Method for treating waste gas by using ion exchange resin

An ion exchange resin and resin technology, applied in the field of flue gas desulfurization and denitrification, can solve the problems of insufficient denitrification efficiency, unguaranteed, time-consuming and labor-consuming problems, achieve both oxidation performance and ion exchange performance, and improve utilization rate and turnover efficiency , The effect of high-efficiency desulfurization and denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

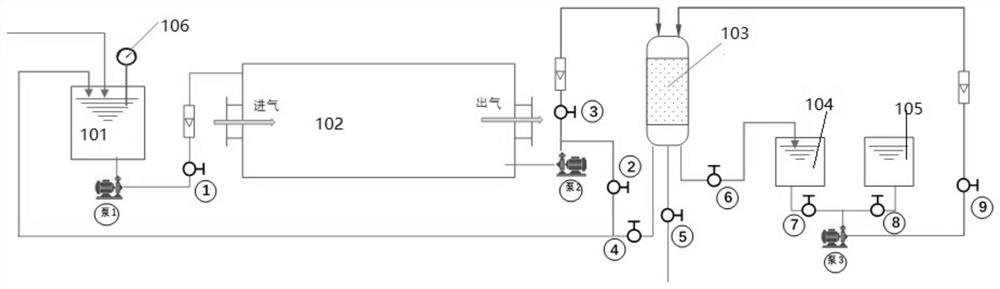

[0125] to handle 10000m 3 / h flue gas unit equipment as an example, the desulfurization and denitrification process is as follows:

[0126] 1. Flue gas pretreatment: flue gas contains SO 2 Concentration 500~2000mg / m 3 , NO concentration is 200~800mg / m 3 , Turn on the induced draft fan, and the flue gas cooled by the flue gas heat exchanger will be 10000m 3 / h flow through the main equipment, the treated flue gas SO 2 and NO emission concentrations are 3 .

[0127] 2. Spray oxidant solution: the composition of spray oxidant solution is 2.5% NaClO+1% NaOH.

[0128] Pre-prepared oxidant solution about 3.5m in the shower pool 3 ;During the operation of the main equipment, turn on the pump 1 and valve 1 to control the flow rate of the drenching liquid to 16m 3 / h (the flow rate is about 2 times the volume of D201SC anion exchange resin, the shower time is about 6 minutes, and the total amount of shower is 1.6m 3 , equivalent to 0.2 times the volume of the resin) after the s...

Embodiment 2

[0135] The composition of spray oxidant solution is 2% Ca(ClO) 2 +1%NaOH, other steps are the same as in Example 1.

Embodiment 3

[0137] The spray oxidant solution consists of: 1.2% NaClO 2 +1%NaOH, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com