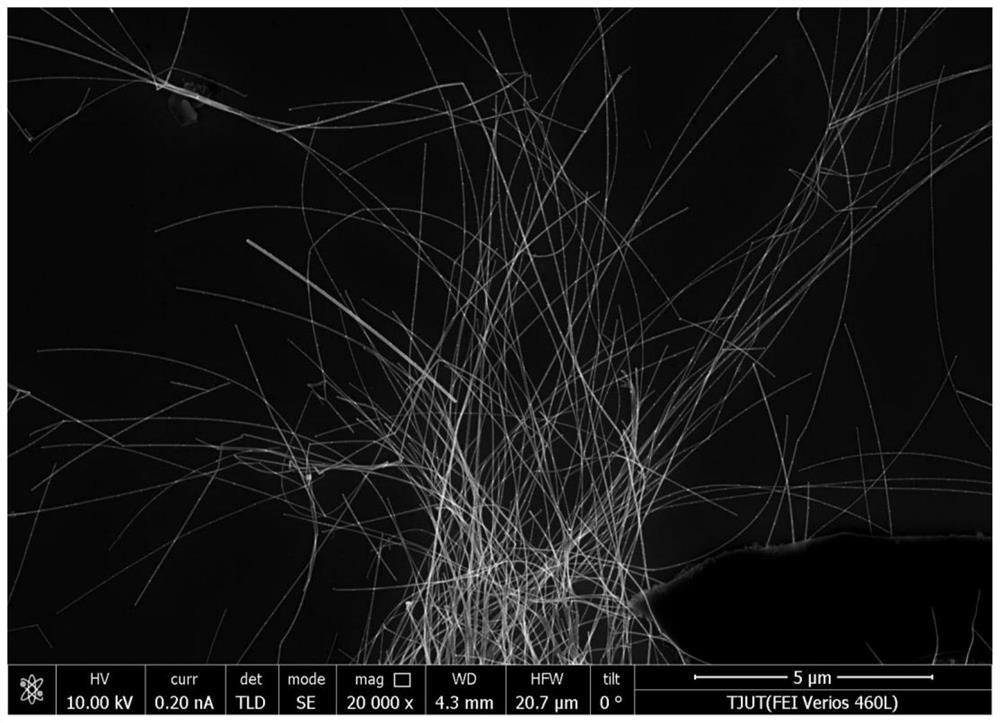

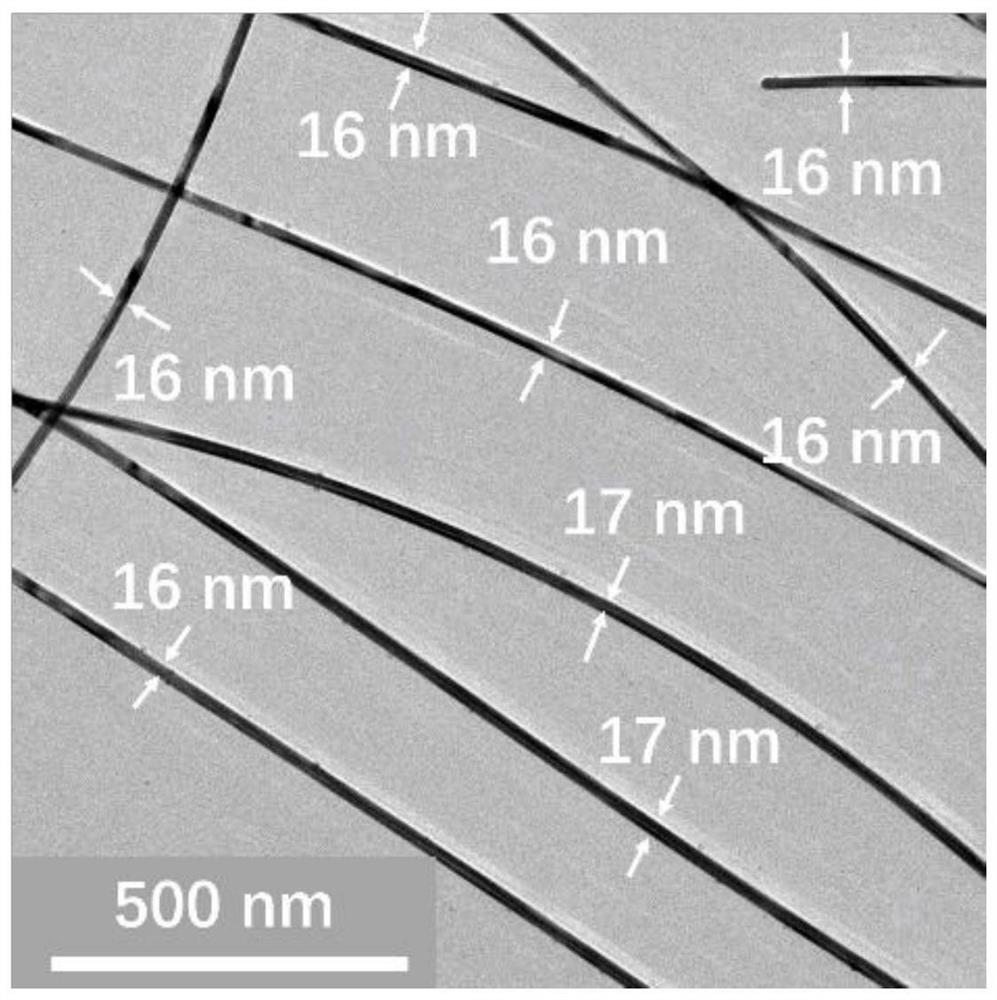

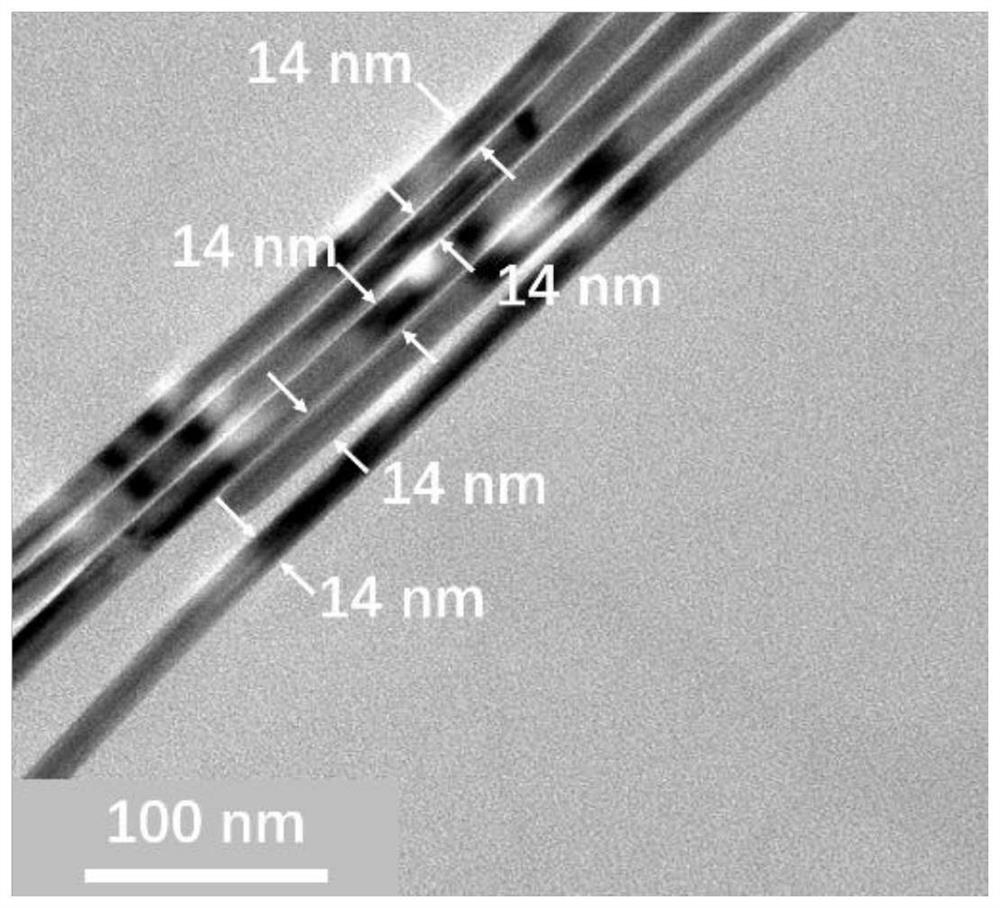

Large-scale preparation and purification method for superfine silver nanowires

A purification method and nanowire technology, which is applied in the field of large-scale preparation and purification of ultra-fine silver nanowires, can solve the problems of high surface tension of aqueous dispersions, inability to alleviate blocking problems, and affect film-forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for large-scale preparation and purification of ultrafine silver nanowires, comprising the following steps:

[0051] Step 1. Mix 285mL of ethylene glycol and 150mL of diethylene glycol, add 15g of polyvinylpyrrolidone with an average molecular weight of 1300000, stir at 1200r / min for 60min to dissolve, then add 2.8g of silver nitrate, stir at 1200r / min for 60min to dissolve the silver nitrate, Then add 50mL of 1.17mM tetrabutylammonium chloride, 100mL of 1.17mM tetrabutylammonium bromide, continue stirring at 1200r / min for 45min, add 1.5mL of 0.017M ferric trichloride hexahydrate to obtain a reaction solution, and the reaction solution Pour into the polytetrafluoroethylene liner, put the polytetrafluoroethylene liner into the reaction kettle, heat to 160 ° C for 180 minutes of reaction, and naturally cool to room temperature after the reaction to obtain the ultrafine silver nanowire mother liquor;

[0052] Step 2, diluting the ultrafine silver nanowire mother s...

Embodiment 2

[0063] A method for preparing ultrafine silver nanowires, comprising the following steps:

[0064]Step 1. Mix 285mL of ethylene glycol and 150mL of diethylene glycol, add 15g of polyvinylpyrrolidone with an average molecular weight of 1300000, stir at 1200r / min for 60min to dissolve, then add 2.8g of silver nitrate, stir at 1200r / min for 60min to dissolve the silver nitrate, Then add 40mL of 1.17mM tetrabutylammonium chloride and 80mL of 1.17mM tetrabutylammonium bromide, continue to stir at 1200r / min for 45min, add 1.5mL of 0.017M ferric trichloride hexahydrate to obtain a reaction solution, and the reaction solution Pour into the polytetrafluoroethylene liner, put the polytetrafluoroethylene liner into the reaction kettle, heat to 160 ° C for 180 minutes of reaction, and naturally cool to room temperature after the reaction to obtain the ultrafine silver nanowire mother liquor;

[0065] Step 2, diluting the ultrafine silver nanowire mother solution to 1 time to obtain a dilu...

Embodiment 3

[0076] A method for preparing ultrafine silver nanowires, comprising the following steps:

[0077] Step 1. Mix 285mL of ethylene glycol and 150mL of diethylene glycol, add 15g of polyvinylpyrrolidone with an average molecular weight of 1300000, stir at 1200r / min for 60min to dissolve, then add 2.8g of silver nitrate, stir at 1200r / min for 60min to dissolve the silver nitrate, Then add 40mL of 1.17mM tetrabutylammonium chloride and 80mL of 1.17mM tetrabutylammonium bromide, continue to stir at 1200r / min for 45min, then subject the mixture to ultrasonic treatment under pressure for 15min, and then add 1.5 mL0.017M ferric trichloride hexahydrate to obtain the reaction solution, pour the reaction solution into the polytetrafluoroethylene lining, put the polytetrafluoroethylene lining into the reaction kettle, heat to 160°C for 180min, after the reaction Naturally cool to room temperature to obtain ultra-fine silver nanowire mother liquor; pressurized ultrasonic treatment condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Electric field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com