Preparation method of bone china low-temperature hard glaze

A porcelain, low-temperature technology, applied in the field of preparation of bone china low-temperature hard glaze, can solve the problems of difficult cleaning, poor acid and alkali resistance, poor stain resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A low-temperature hard glaze for bone china, consisting of the following mass fraction raw materials: Li 2 O: 0.48%, B 2 o 3 : 5.03%, CaO; 8.00%, ZnO: 8.76%, K 2 O: 5.70%, Na 2 O: 4.12%, SiO 2 :57.47%, Al 2 o 3 : 10.44%.

[0024] Weigh each raw material according to the mass fraction, mix them evenly and put them into a high-temperature furnace, fully melt them at 1400°C, and put the uniformly melted melt directly into water to quench to obtain a frit, add 2% Suzhou soil to the frit, Wet balls are ground into a glaze slurry in a ball mill for glazing operation, and glaze firing is carried out at 1080°C to obtain a low-temperature hard glaze for bone china. The hardness of the glazed surface reaches 6.3GPa, and the acid and alkali resistance of the glazed surface reaches the grade A of acid and alkali resistance of the glazed surface of daily-use ceramics.

Embodiment 2

[0026] A low-temperature hard glaze for bone china, consisting of the following mass fraction raw materials: Li 2 O: 0.48%, B 2 o 3 : 5.03%, CaO; 8.00%, ZnO: 8.76%, K 2 O: 5.70%, Na 2 O: 4.12%, SiO 2 :57.47%, Al 2 o 3 : 10.44%.

[0027] Weigh each raw material according to the mass fraction, mix them evenly and put them into a high-temperature furnace, fully melt them at 1400°C, and put the uniformly melted melt directly into water to quench to obtain a frit, add 2% Suzhou soil to the frit, Wet balls are ground into a glaze slurry in a ball mill for glazing operation, and glaze firing is carried out at 1150°C to obtain a low-temperature hard glaze for bone china. The hardness of the glazed surface reaches 6.3GPa, and the acid and alkali resistance of the glazed surface reaches the grade A of acid and alkali resistance of the glazed surface of daily-use ceramics.

Embodiment 3

[0029] Utilize the bone china low-temperature hard glaze prepared by embodiment 1 to burn moonlight 8-inch flat dish, comprising the following steps:

[0030] (1) make the green body with bone china material;

[0031] (2) high-temperature bisque firing of the above green body at 1250°C;

[0032](3) Use the bone china low-temperature hard glaze prepared in Example 1 on the product after bisque firing to carry out medium-temperature glaze firing after glazing, and the glaze firing temperature is 1050° C. to obtain a finished moonlight 8-inch flat plate.

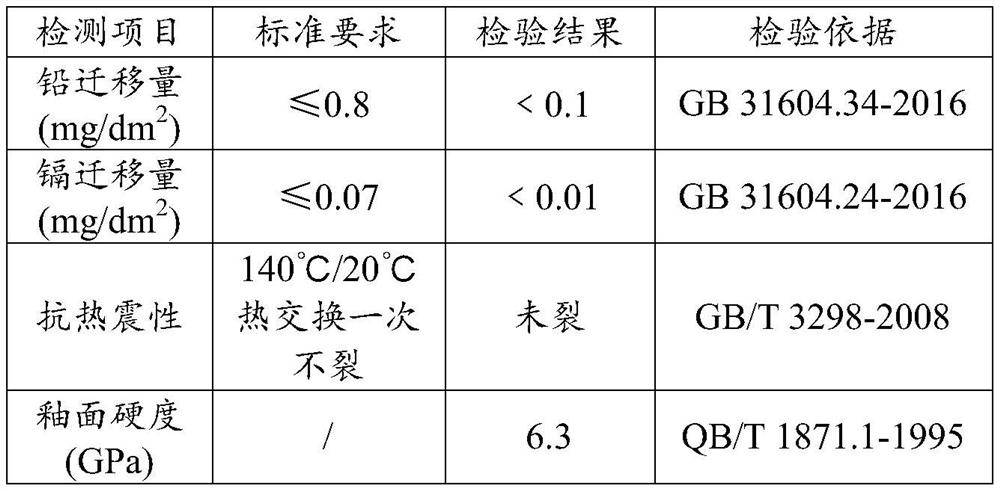

[0033] The finished moonshine 8-inch flat plate was tested for performance indicators such as lead migration, cadmium migration, thermal shock resistance, and glaze hardness. The test results are shown in Table 1: The indicators tested for this sample are lead migration, cadmium migration It meets the requirements of the migration test conditions for products used under normal temperature conditions in GB 4806.4-2016 "National...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com