Synthesis method of high-purity 8-hydroxyquinoline copper

A technology of copper hydroxyquinoline and synthesis method, which is applied in the direction of copper organic compounds, etc., and can solve problems such as unstable quality and low purity of 8-quinolinol copper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of synthetic method of high-purity 8-hydroxyquinoline copper, comprises the following steps:

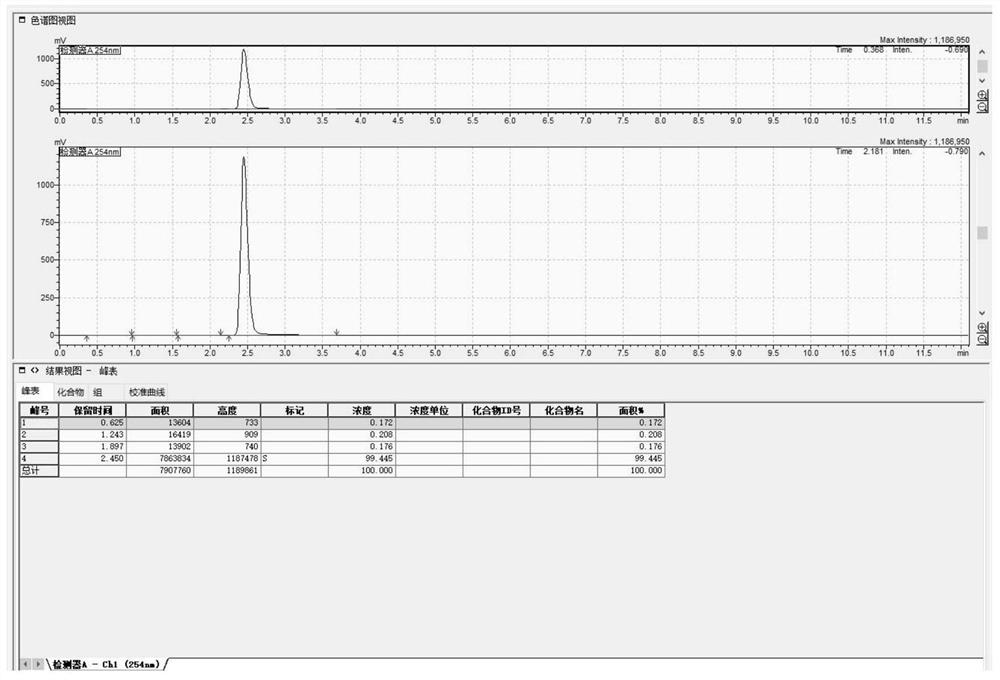

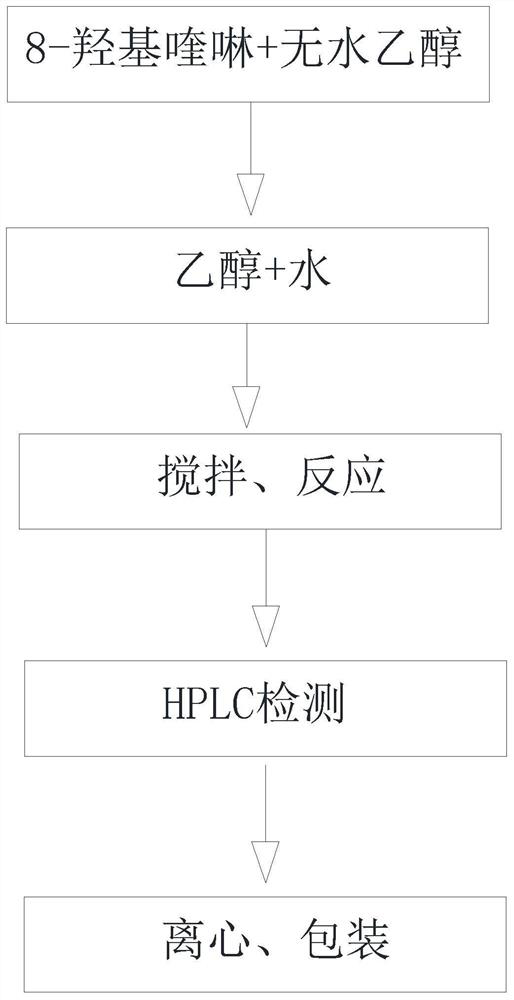

[0025] In a 5-ton reactor, add 790kg of ethanol, 525kg of 8-hydroxyquinoline, the heating rate is 3°C / min, steam is heated to 50°C, stirred and dissolved, the stirring rate is 150r / min, and 462kg of copper sulfate and 2370kg of water are added dropwise. The mixed solution was added dropwise for 1 hour. After the drop was completed, keep it at 50°C for 1 hour, take a sample for HPLC test, cool to 25°C, stir for 2 hours at a stirring rate of 150r / min, and the color of the solid turned green, as figure 1 shown. Centrifuge at a speed of 3000r / min for 15min to obtain 800kg of green powdery solid, and the test indicators meet the enterprise standards and can be bagged. The calculated yield is 99.28%, and the purity is 99.45%. Such as figure 2 Shown is the HPLC test result of this product. Its reaction equation is as follows:

[0026]

Embodiment 2

[0028] A kind of synthetic method of high-purity 8-hydroxyquinoline copper, comprises the following steps:

[0029] In a 5-ton reactor, add 903kg of ethanol, 600kg of 8-hydroxyquinoline, steam heated to 52°C, stir to dissolve, the stirring rate is 200r / min, dropwise add a mixed solution of 528kg of copper sulfate and 2708kg of water, 1h dropwise, After dripping, keep at 52°C for 1.5h, take samples for HPLC test, cool to 25°C, stir for 2.5h, the color of the solid turns green, centrifuge at 3200r / min for 20min, and obtain 914.4kg. Ready to bag. The yield is 99.27%, and the purity is 99.44%.

Embodiment 3

[0031] A kind of synthetic method of high-purity 8-hydroxyquinoline copper, comprises the following steps:

[0032] In a 10-ton reactor, add 1580kg of ethanol and 1050kg of 8-hydroxyquinoline, heat it with steam to 55°C, stir and dissolve at a stirring rate of 200r / min, add dropwise a mixed solution of 924kg of copper sulfate and 4740kg of water, and complete the dropwise addition within 1 hour. After dripping, keep at 55°C for 2h, take samples for HPLC test, cool to 25°C, stir for 3h, the color of the solid turns green, centrifuge at 3500r / min for 30min, and get 1600kg of green powdery solid. The standard can be bagged, the yield is 99.28%, and the purity is 99.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com