Solvent-free polymer ion conductor as well as preparation method and application thereof

A technology of ionic conductors and polymers, applied in the direction of organic material conductors, cable/conductor manufacturing, conductors, etc., can solve the problems of high ionic conductivity and low room temperature ionic conductivity, and achieve high ionic conductivity, simple operation, and good performance. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The first aspect of the present invention provides a method for preparing a solvent-free polymer ion conductor. The method includes: first contacting an amino group or hydrazide-containing compound, an aldehyde compound, and an organic metal lithium salt in an organic solvent, and a reversible A Schiff base reaction to obtain a gel, and then drying the gel to obtain a solvent-free polymer ion conductor;

[0026] Wherein, at least one of the amino group or hydrazide-containing compound and the aldehyde compound is a polymer;

[0027] The amino group-containing compound is selected from at least one of polyoxyethylene diamine, polydimethylsiloxane diamine, s-phenylenediamine, and p-phenylenediamine, and the hydrazide-containing compound is selected from bis-p-phenylene diamine Benzohydrazide-terminated polyoxyethylene and / or N,N,N,N-tetrapropionylhydrazide-terminated polydimethylsiloxane;

[0028] The aldehyde compound is selected from at least one of trimesaldehyde, ter...

Embodiment 1

[0055] 1) Dissolve 400mg of polyoxyethylene diamine (P107103-5g, number average molecular weight 2000g / mol) and 0.328g of lithium bistrifluoromethanesulfonimide in 2mL of N,N-dimethyl In base formamide, mixed solution I is obtained;

[0056] 2) Dissolve 25 mg of trimesaldehyde in 300 μL of N,N-dimethylformamide at 60°C to obtain a mixed solution II;

[0057] 3) Mix the above-mentioned mixed solution I and the above-mentioned mixed solution II with a mixer, pour it into a polytetrafluoroethylene abrasive tool, remove air bubbles and react at room temperature for 2 hours to obtain a gel, and then place the obtained gel at 60°C Dry in a vacuum oven for 48 hours to completely volatilize the solvent N,N-dimethylformamide to obtain a solvent-free polymer ion conductor.

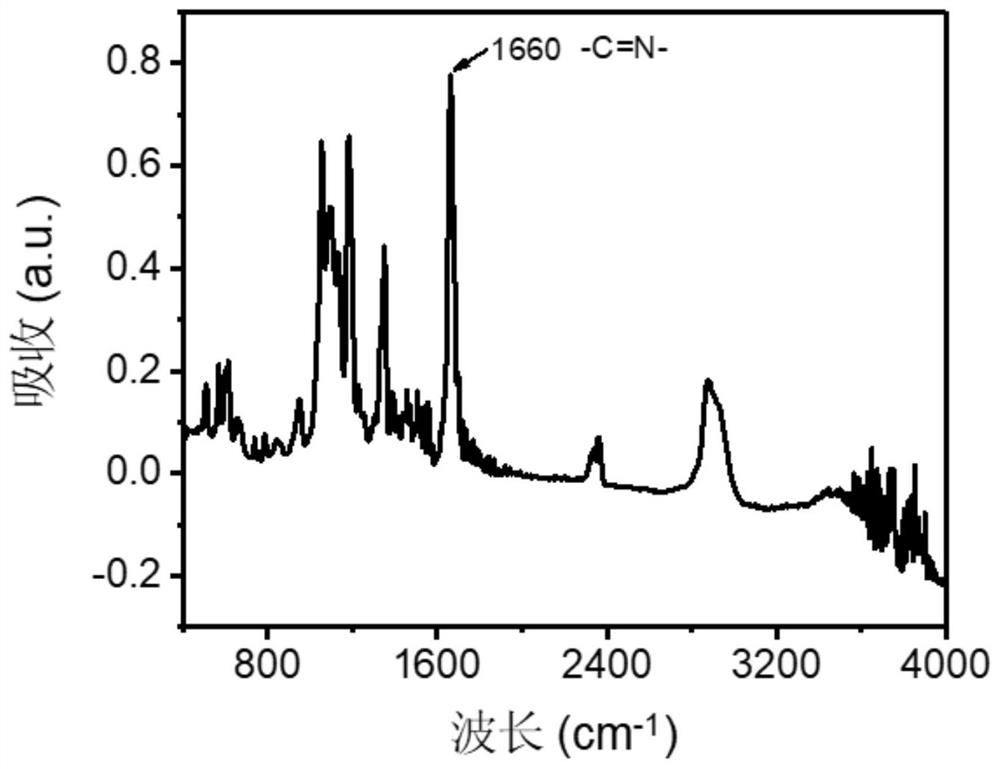

[0058] The solvent-free polymer ion conductor that embodiment 1 obtains carries out infrared spectroscopic analysis, and the result is as follows figure 1 Shown: by figure 1 It can be seen that 1646cm -1 The abs...

Embodiment 2

[0060] 1) Dissolve 2 g of polydimethylsiloxane diamine (DMS-A21, number average molecular weight: 5000 g / mol) and 0.6 g of lithium bistrifluoromethanesulfonyl imide in 1 mL of trichloro In methane, mixed liquid I was obtained;

[0061] 2) Dissolving 33 mg of trimesaldehyde in 300 μL of chloroform at room temperature to obtain a mixed solution II;

[0062] 3) Mix the above-mentioned mixed solution I and the above-mentioned mixed solution II with a mixer, pour it into a polytetrafluoroethylene abrasive tool, remove air bubbles and react at room temperature for 2 hours to obtain a gel, and then place the obtained gel at 60°C Dry in a vacuum oven for 48 hours, so that the solvent chloroform is completely volatilized, and a solvent-free polymer ion conductor is obtained.

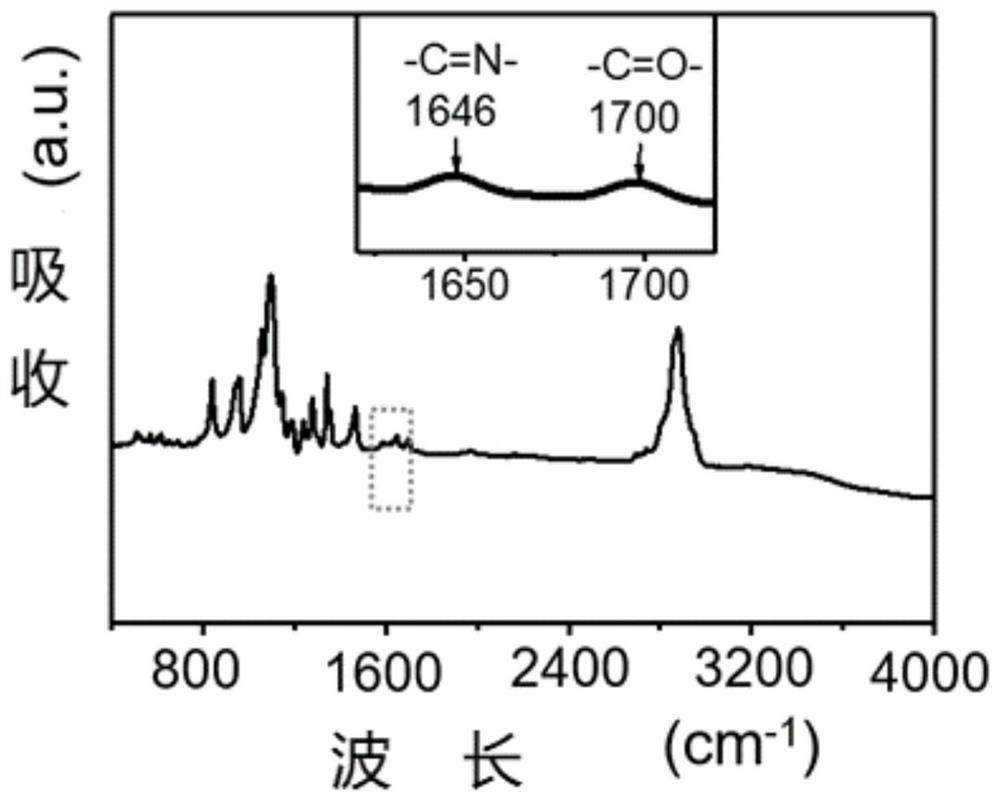

[0063] The obtained solvent-free polymer ion conductor was analyzed by infrared spectroscopy, and the results were as follows: figure 2 Shown: by figure 2 It can be seen that 1646cm -1 The absorption peak c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com