Expansion type fireproof insertion strip, manufacturing method thereof and fireproof door and window

It is a technology of cuttings production and expansion, which is applied in fire doors, door/window applications, windows/doors, etc. It can solve the problems of accumulating moisture, increasing the production and maintenance costs of fire-resistant doors and windows, and the inability to realize mass production of fire-resistant cuttings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

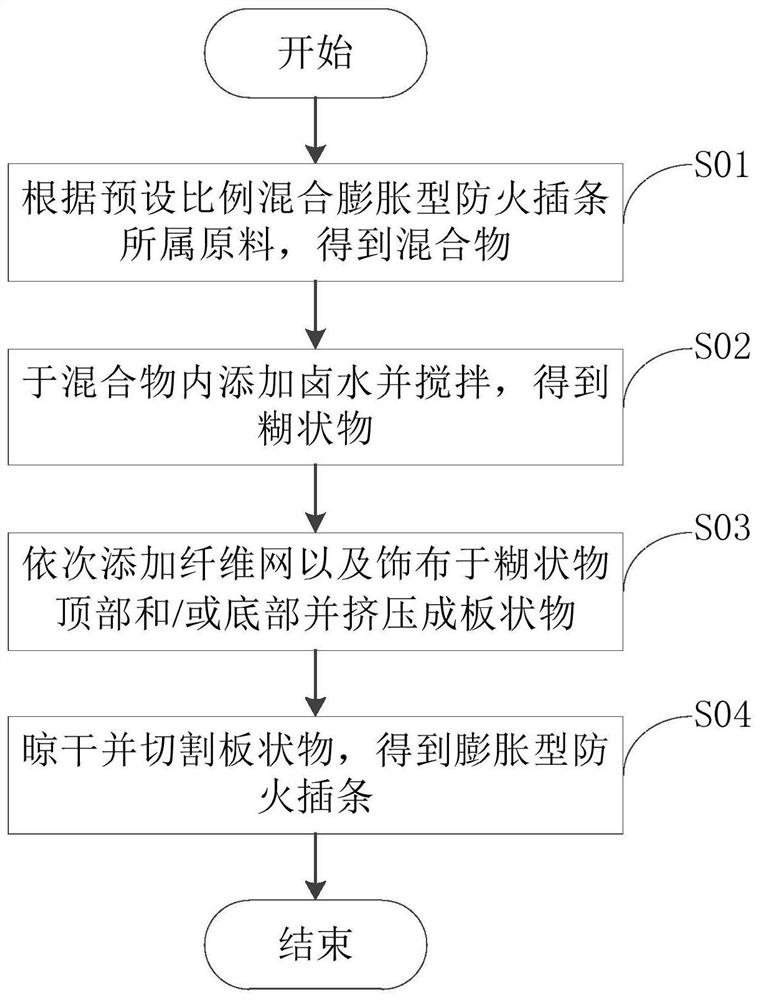

[0039] In view of this, if figure 1 As shown, the present invention provides a method for making inflatable fireproof inserts, comprising the following steps:

[0040] S01: Mix the raw materials of the intumescent fireproof cuttings according to the preset weight ratio to obtain the mixture;

[0041] The above-mentioned mixture forms the base material of the above-mentioned intumescent fireproof inserts through processes such as stirring, extruding, and cutting. It should be noted here that, according to the composition difference of the mixture, the above-mentioned base material can be set as intumescent type or non-intumescent type according to needs.

[0042] S02: adding brine into the mixture and stirring to obtain a paste;

[0043] Among them, brine is a mixture of magnesium chloride, magnesium sulfate and sodium chloride, which is usually used for protein coagulation. The above-mentioned brine is added to the above-mentioned mixture, followed by stirring to solidify. ...

Embodiment 2

[0053] On the basis of Example 1, in a preferred implementation manner, the above-mentioned intumescent fireproof inserts are made into a structure in which the base material intumescent trim does not inflate. Specifically, the intumescent fireproof cuttings consist of 101 parts of expansive material, 100 parts of magnesium oxide, 1 part of additive, 100 parts of sawdust, 50 parts of water, 0.2 part of fiber net and 15 parts of decorative cloth.

[0054] Wherein the above-mentioned expanded material includes vermiculite and / or expanded graphite, and the mass ratio of vermiculite to expanded graphite is 100:1. The above-mentioned decorative cloth adopts non-woven fabric. The preparation process of the above-mentioned intumescent fireproof cuttings is as in Example 1, and will not be repeated here.

Embodiment 3

[0056] On the basis of Example 1, in a preferred implementation manner, the above-mentioned intumescent fireproof insert is made into a structure in which the base material does not inflate the decorative cloth. Specifically, the intumescent fireproof cuttings consist of 100 parts of magnesium oxide, 1 part of additive, 100 parts of sawdust, 50 parts of water, 0.2 part of fiber net and 20 parts of decorative cloth.

[0057] Compared with the lack of expansion material in the above-mentioned base material in the second embodiment, the decoration cloth is preferably made of a material with a high expansion rate (high temperature expansion cloth). The above-mentioned high expansion ratio has a relatively high coefficient of thermal expansion, including but not limited to the use of polyethylene and the like. The preparation process of the above-mentioned intumescent fireproof cuttings is as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com