Aramid fiber filter bag for dedusting and filtering industrial waste gas

An industrial waste gas and filter bag technology, applied in the field of aramid filter bags, can solve the problems of difficult filter bag dust cleaning, cumbersome disassembly process, filter bag damage, etc., to achieve multi-stage filtration, avoid clogging, and facilitate cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

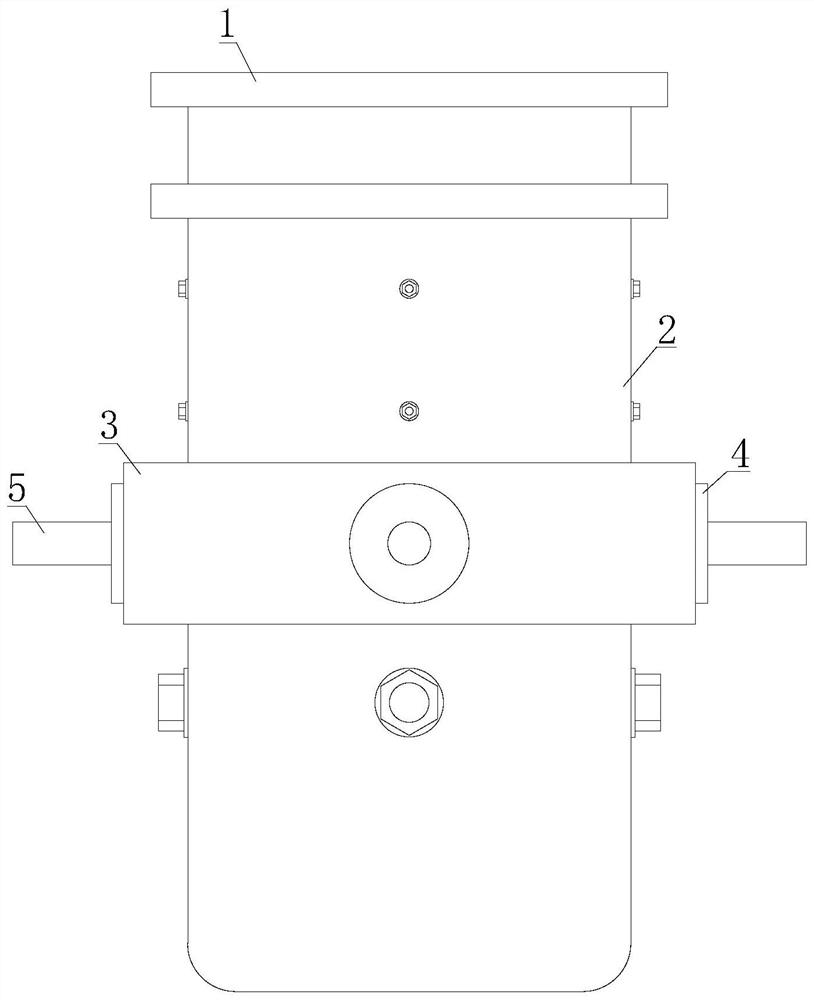

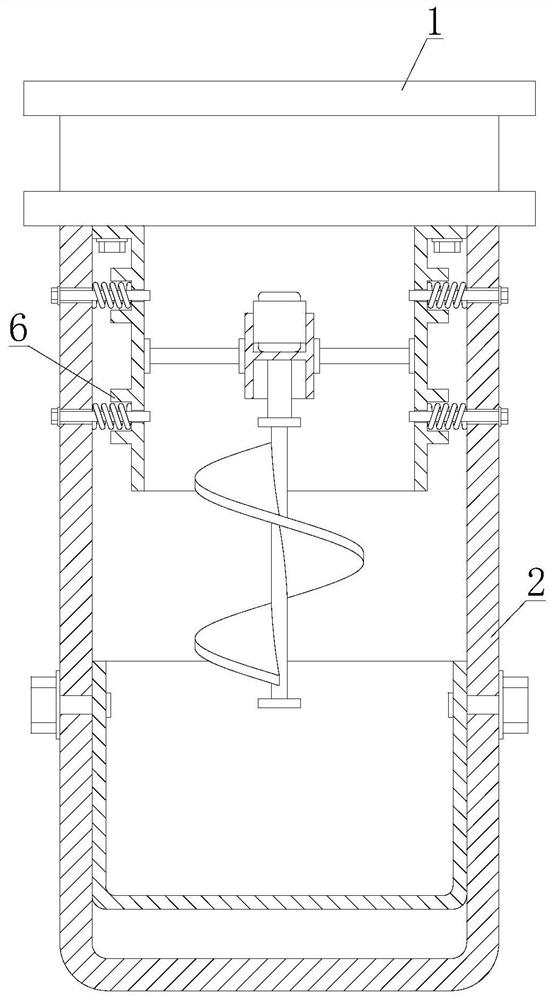

[0026] see Figure 1-Figure 2 , an aramid filter bag used for dust removal and filtration of industrial waste gas, including a filter bag installation port 1, an external filter bag 2, a sliding fixing hoop 3, a screw base 4, a fixing screw rod 5 and an absorption assembly 6, and a filter bag installation port 1 Absorbing assembly 6 is installed at the bottom of the absorbing assembly 6, and external filter bag 2 is installed on the outside of the absorbing assembly 6, and sliding fixing hoop 3 is installed on the outer side of external filtering bag 2, and screw base 4 is arranged on sliding fixing hoop 3, and fixing screw 5.

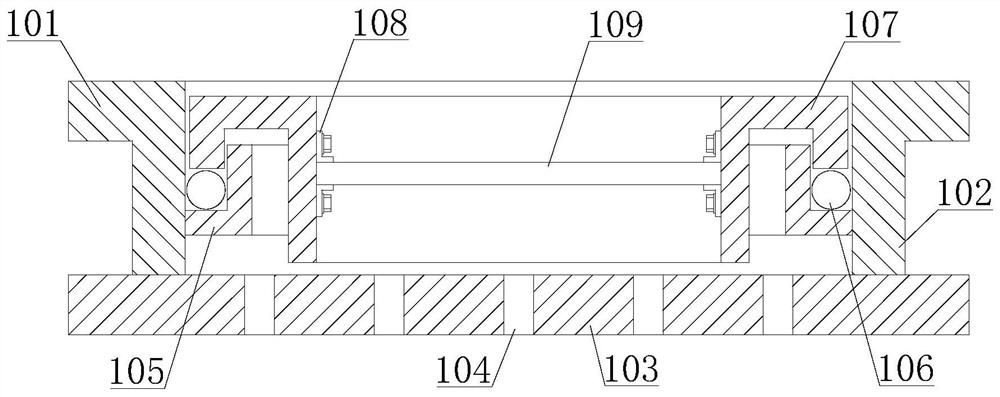

[0027] see image 3 The filter bag installation port 1 includes an outer clamping plate 101, an installation sleeve 102, a bottom connecting plate 103, a connecting plate through hole 104, an inner nesting tube 105, a sliding ball 106, a filter sleeve 107, a fixed flap 108 and The filter sieve plate 109 is provided with an installation sleeve 102 on ...

Embodiment 2

[0031] see Figure 1-Figure 2, an aramid filter bag used for dust removal and filtration of industrial waste gas, including a filter bag installation port 1, an external filter bag 2, a sliding fixing hoop 3, a screw base 4, a fixing screw rod 5 and an absorption assembly 6, and a filter bag installation port 1 Absorbing assembly 6 is installed at the bottom of the absorbing assembly 6, and external filter bag 2 is installed on the outside of the absorbing assembly 6, and sliding fixing hoop 3 is installed on the outer side of external filtering bag 2, and screw base 4 is arranged on sliding fixing hoop 3, and fixing screw 5.

[0032] see Figure 4 The filter bag installation port 1 includes an outer clamping plate 101, an installation sleeve 102, a bottom connecting plate 103, a connecting plate through hole 104, an inner nesting tube 105, a sliding ball 106, a filter sleeve 107, a fixed flap 108 and The filter sieve plate 109 is provided with an installation sleeve 102 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com