Preparation method of wear-resistant and high-temperature-resistant vision window glass and prepared vision window glass

A technology of window glass and high temperature resistance, which is applied in the field of window glass, which can solve the problems that window glass cannot meet the needs of 3D printer equipment, and achieve the effects of high activity and easy dispersion, excellent scratch resistance, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

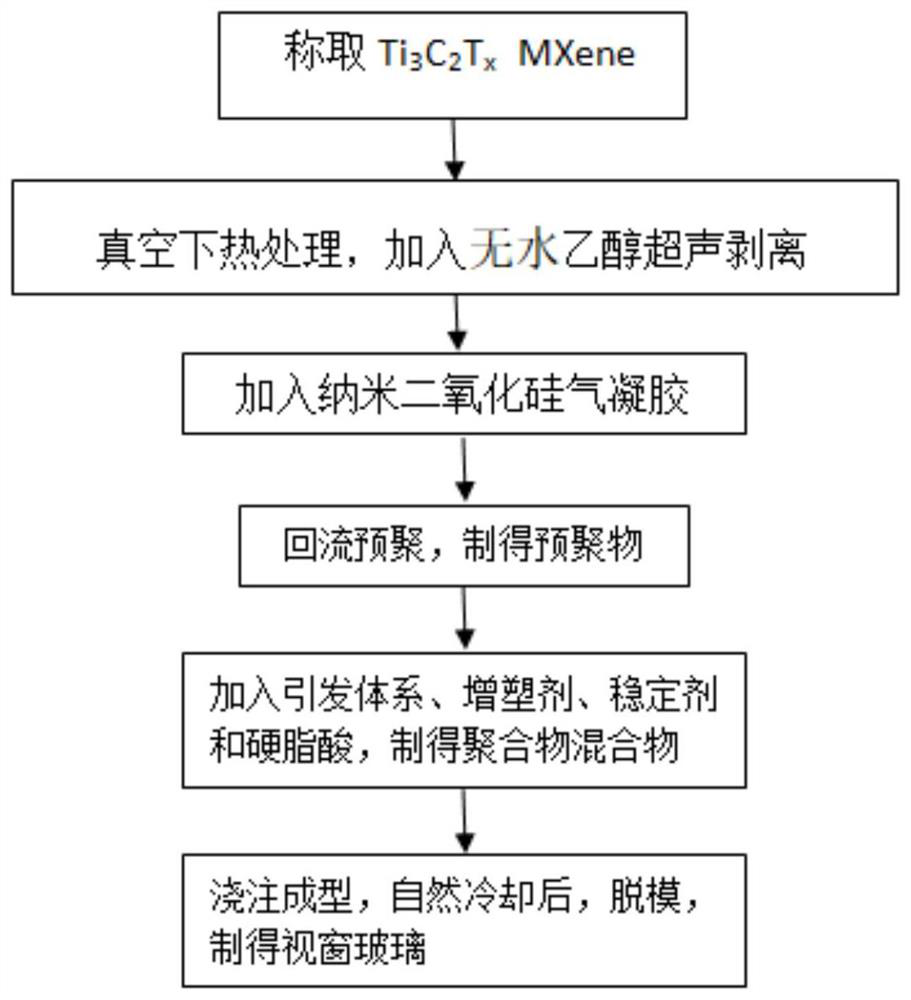

[0027] A method for preparing a wear-resistant and high-temperature resistant window glass, characterized in that it comprises the following steps:

[0028] S1. Preparation of prepolymer: weigh 0.05kg nanosheet Ti 3 C 2 T x MXene, heat treatment at 200 ° C for 30 min under vacuum conditions, to obtain TiO 2 / Ti 3 C 2 T x MXene complex, the complex was added to 100kg of absolute ethanol and stirred evenly, ultrasonically stripped for 10h, the ultrasonic frequency was 40kHz, and a colloidal solution was obtained;

[0029] S2. Add 2kg of γ-aminopropyltriethoxysilane to the colloidal solution prepared in step S1, stir evenly, and add 20kg of dry nano-silica airgel with a particle size of 10-100nm, ultrasonically disperse, and ultrasonically 20min, the ultrasonic frequency is 20kHz, and the silica airgel / TiO 2 / Ti 3 C 2 T x MXene nanocomposite colloidal solution, add 100kg methyl methacrylate and 10kgα-methylstyrene to the above composite colloidal solution, reflux pre...

Embodiment 2

[0033] A method for preparing a wear-resistant and high-temperature resistant window glass, characterized in that it comprises the following steps:

[0034] S1. Preparation of prepolymer: weigh 0.05kg nanosheet Ti 3 C 2 T xMXene, heat treatment at 200 ° C for 30 min under vacuum conditions, to obtain TiO 2 / Ti 3 C 2 T x MXene complex, the complex was added to 50kg of absolute ethanol and stirred evenly, ultrasonically stripped for 10h, the ultrasonic frequency was 40kHz, and a colloidal solution was obtained;

[0035] S2. Add 4kg of γ-aminopropyltriethoxysilane to the colloidal solution prepared in step S1, stir evenly, and add 30kg of dry nano-silica airgel with a particle size of 10-100nm, ultrasonically disperse, and ultrasonically 10min, the ultrasonic frequency is 30kHz, and the silica airgel / TiO 2 / Ti 3 C 2 T x MXene nanocomposite colloidal solution, add 100kg methyl methacrylate and 5kgα-methylstyrene to the above composite colloidal solution, reflux prepoly...

Embodiment 3

[0039] A method for preparing a wear-resistant and high-temperature resistant window glass, characterized in that it comprises the following steps:

[0040] S1. Preparation of prepolymer: weigh 0.05kg nanosheet Ti 3 C 2 T x MXene, heat treatment at 200 ° C for 30 min under vacuum conditions, to obtain TiO 2 / Ti 3 C 2 T x MXene complex, the complex was added to 90kg of absolute ethanol and stirred evenly, ultrasonically stripped for 10h, the ultrasonic frequency was 40kHz, and a colloidal solution was obtained;

[0041] S2. Add 2.5kg of γ-aminopropyltriethoxysilane to the colloidal solution prepared in step S1, stir evenly and add 22kg of dry nano-silica airgel with a particle size of 10-100nm, ultrasonically disperse, and ultrasonically 18min, ultrasonic frequency is 22kHz, prepared silica airgel / TiO 2 / Ti 3 C 2 T x MXene nanocomposite colloidal solution, add 100kg methyl methacrylate and 8kgα-methylstyrene to the above composite colloidal solution, reflux prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com