Preparation method and application of fiber with high ion exchange volume and high strength

An ion-exchange, high-strength technology, applied in cation exchange materials, fiber treatment, fiber chemical characteristics, etc., can solve the uncontrollable position and quantity of C-C bond breakage, mechanical properties, heat resistance, chemical corrosion resistance, and durability Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

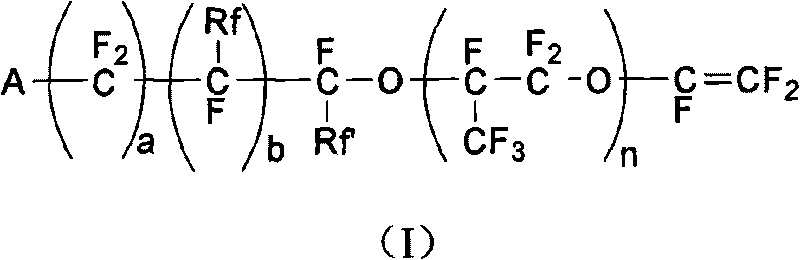

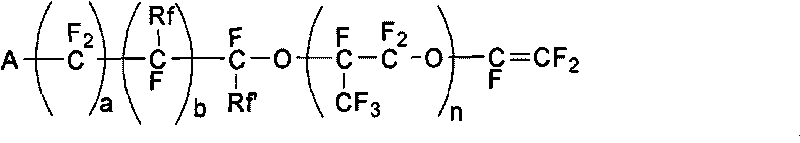

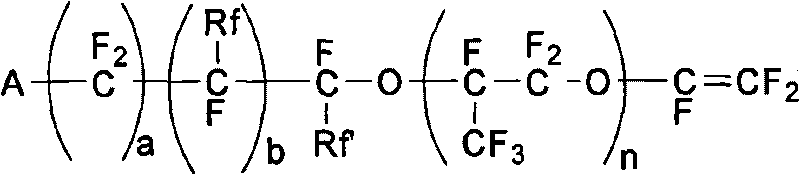

[0075] Embodiment 1: (solution polymerization, fluorocarbon solvent, perfluoroalkyl acyl peroxide initiator)

[0076] Polymerization monomers are selected from tetrafluoroethylene, ethylene, phosphate terminal alkoxy vinyl ether monomer (molecular formula: (CH 3 O) 2 OPCF 2 CF 2 CF 2 OCF=CF 2 (i.e. n=0, Rf'=F, a=2, b=0, A=-PO(OCH 3 ) 2 ) Molecular weight 356g / mol) carry out solution radical copolymerization.

[0077] Clean and fully dry the 10L stainless steel autoclave, vacuumize it, and replace it with nitrogen three times until the oxygen content is controlled below 10ppm, then vacuumize it to -0.1MPa, put 5.8L perfluorocarbon solvent, 560g phosphate terminal alkoxy Alkenyl ether monomer (molecular formula: (CH 3 O) 2 OPCF 2 CF 2 CF 2 OCF=CF 2 Molecular weight 356g / mol) into the reaction kettle, stirred and heated up to 40 ° C, after the system temperature was constant, added 40ml containing 3.94g perfluorobutyryl compound (CF 3 CF 2 CF 2 CO-OO-OCCF 2 CF 2...

Embodiment 2

[0083] Embodiment 2: (solution polymerization, fluorocarbon solvent, perfluoroalkyl acyl peroxide initiator)

[0084] Polymerization monomers are selected from tetrafluoroethylene, ethylene, and phosphate-terminated alkoxy vinyl ether monomers (molecular formula: (PhO) 2 OPCF 2 CF 2 CF 2 OCF=CF 2 (i.e. n=0, Rf'=F, a=2, b=0, A=-PO(OPh) 2 ) Molecular weight 480g / mol) carry out solution radical copolymerization.

[0085] Clean and fully dry the 10L stainless steel autoclave, vacuumize it, and replace it with nitrogen three times until the oxygen content is controlled below 10ppm, then vacuumize it to -0.1MPa, add 5.8L perfluorocarbon solvent, 260g phosphate terminal alkoxy Base vinyl ether monomer (molecular formula: (PhO) 2 OPCF 2 CF 2 CF 2 OCF=CF 2 Molecular weight 480g / mol) into the reaction kettle, stirred and heated up to 40 ° C, after the temperature of the system is constant, add 40ml containing 4.54g perfluorobutyryl compound (CF 3 CF 2 CF 2 CO-OO-OCCF 2 CF ...

Embodiment 3

[0090] Embodiment 3 (suspension polymerization, persulfate is initiator, and water is as dispersion medium)

[0091] Polymerization monomers are selected from tetrafluoroethylene, ethylene, and phosphate terminal alkoxy vinyl ether monomers (molecular formula: CF 2 =CFO-CF 2 CF(CF 3 )O-CF 2 CF 2 PO(OCH 3 ) 2 , (i.e. n=1, Rf'=F, a=1, b=0, A=-PO(OCH 3 ) 2 ) molecular weight 472g / mol) carry out solution radical copolymerization.

[0092] Clean the 10L stainless steel autoclave and vacuumize it, fill it with high-purity nitrogen and replace it three times until the oxygen content is below 10ppm, then vacuumize it to -0.1MPa, and add 4.2g of perfluoropropoxy ammonium carboxylate ( Molecular formula CF 3 CF 3 CF 2 OCFCF 3 CF 2 -OCFCF 3 COONH 4 ) of pure water 6L, 120g phosphate alkyl end group vinyl ether monomer (CF 2 =CFO-CF 2 CF(CF 3 )O-CF 2 CF 2 PO(OCH 3 ) 2 , molecular weight 472g / mol), heat up to 70°C, feed tetrafluoroethylene, ethylene mixed gas (mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com