Surface acoustic wave device

A surface acoustic wave and area technology, applied to electrical components, impedance networks, etc., can solve problems such as failure to meet 5G high power requirements, filter failure, and reduced durability, and achieve improved anti-electromigration performance and increased power tolerance , Durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] (1) Embodiment one

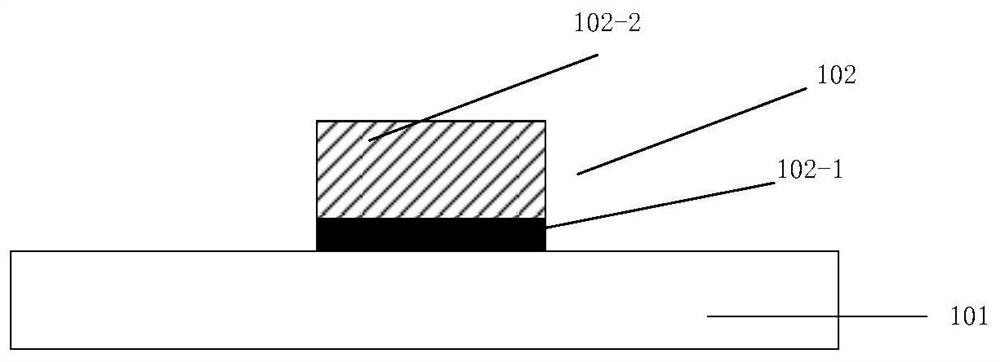

[0038] Such as figure 1 As shown, the present embodiment provides a surface acoustic wave device, including a piezoelectric substrate 101 and an IDT electrode 102. The piezoelectric substrate can be a piezoelectric substrate such as quartz (SiO2), lithium niobate (LiNbO3) or lithium tantalate (LiTaO3). crystals.

[0039] The IDT electrode 102 includes a first buffer layer 102-1 disposed on the piezoelectric substrate and a first metal layer 102-2 disposed on the first buffer layer 102-1.

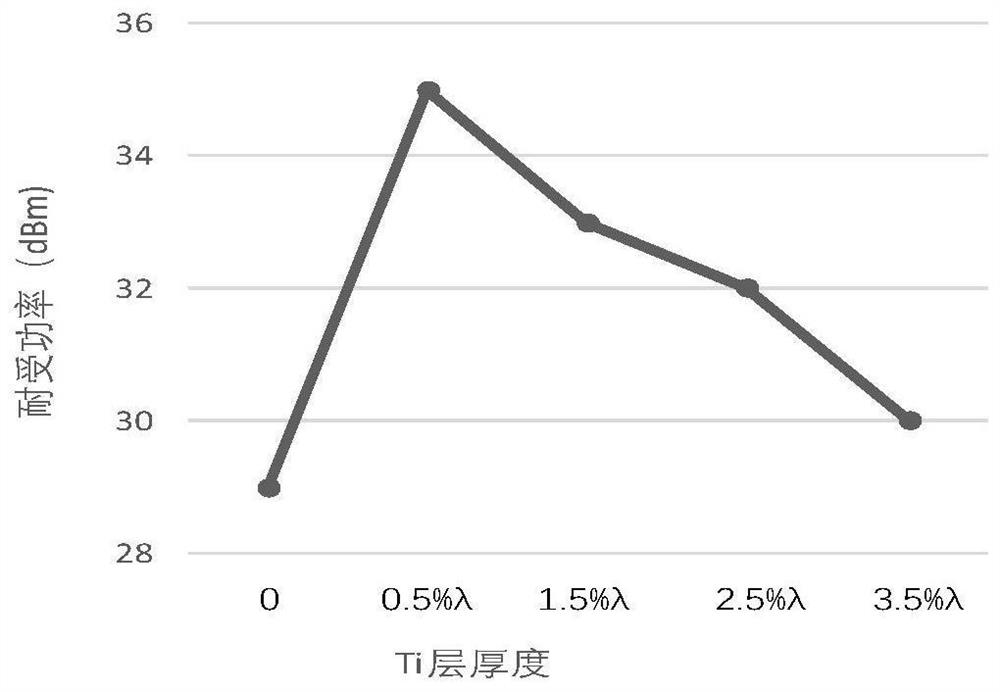

[0040] The first buffer layer 102-1 includes metal titanium, and when the wavelength of the elastic wave determined by the electrode period of the IDT electrode is λ, the thickness of the first buffer layer is 0.5% λ or less. The first metal layer 102-2 includes metal aluminum, and the thickness of the aluminum layer is in the range of 1%λ-30%λ.

[0041] Using metal titanium as the buffer layer is beneficial to form a strong Al(111) texture on the Al thin film ...

Embodiment 2

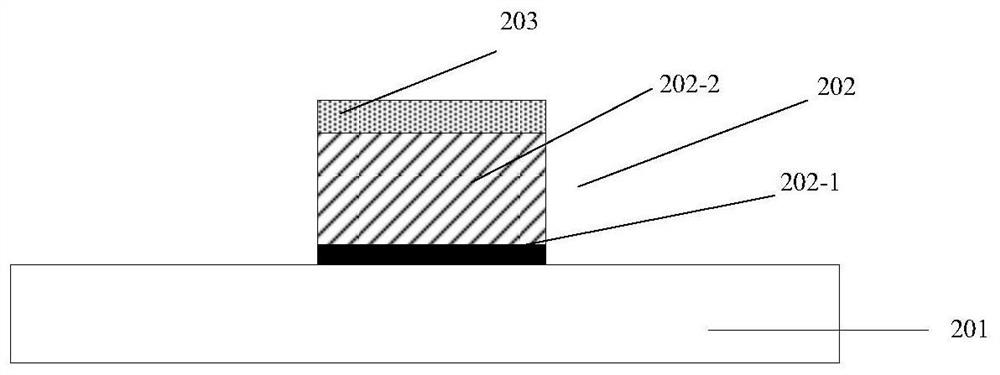

[0054] Such as image 3 As shown, this embodiment provides a surface acoustic wave device, including a piezoelectric substrate 201 and an IDT electrode 202, and the IDT electrode 202 includes a first buffer layer 202-1 disposed on the piezoelectric substrate and a first buffer layer 202-1 disposed on the first buffer layer 202. -1 on the first metal layer 202-2. A passivation layer 203 is provided on the IDT electrode 202 . The structures and components of the piezoelectric substrate 201 and the IDT electrodes 202 in this embodiment are the same as those in the first embodiment.

[0055] The passivation layer 203 includes silicon oxide, and the relationship between the thickness of the passivation layer and the thickness of each layer in the IDT electrode is determined by the following formula:

[0056] Hp=T1*Hb1+T3*Hm1+T5*Hs

[0057] Wherein, Hp is the thickness of the passivation layer, Hb1 is the thickness of the first buffer layer 202-1; T1 is the temperature compensati...

Embodiment 3

[0064] Such as Figure 4 As shown, the present embodiment provides a surface acoustic wave device, including a piezoelectric substrate 301 and an IDT electrode 302. The piezoelectric substrate can be a piezoelectric substrate such as quartz (SiO2), lithium niobate (LiNbO3) or lithium tantalate (LiTaO3). crystals.

[0065] The IDT electrode 302 in the surface acoustic wave device provided in this embodiment includes a four-layer structure, which can improve the withstand power of the surface acoustic wave device.

[0066] In this embodiment, the IDT electrode 302 includes a first buffer layer 302-1 disposed on the piezoelectric substrate, a first metal layer 302-2 disposed on the first buffer layer 302-1, and a first metal layer 302-2 disposed on the first metal layer The second buffer layer 302-1' on the second buffer layer 302-2', and the second metal layer 302-2' disposed on the second buffer layer 302-1'.

[0067] The first buffer layer 302-1 includes metal titanium, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com