Production process of antibacterial skin-friendly multi-effect wet tissue

A production process and technology for wet wipes, which are applied in the field of production technology of antibacterial, skin-friendly and multi-effect wet wipes, can solve the problem of non-woven fabric hashing, poor spray uniformity, and different wet wipe liquid content of a single piece of wet wipes. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

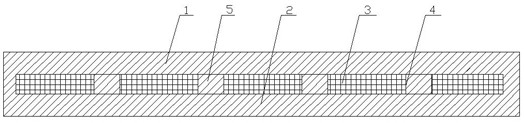

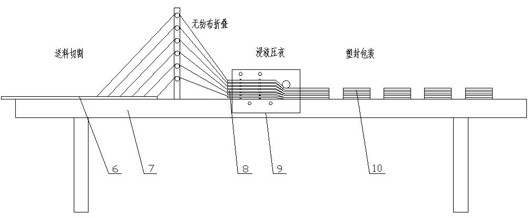

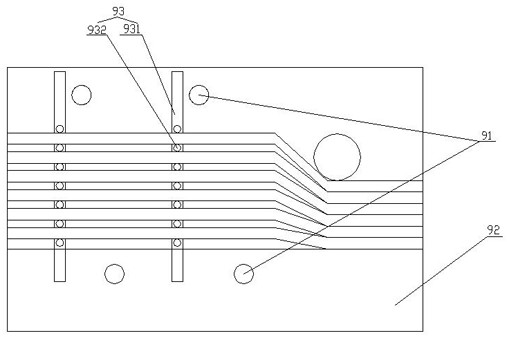

[0032] A kind of production technology of antibacterial and skin-friendly multi-effect wet wipes of the present embodiment, such as figure 1 As shown, the wet tissue consists of a first air-permeable layer 1, a second air-permeable layer 2 and a grid layer 3 placed between the first air-permeable layer 1 and the second air-permeable layer 2, as figure 2 As shown, the specific steps include:

[0033] S1. Production of non-woven fabrics: a. Mix natural wood fibers and chemical fibers to form fiber raw materials, open and mix the fiber raw materials and card them into fiber webs through a carding machine, and spunlace the front and back sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com