Method for patterning chinlon fabric

A patterning, fabric technology, applied in the textile field, which can solve the problem of unexplored production of decorative surface patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for patterning nylon fabrics, comprising the steps of:

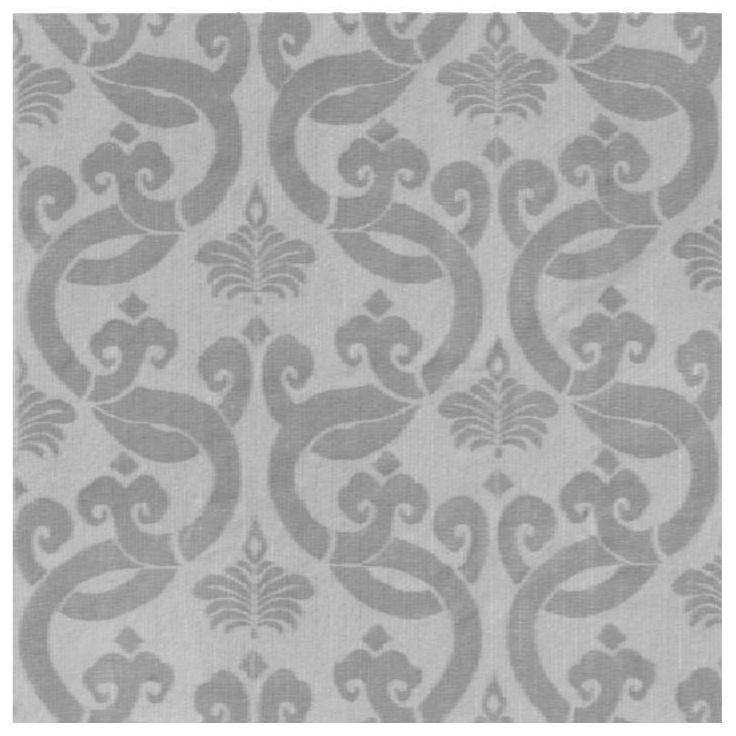

[0069] (1) Laser pretreatment

[0070] according to figure 1 The pattern, using JG-13090 laser machine (Wuhan, Hubei, Jinyun Laser Co., Ltd.), using the photothermal characteristics of infrared laser to carry out full laser surface irradiation treatment on nylon fabric (10cm×10cm), set the laser machine at a fixed focal length The diameter of the spot is 0.5mm, the laser power is 12w, the laser scanning speed is 300mm / s, the scanning distance is 0.2mm, and the number of scanning is 1 time to obtain the laser pretreated nylon fabric;

[0071] (2) Dyeing

[0072] Use pomegranate peel dye to directly dye the nylon fabric after laser pretreatment, the dye dosage is 2% o.w.f, the bath ratio is 1: 30, the pH value of the dyeing bath is 3 (adjusted by citric acid), the dyeing is started at room temperature, and the heating rate is 1°C / min rises to a dyeing temperature of 98°C, heat-preserves and dyes for 60m...

Embodiment 2

[0074] Adjust the laser power in Example 1 to 4w, 8w, 12w, 16w, 20w, and the dyestuff consumption is 3% o.w.f. Other laser pretreatment and dyeing conditions are consistent with Example 1 to obtain the nylon fabric of laser pretreatment and pomegranate peel dyeing .

Embodiment 3

[0097] The dosage of the dye in Example 1 was adjusted to 1, 3, 4% o.w.f, and other laser pretreatment and dyeing conditions were kept the same as in Example 1 to obtain a nylon fabric with laser pretreatment and pomegranate peel dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com