Phosphogypsum soil conditioner and preparation method thereof

A soil conditioner, phosphogypsum technology, applied in soil conditioning materials, chemical instruments and methods, and restoration of polluted soils, etc., can solve problems such as difficulty in achieving pre-set effects, weak heavy metal processing capacity, and single reactant situation. , to achieve the effect of reducing heavy metal ions, rich mineral content, and reducing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

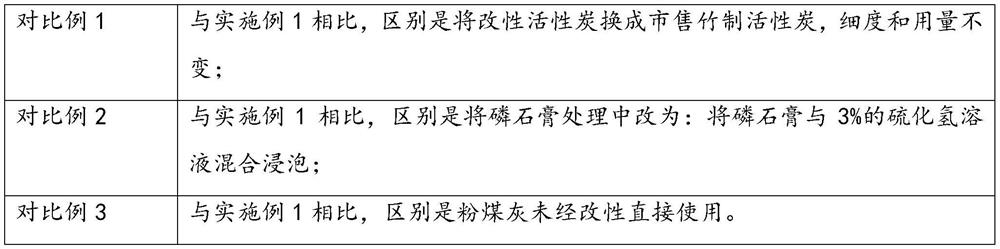

Examples

Embodiment 1

[0021] A phosphogypsum soil improver, prepared from the following raw materials: phosphogypsum treated with active microorganisms as a carrier, formulated by adding modified activated carbon and an adsorbent; the mass of the phosphogypsum accounts for 40% of the total mass of the improver The mass ratio of the modified activated carbon to phosphogypsum is 1:3; the balance is an adsorbent; the phosphogypsum treated by the active microorganisms is obtained by mixing and soaking the fermented liquid of methane bacteria and phosphogypsum according to the mass ratio of 1:0.3 , the methane bacteria fermentation liquid is biogas slurry;

[0022] The preparation method of the phosphogypsum treated with active microorganisms is as follows: process the phosphogypsum into a powder with a fineness of 30 meshes, heat it to 30°C, mix and soak it with the biogas slurry for 3 hours; after filtering, pour the biogas slurry into a fermentation tank for fermentation, and continue Add new biogas ...

Embodiment 2

[0026] A phosphogypsum soil improver, prepared from the following raw materials: using phosphogypsum treated with active microorganisms as a carrier, adding modified activated carbon and an adsorbent; the mass of the phosphogypsum accounts for 60% of the total mass of the improver The mass ratio of the modified activated carbon to phosphogypsum is 1:5; the balance is adsorbent; the phosphogypsum treated by the active microorganisms is obtained by mixing and soaking the fermented liquid of methane bacteria and phosphogypsum according to the mass ratio of 1:0.4 , the methane bacteria fermentation liquid is biogas slurry;

[0027] The preparation method of the phosphogypsum treated with active microorganisms is as follows: process the phosphogypsum into a powder with a fineness of 50 meshes, heat it to 35°C, mix and soak it with the biogas slurry for 5 hours; after filtering, pour the biogas slurry into a fermentation tank for fermentation, continue Add new biogas slurry and phos...

Embodiment 3

[0031] A phosphogypsum soil improver, prepared from the following raw materials: using phosphogypsum treated with active microorganisms as a carrier, adding modified activated carbon and an adsorbent; the mass of the phosphogypsum accounts for 57% of the total mass of the improver The mass ratio of the modified activated carbon to phosphogypsum is 1:4; the balance is adsorbent; the phosphogypsum treated by the active microorganisms is obtained by mixing and soaking the fermented liquid of methane bacteria and phosphogypsum according to the mass ratio of 1:0.34 , the methane bacteria fermentation liquid is biogas slurry;

[0032] The preparation method of the phosphogypsum treated with active microorganisms is as follows: process the phosphogypsum into a powder with a fineness of 40 meshes, heat it to 33°C, mix and soak it with the biogas slurry for 4 hours; after filtering, pour the biogas slurry into a fermentation tank for fermentation, and continue Add new biogas slurry and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com