Design and preparation method of multi-layer composite structural NiTiCrBNb-based self-lubricating material for slide plate

A self-lubricating material and multi-layer composite technology, which is applied in the direction of metal processing equipment, chemical instruments and methods, layered products, etc., can solve the problems of inability to achieve lubricating effect, insufficient stiffness and hardness, poor anti-wear performance, etc., and achieve good Effects of lubricating performance and fixed molding function, small coefficient of friction, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

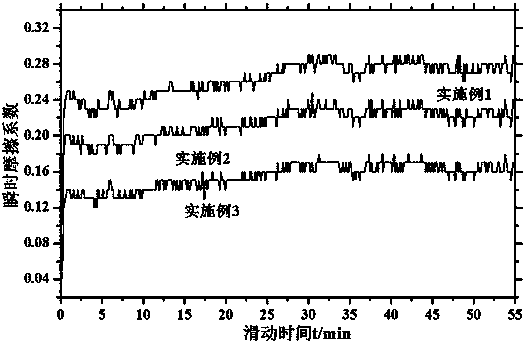

Embodiment 1

[0028] A multi-layer composite structure NiTiCrBNb-based sliding plate self-lubricating material is based on NiTiCrBNb-based alloy, curing agent, friction reducer, anti-wear agent, buffer material as raw materials, multi-layer composite structure is divided into friction film contact layer thickness, friction film support layer , four layers of friction film transition layer and base layer, the thickness volume percentage of each layer is 8% of friction film contact layer, 17% of friction film support layer, 30% of friction film transition layer and 45% of base layer.

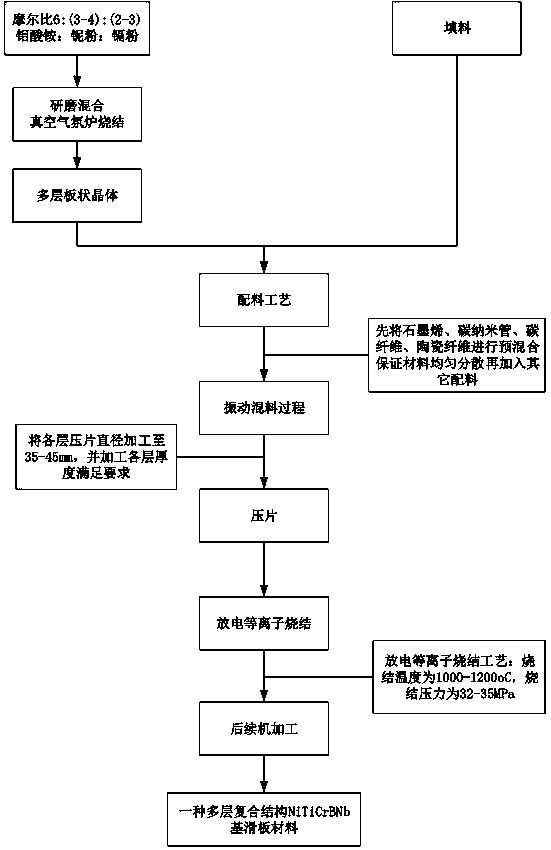

[0029] like figure 1 As shown, a kind of multi-layer composite structure NiTiCrBNb base sliding plate self-lubricating material and its preparation method specifically include the following steps:

[0030]1) Preparation of multi-layer plate crystal MoNbCrO: select ammonium molybdate, niobium powder and cadmium powder with a particle size of 22 μm, weigh the original powder with a molar ratio of 6:3:2, and obtai...

Embodiment 2

[0038] A multilayer composite structure NiTiCrBNb-based sliding plate self-lubricating material uses NiTiCrBNb-based alloy, curing agent, friction reducer, anti-wear agent, and buffer material as raw materials. The multilayer composite structure is divided into a friction film contact layer, a friction film support layer, and a friction film. The film transition layer and the base layer are four layers, the friction film contact layer is 10%, the friction film support layer is 20%, the friction film transition layer is 25% and the base layer is 45%.

[0039] like figure 1 As shown, a kind of multi-layer composite structure NiTiCrBNb base sliding plate self-lubricating material and its preparation method specifically include the following steps:

[0040] 1) Preparation of multi-layer plate crystal MoNbCrO: Select ammonium molybdate, niobium powder and cadmium powder with a particle size of 26 μm, weigh the original powder with a molar ratio of 6:4:3, and obtain molybdenum by gr...

Embodiment 3

[0048] A multilayer composite structure NiTiCrBNb-based sliding plate self-lubricating material uses NiTiCrBNb-based alloy, curing agent, friction reducer, anti-wear agent, and buffer material as raw materials. The multilayer composite structure is divided into a friction film contact layer, a friction film support layer, and a friction film. The film transition layer and the base layer are four layers, the friction film contact layer is 8%, the friction film support layer is 20%, the friction film transition layer is 30% and the base layer is 42%.

[0049] like figure 1 As shown, a kind of multi-layer composite structure NiTiCrBNb base sliding plate self-lubricating material and its preparation method specifically include the following steps:

[0050] 1) For the preparation of multi-layer plate crystal MoNbCrO, select ammonium molybdate, niobium powder and cadmium powder with a particle size of 24 μm, weigh the original powder according to the molar ratio of 6:3:3, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com