Multi-channel flexible array type sensor, manufacturing method thereof and method for monitoring stress of curved-surface metal piece

A flexible sensor and flexible array technology, applied in the measurement, instrument, measuring device and other directions of applying the property force of piezoresistive materials, can solve the problems of high failure rate of a single sensor, limited monitoring range, electrostatic interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

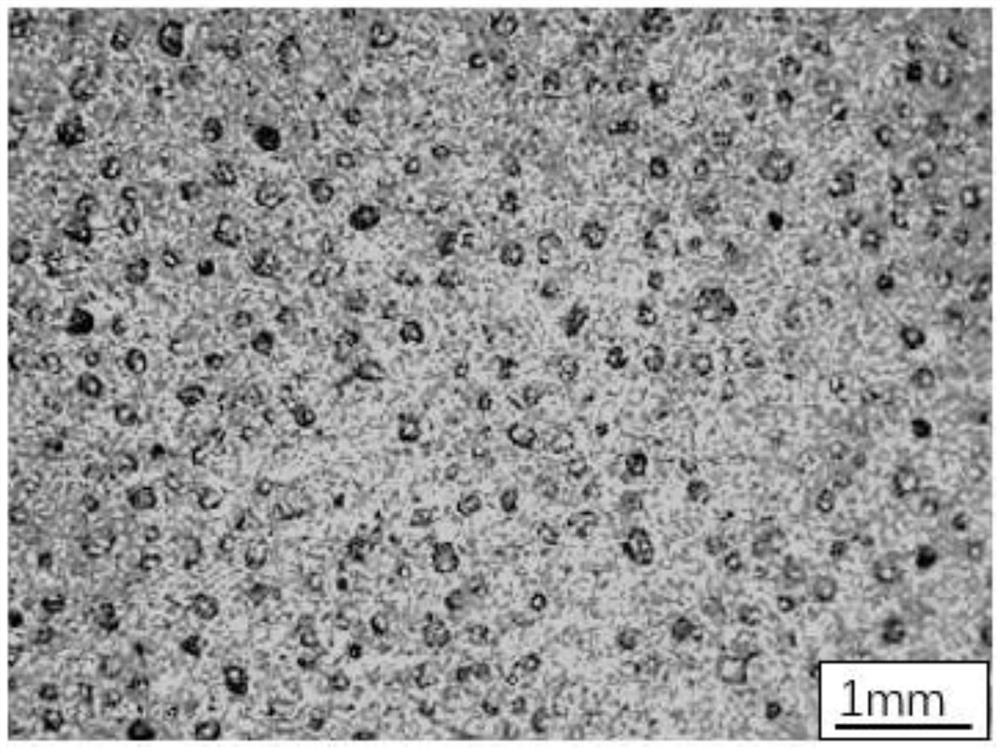

[0049] (1) Prepare the required graphene by thermal expansion-ultrasonic combined method, specifically: after thermal expansion of 0.5 g of expandable graphite at a thermal expansion temperature of 700° C., use acetone as a solvent for ultrasonic oscillation for 3 hours, remove acetone, and obtain graphene;

[0050] (2) With normal hexane as solvent, the obtained graphene and basic component PDMS are mixed uniformly by solvent resonance method to obtain mixed reagent A; wherein, graphene accounts for the best 5% mass fraction of mixed reagent A; solvent resonance method In order to adopt an ultrasonic instrument to oscillate, the oscillation frequency is 40kHz, the temperature is controlled at ≤ 40°C, and the ultrasonic time is 30min.

[0051] (3) According to the mass ratio, the basic component PDMS:NaCl=10g:12g, the NaCl and the mixed reagent A were mixed uniformly by mechanical mixing method, and 3g of n-hexane solvent was added to adjust the fluidity to obtain the mixed rea...

Embodiment 2

[0061] (1) The required graphene is prepared by thermal expansion-ultrasonic combined method. The specific preparation method is to thermally expand 0.5 g of expandable graphite at a thermal expansion temperature of 700 ° C. After thermal expansion, use acetone as a solvent and ultrasonically oscillate for 2 hours to remove acetone to obtain Graphene;

[0062] (2) With normal hexane as solvent, the obtained graphene and basic component PDMS are mixed uniformly by solvent resonance method to obtain mixed reagent A; wherein, graphene accounts for the best 5% mass fraction of mixed reagent A; solvent resonance method In order to adopt an ultrasonic instrument to oscillate, the oscillation frequency is 40kHz, the temperature is controlled at ≤40°C, and the ultrasonic time is 40min.

[0063] (3) According to the mass ratio, the basic component PDMS: NaCl = 10g: 12g is mixed uniformly with NaCl and mixed reagent A by mechanical mixing method, and 3.5g of n-hexane solution is added t...

Embodiment 3

[0071] (1) The required graphene is prepared by thermal expansion-ultrasonic combined method; the specific preparation method is to thermally expand 0.5g of expandable graphite at a thermal expansion temperature of 700°C. After thermal expansion, use acetone as a solvent and ultrasonically oscillate for 2 hours to remove acetone to obtain Graphene;

[0072] (2) Using n-hexane as a solvent, the prepared graphene and the basic component PDMS are mixed uniformly by a solvent resonance method to obtain a mixed reagent A; wherein, graphene accounts for a mass fraction of the mixed reagent A of 4%;

[0073] (3) According to the mass ratio, the basic component PDMS:NaCl=2:1 mass ratio, the mixed reagent A and 5gNaCl are mixed uniformly by mechanical mixing, and 3g of n-hexane is added to adjust the dilution. The NaCl used is made by low-temperature planetary ball milling method ; The temperature is -20°C, the mass ratio of the ball to the material is, the grinding ball: NaCl=20:1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com