Numerical control graphite electrode and joint precision machining, detecting, assembling and packaging automation line

A graphite electrode and precision machining technology, which is applied in the fields of automatic packaging control, stone processing equipment, stone processing tools, etc., can solve the problems of high assembly labor intensity, large volume, and imperfect processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

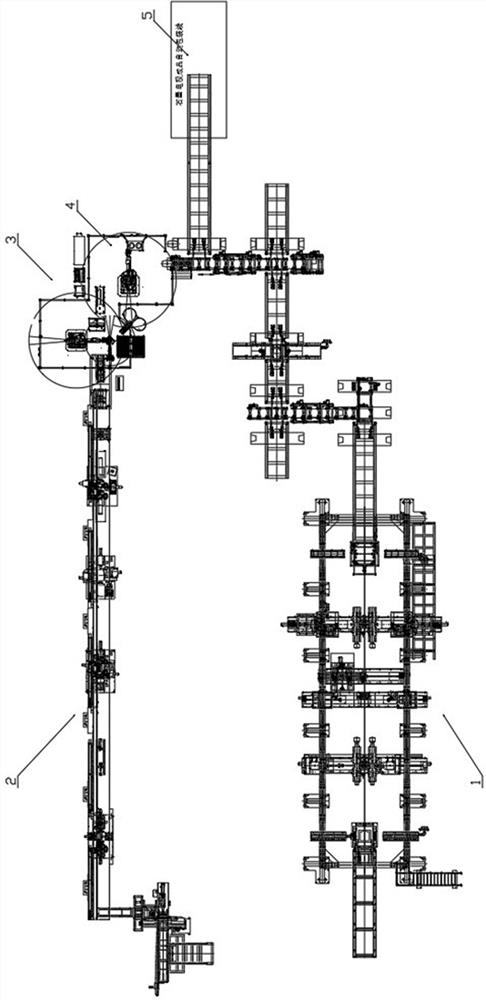

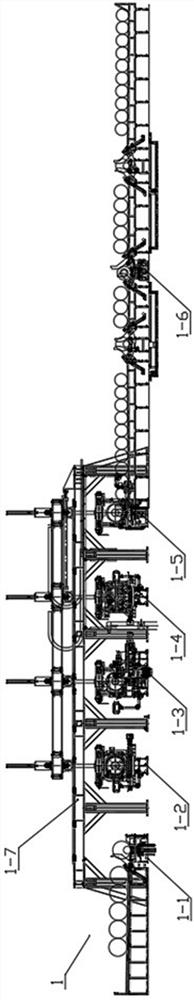

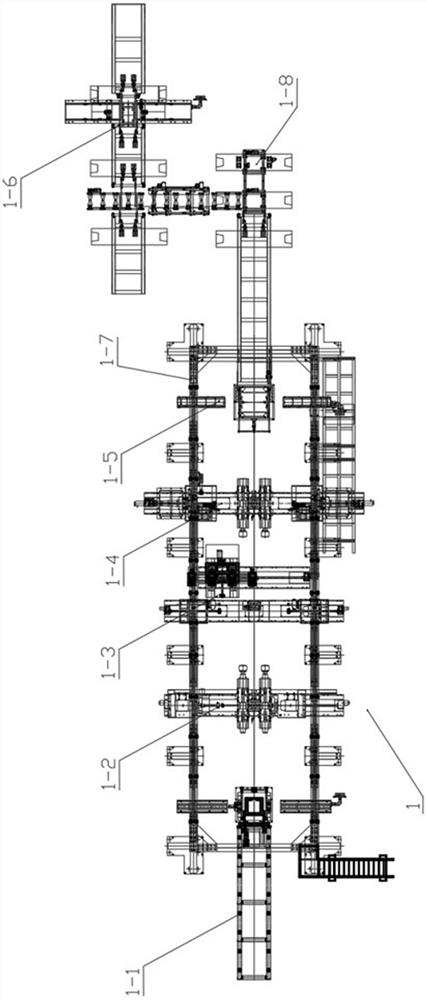

[0159] Refer to attached Figure 1-13 , CNC graphite electrode and joint precision processing detection assembly and packaging automatic line consists of graphite electrode automatic processing line 1, truss conveying graphite joint automatic processing line 2, graphite joint robot automatic spring spring bolting machine 3, graphite electrode and joint robot automatic assembly Installation 4. Automatic packaging line for finished graphite electrodes (including joints) 5.

[0160] Graphite joint robot automatic circlip bolting machine 3 is set on the truss-conveyed graphite joint processing line (graphite joint automatic processing line) 2 finished product output front end, graphite electrode and joint robot automatic assembly machine 4 is set on graphite electrode automatic processing line 1 and Between the truss conveying type graphite joint processing line (graphite joint automatic processing line) 2. The graphite electrode finished product packaging line 5 is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com