utilizing heat and materials in the preparation of vanadium-nitrogen alloys, characterized in that,

[0022] Contains the following steps:

[0023] Step 1: Utilize the tail gas of the industrial intermediate frequency furnace for the production of vanadium-nitrogen alloy, recycle the heat in the tail gas, pass the discharged tail gas into the utilization furnace to make it reuse in the furnace, and use the discharged tail gas to reduce vanadium pentoxide Obtain vanadium trioxide, and at the same time use the heat of the tail gas to dry the green vanadium pentoxide pellets;

[0024] Step 2: The vanadium trioxide balls reduced by tail gas are put into the vertical kiln with intermediate frequency induction furnace at the middle end, and nitrogen gas is introduced to carry out carbonation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com