High-hardness polishable acrylate two-component structural adhesive for repairing and preparation method of high-hardness polishable acrylic acid two-component structural adhesive

A two-component, structural adhesive technology, applied in the direction of acrylonitrile butadiene styrene polymer adhesives, adhesives, conjugated diene adhesives, etc., can solve the problems of poor hardness and fluidity, unfavorable wear parts repair and Grinding, poor bonding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

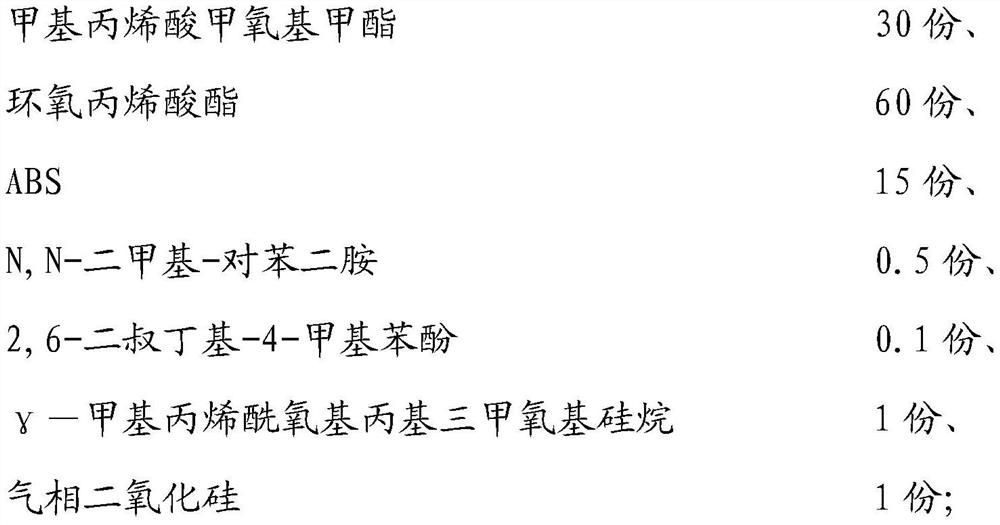

[0028] A component weighs raw materials according to the following parts by mass

[0029]

[0030] (1) Stir methoxymethyl methacrylate and prepolymer with 600rpm / min in a stirrer for 30min;

[0031] (2) Put the ABS into the mixer slowly, and stir at a high speed of 800rpm / min for 2 hours until it is completely dissolved;

[0032] (3) Add γ-methacryloxypropyltrimethoxysilane and 2,6-di-tert-butyl-4-methylphenol, and stir at 600rpm / min for 30min;

[0033] (4) Cool down to below 35°C;

[0034] (5) Add N,N-dimethyl-p-phenylenediamine, control the temperature below 35°C and stir at 600rpm / min;

[0035] (6) Add fumed silica at 600rpm / min and stir for 30min to obtain component A

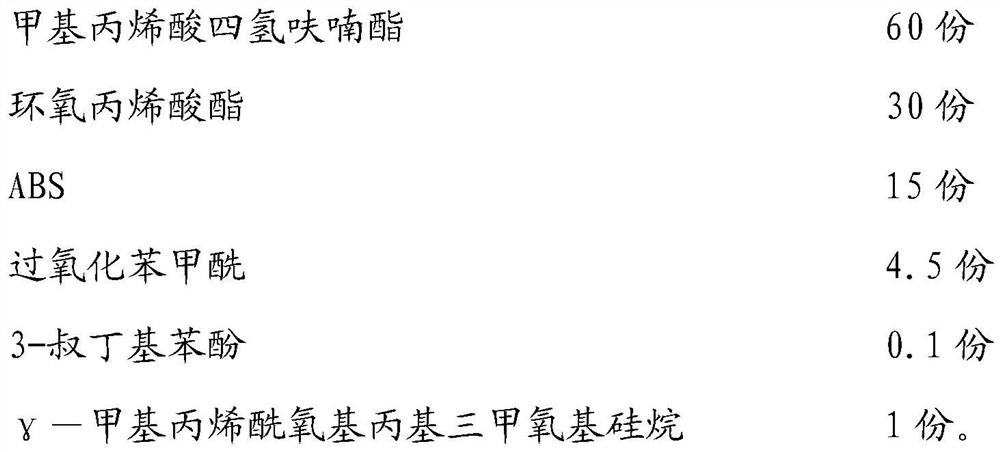

[0036] B component weighs raw materials according to the following parts by mass

[0037]

[0038] (1) Methyl methacrylate and prepolymer were stirred at 600rpm / min in a stirrer for 30min;

[0039] (2) Slowly put the elastomer into the mixer, and stir at a high speed of 800rpm / min for 2h until it...

Embodiment 2

[0043] Embodiment 2 of the present invention provides a methacrylate-based structural adhesive, and its specific implementation method is the same as that of Embodiment 1, except that epoxy acrylate is replaced by polyurethane acrylate.

Embodiment 3

[0045] Embodiment 3 of the present invention provides a methacrylate structural adhesive, and its specific implementation method is the same as that of Embodiment 1, except that ABS is replaced by chlorosulfonated polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com