Preparation method of petal-shaped ZnIn2S4-loaded bismuth oxide composite visible light catalytic material and product prepared by preparation method

A catalytic material, znin2s4 technology, applied in the field of photocatalytic materials, can solve the problems of poor light response, limited photocatalytic ability, and high photo-generated charge recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

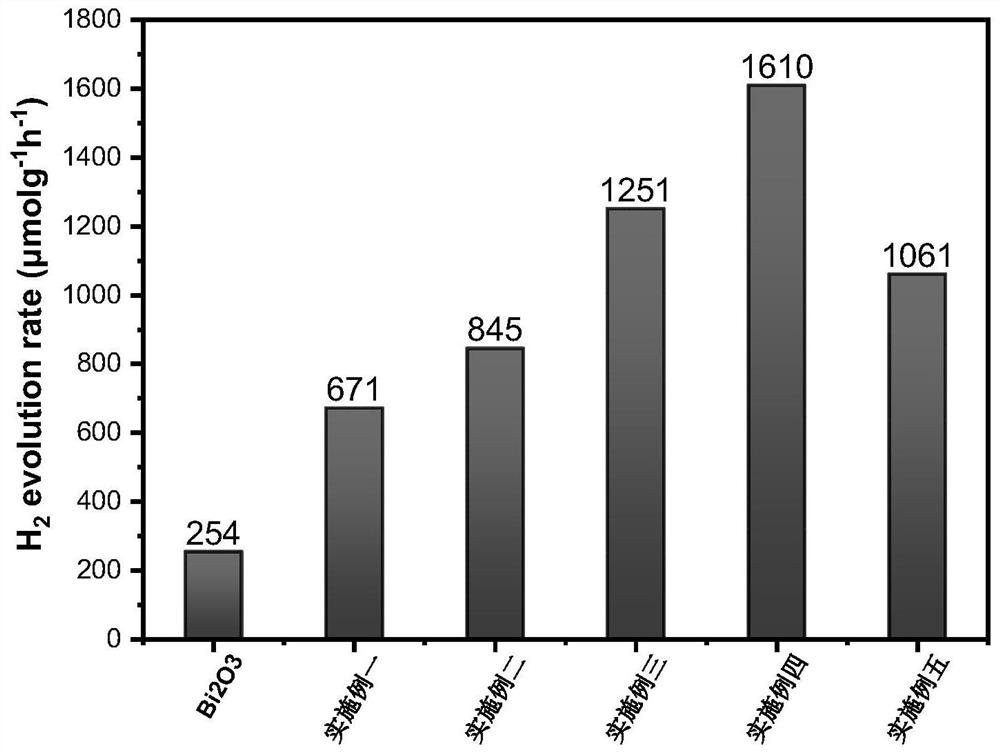

Embodiment 1

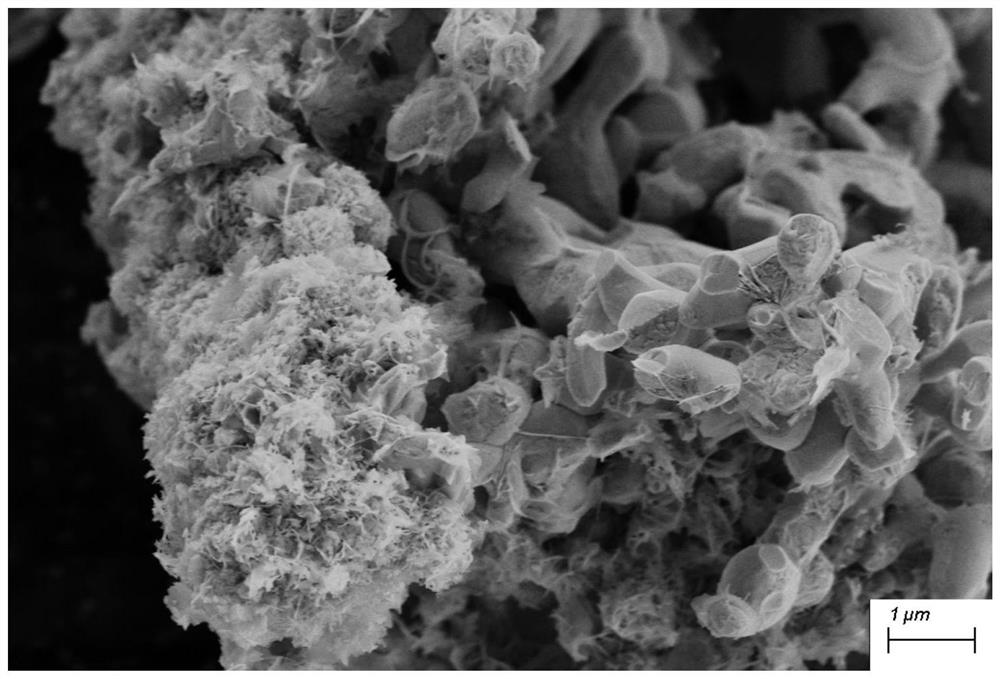

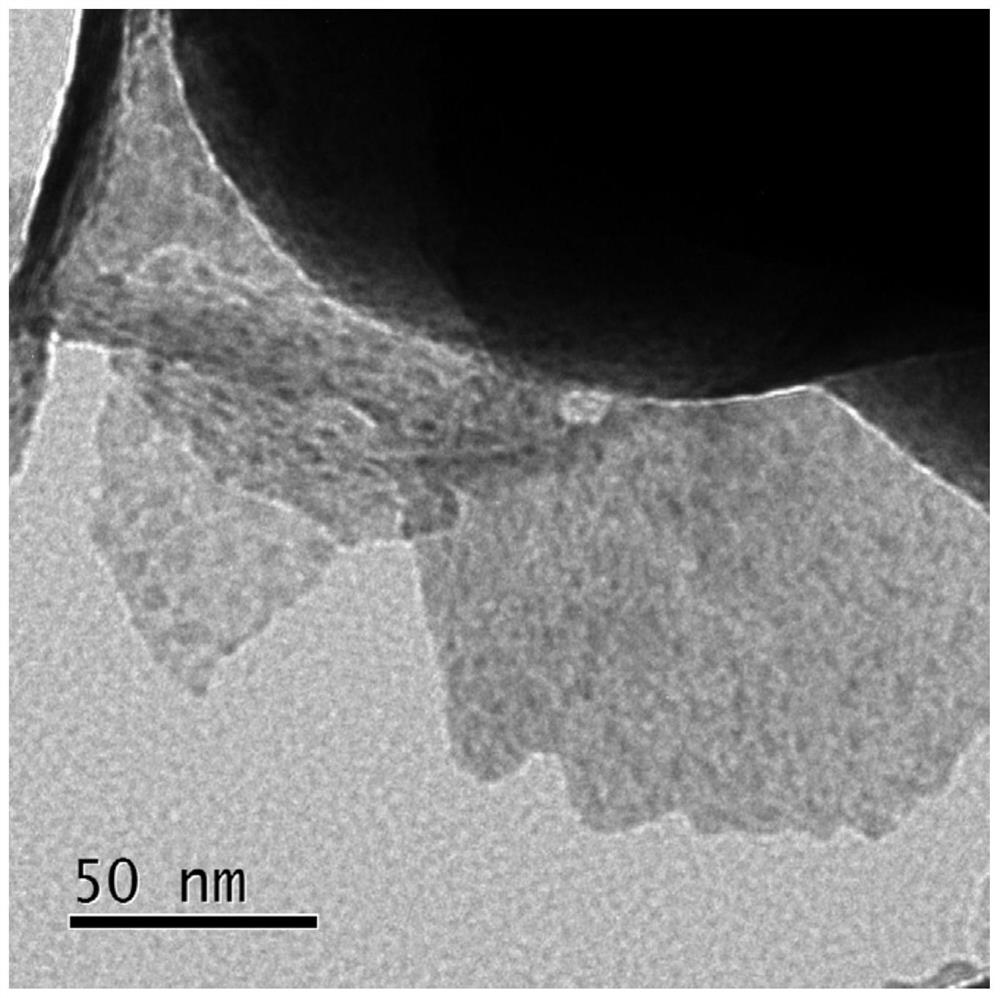

[0025] A kind of load petal shape ZnIn of this embodiment 2 S 4 The preparation method of bismuth oxide composite visible light catalytic material, its steps are as follows:

[0026] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0027] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0028] (1-2) Transfer the above mixed solution into a reaction kettle and react at 120°C for 24 hours. After the reaction product is cooled, wash it with DMF and methanol for 3 times, and then put it in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0029] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace, and calcinate it at 500°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

[0030] (2)ZnIn 2 S 4 preparation of

[0031] (2-1) ...

Embodiment 2

[0036] A kind of load petal shape ZnIn of this embodiment 2 S 4 The preparation method of bismuth oxide composite visible light catalytic material, its steps are as follows:

[0037] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0038] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0039] (1-2) Transfer the above mixed solution into a reaction kettle and react at 130°C for 20 hours. After the reaction product is cooled, wash it with DMF and methanol for 3 times, and then put it in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0040] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace and calcinate it at 520°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

[0041] (2)ZnIn 2 S 4 preparation of

[0042] (2-1) Dis...

Embodiment 3

[0047] A kind of load petal shape ZnIn of this embodiment 2 S 4 The preparation method of bismuth oxide composite visible light catalytic material, its steps are as follows:

[0048] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0049] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0050] (1-2) Transfer the above mixed solution into a reaction kettle and react at 140°C for 12 hours. After the reaction product is cooled, it is washed with DMF and methanol for 3 times, and then placed in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0051] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace, and calcinate it at 550°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

[0052] (2)ZnIn 2 S 4 preparation of

[0053] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com