Flue gas desulfurization and denitrification integrated treatment method

A technology for desulfurization and denitrification and treatment methods, which is applied in the field of flue gas desulfurization and denitrification integrated treatment, and can solve the problems of low solubility and low solubility

Active Publication Date: 2021-09-10

深圳灏权环保有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

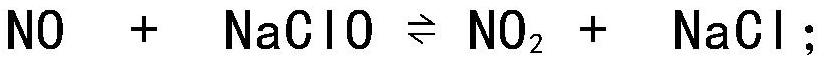

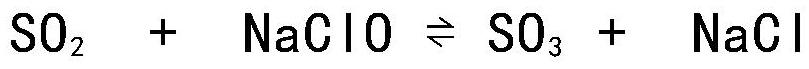

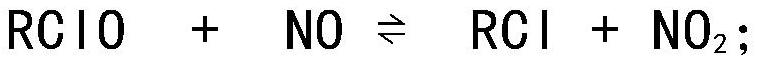

However, those skilled in the art know SO 2 The solubility is not high, which belongs to the medium solubility, while the solubility of NO is very small, and it is impossible to achieve the effect of simultaneous desulfurization and denitrification completely by water dissolution or lye absorption; according to SO 2 Both NO and NO have the characteristics of reduction, when in contact with strong oxidizing agents, SO 2 will be oxidized to SO 3 , SO 3 Very soluble in water to form H 2 SO 4 ; while NO will be oxidized to NO 2、 N 2 o 3 and N 2 o 5 These high-valence nitrogen oxides are easily soluble in water to form HNO 3

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0114] The spray liquid contains 0.2 mass % NaClO + 1 mass % NaOH.

Embodiment 3

[0116] The spray liquid contains 3% by mass NaClO+2% by mass NaOH.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a flue gas desulfurization and denitrification integrated treatment method. The flue gas desulfurization and denitrification integrated treatment method comprises the following steps: (1) pretreatment; (2) primary oxidation; (3) secondary oxidation; (4) hydration reaction; and (5) ion exchange reaction to achieve the purpose of simultaneous desulfurization and denitrification. In the flue gas desulfurization and denitrification integrated treatment process, equipment does not need to be shut down, resin transformation and regeneration are carried out at the same time, the convention of shut-down regeneration is broken through, and one-time investment is saved; in the operation process of the equipment, part of ion exchange resin is regenerated in time, so that the utilization rate of the resin is increased, and the use amount of the resin is greatly reduced.

Description

technical field [0001] The present disclosure relates to the field of flue gas desulfurization and denitrification, and in particular to an integrated treatment method for flue gas desulfurization and denitrification. Background technique [0002] Flue gas refers to the flue gas and dust produced by the combustion of industrial boilers. Among the pollutants contained in flue gas, sulfur dioxide (SO 2 ), nitrogen oxides (NOx) account for a large proportion. And sulfur dioxide (SO 2 ), nitrogen oxides (NOx) are one of the main pollutants that cause air pollution, and effective control of sulfur dioxide and nitrogen oxides in flue gas is an urgent environmental protection issue at present. [0003] Strong base anion exchange resins have strong basic anion exchange groups (-CH 2 N-(CH 3 ) 3 Cl - ), has high affinity and adsorption performance for strongly acidic anions such as sulfate and nitrate, but for SO in the molecular state in flue gas 2 and NOx have no adsorption...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/60B01D53/75B01D53/78B01D53/82B01D53/14B01J47/00

CPCB01D53/60B01D53/75B01D53/78B01D53/82B01D53/1456B01D53/1481B01J47/00B01D2251/10B01D2251/108B01D2251/106B01D2252/103B01D2258/0283Y02A50/20

Inventor 樊振江史磊范瑞华田二飞李龙博杨海岳席海生

Owner 深圳灏权环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com