Semiconductor optical fiber coupling laser and optical fiber laser

A fiber laser and fiber coupling technology, which is applied to lasers, laser components, laser components, etc., can solve the problems of large volume, high cost, and heavy weight of high-power fiber lasers, and achieve shortened heat transfer paths, reduced weight and Small size, the effect of realizing high integration and high power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

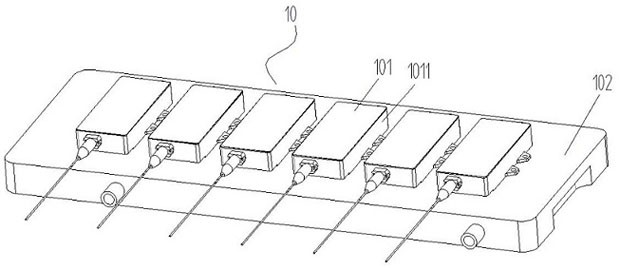

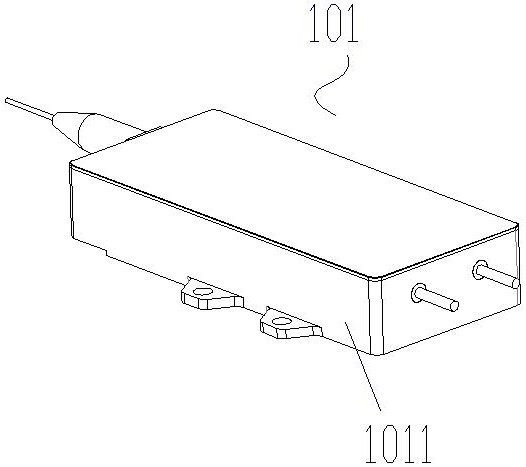

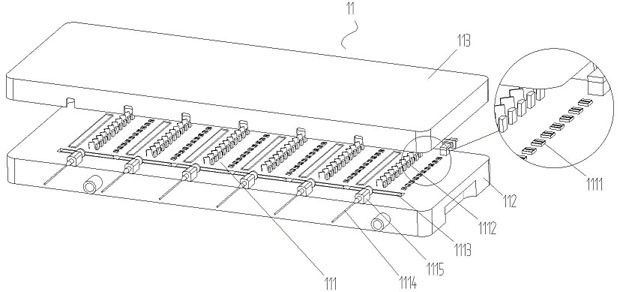

[0103] combine Figure 3 to Figure 5 As shown, this embodiment discloses a semiconductor fiber-coupled laser 11 . The semiconductor fiber coupled laser 11 includes six optical modules 111 , a cold plate 112 and a cover plate 113 . The six optical modules 111 are sequentially arranged on the upper surface of the cold plate 112 along the length direction of the cold plate 112 . The cover plate 113 adopts a thin shell structure and is connected to the cold plate 112 with the opening facing downward, and the six optical modules 111 are integrally packaged by the cover plate 113 and the cold plate 112 .

[0104] Each optical module 111 includes a COS module 1111 directly connected to the cold plate 112, an optical path array 1112, an electrode 1113, a pigtail 1114, and an optical fiber support 1115, and the COS module 1111, the optical path array 1112, The electrodes 1113, pigtails 1114 and fiber holders 1115 are the same as the COS module, optical path array, electrodes, pigtail...

Embodiment 2

[0112] combine Figure 6 to Figure 9 As shown, this embodiment discloses a semiconductor fiber-coupled laser 12 . The semiconductor fiber coupled laser 12 includes six optical modules 121 , a cold plate 122 and a cover plate 113 . The six optical modules 121 are sequentially arranged on the upper surface of the cold plate 122 along the length direction of the cold plate 122 . The cover plate 113 adopts a thin shell structure and is connected to the cold plate 122 with the opening facing downward, and the six optical modules 121 are integrally packaged by the cover plate 113 and the cold plate 122 .

[0113] Compared with Embodiment 1, the optical module 121 of this embodiment further includes a heat conducting component 1211 . Wherein, the heat conduction component 1211 is located between the COS module 1111 and the cold plate 122 as a component with high heat conduction performance, and is used for the fixed connection between the COS module 1111 and the cold plate 122 .

...

Embodiment 3

[0120] combine Figure 10 to Figure 13 As shown, this embodiment discloses a semiconductor fiber-coupled laser 13 . The semiconductor fiber coupled laser 13 includes six optical modules 131 , a cold plate 132 and a cover plate 113 . The six optical modules 131 are sequentially arranged on the upper surface of the cold plate 132 along the length direction of the cold plate 132 . The cover plate 113 adopts a thin shell structure and is connected with the cold plate 132 with the opening facing downward, and the six optical modules 131 are integrally packaged by the cover plate 113 and the cold plate 132 .

[0121] Compared with the second embodiment, the heat conducting component 1311 in the optical module 131 of this embodiment is provided with two bolt holes 13111 , and at the same time, a corresponding threaded hole 1322 is provided at the mounting groove 1321 of the cold plate 132 .

[0122] At this time, after inserting the heat conduction component 1311 into the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com