Spiral drilling grouting structure and grouting control system thereof

A technology of control system and helical drill rod, which is applied in the direction of rotary drilling, percussion drilling, rotary drilling rigs, etc., can solve the problems of heavy weight, high torque requirements of drilling rigs, and different raw material particles, so as to improve efficiency, The effect of reducing manufacturing cost and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

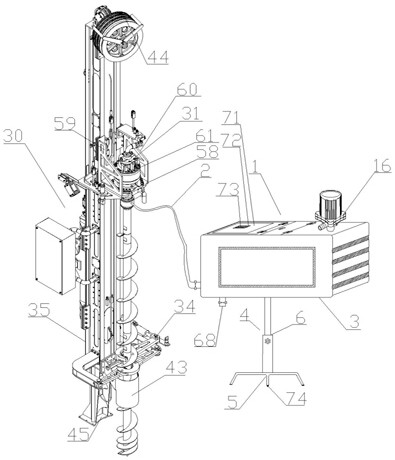

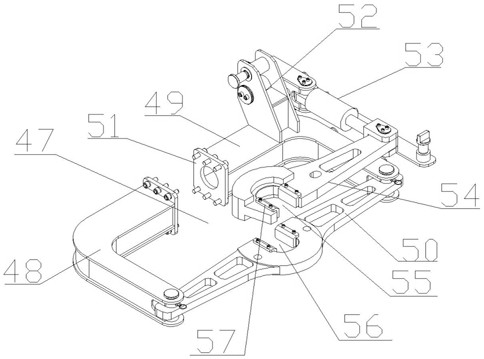

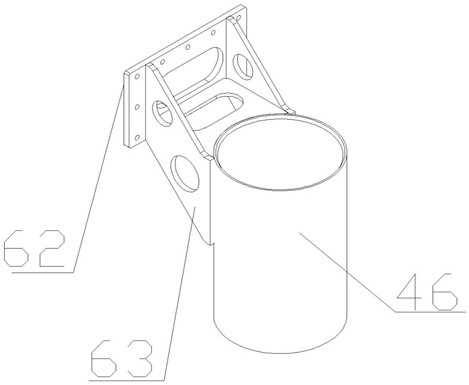

[0034] Such as Figure 1~10 As shown, the auger drills into the grouting structure and its grouting control system, which includes a grouting control system 1, and the grouting control system 1 includes a grouting hose 2 and a grouting device 3, and the grouting device 3 The bottom is provided with a lifting device 4, and the setting of the lifting device 4 enables the grouting control system to adjust its height according to the environment. The lifting device 4 includes three claws 5 and a telescopic rod 6. Connected, the grouting device 3 is a structure with a cavity inside, and the inside of the cavity is provided with a first cavity 7, a second cavity 8 and a third cavity 9;

[0035] The inside of the first cavity 7 is provided with a stirring system and a feeding system cooperating with the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com