Crosslinking type polyether ester amide water reducing agent and preparation method thereof

A technology of polyether ester amide and polyether amide, which is applied in the field of preparation of water reducing agent technology, can solve the problems of slump loss and no obvious improvement in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A cross-linked polyether ester amide water reducer and a preparation method thereof, the steps of the preparation method are:

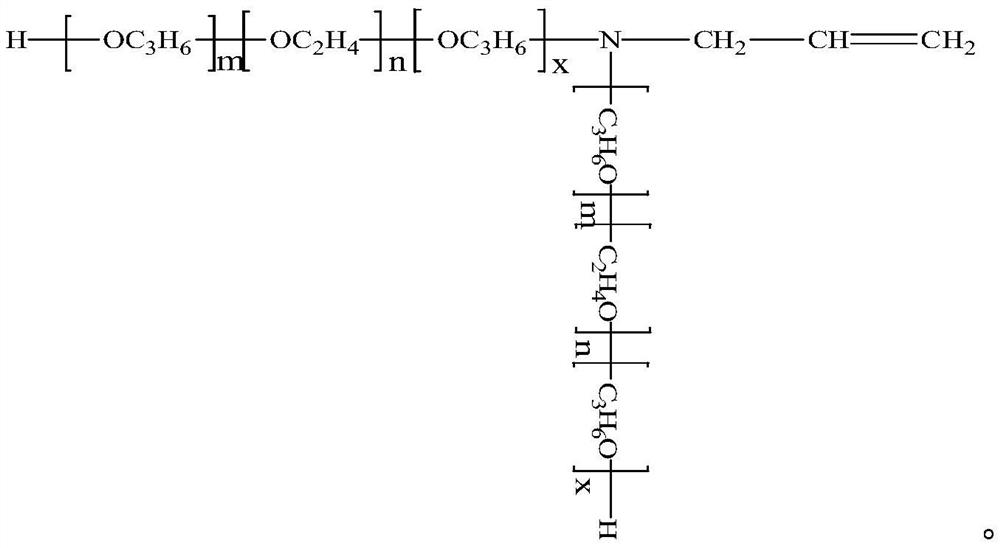

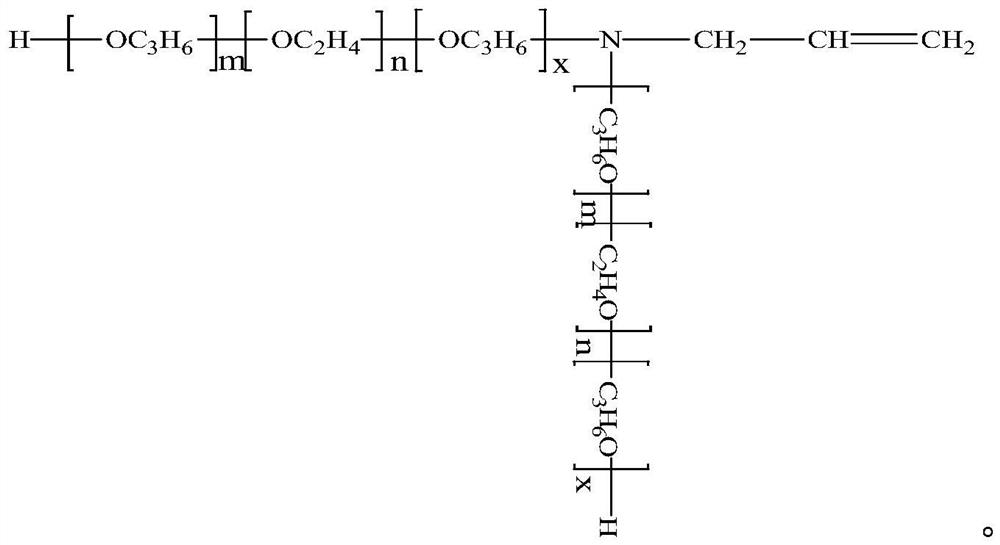

[0026] S1: The initiator allylamine undergoes a nucleophilic substitution reaction with ethylene oxide or propylene oxide to generate an intermediate;

[0027] S2: After the reaction is completed, continue to add ethylene oxide or propylene oxide to the system, and under the action of a basic catalyst, the intermediate and ethylene oxide or propylene oxide continue to undergo a substitution reaction to obtain an unsaturated Polyetheramide;

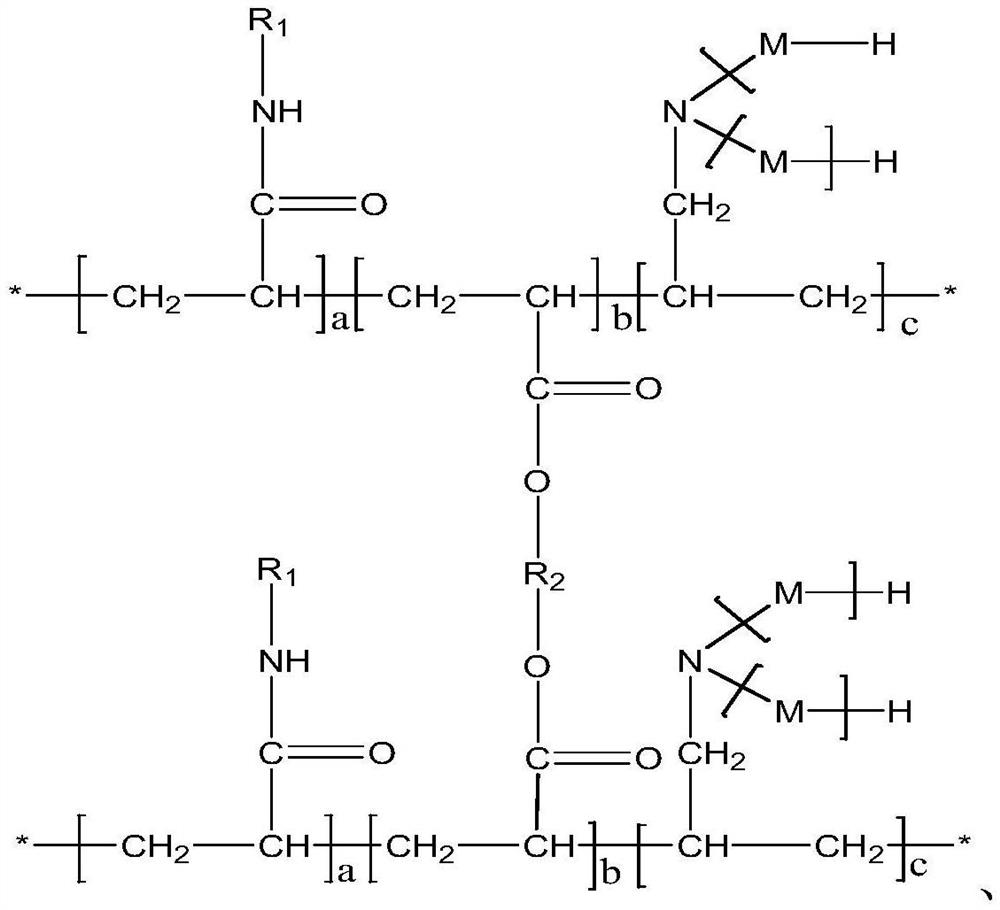

[0028] S3: The unsaturated polyether amide prepared in S2, unsaturated amide, and unsaturated carboxylic acid are combined with small molecules under the action of an initiator and a chain transfer agent, and the temperature is 50°C-60°C;

[0029] S4: Add cross-linking agent and emulsifier after the system is cooled to control the degree of cross-linking, finally adjust the pH value to 6-7, add water to di...

Embodiment 1

[0049] In reactor, add 57g allylamine, the NaOH of 1.2g is catalyst, N2 After replacing the reactor, when the temperature was gradually raised to 90°C, 1.5mol propylene oxide and 10mol ethylene oxide were successively introduced into the reactor, the pressure of the reactor was 0.35MPa, and the reaction temperature was 150°C. After the feeding is completed, stop heating when the pressure drop of the kettle is 0.15MPa, keep the temperature of the kettle at 100°C for aging for 30 minutes, and discharge the material after the pressure drop of the kettle reaches zero, and then obtain polyetheramide. The measured weight-average molecular weight is 1039.1, which is recorded as PA-1.

[0050] Take the prepared PA-1 polyether amide 300g and N-isopropylacrylamide 47.5g, emulsifier sodium lauryl sulfate 11.7g, initiator sodium persulfate 3.2g and add in the reactor, add deionized water 240g , Stir at a constant speed and raise the temperature to 50°C. At the same time, start to add 44g ...

Embodiment 2

[0052] Add 57g allylamine in the reactor, the KOH of 2.8g is as catalyst, N 2 After replacing the reactor, when the temperature was gradually raised to 90°C, 2mol propylene oxide and 12mol ethylene oxide were introduced into the reactor successively, the pressure of the reactor was 0.35MPa, and the reaction temperature was 150°C. After the feeding is completed, stop heating when the pressure drop of the kettle is 0.15 MPa, keep the temperature of the kettle at 100°C for aging for 30 minutes, and discharge the material after the pressure drop of the kettle reaches zero, and then obtain polyetheramide. The measured weight-average molecular weight is 1247.3, recorded for PA-2.

[0053] Get 350g of PA-2 polyetheramide and 86g of N-isopropylacrylamide, 13g of sodium laureth sulfate, and 5.9g of initiator potassium persulfate into the reactor, add 240g of deionized water, Stir at a constant speed and raise the temperature to 50°C-60°C. At the same time, start to add 62g of methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com