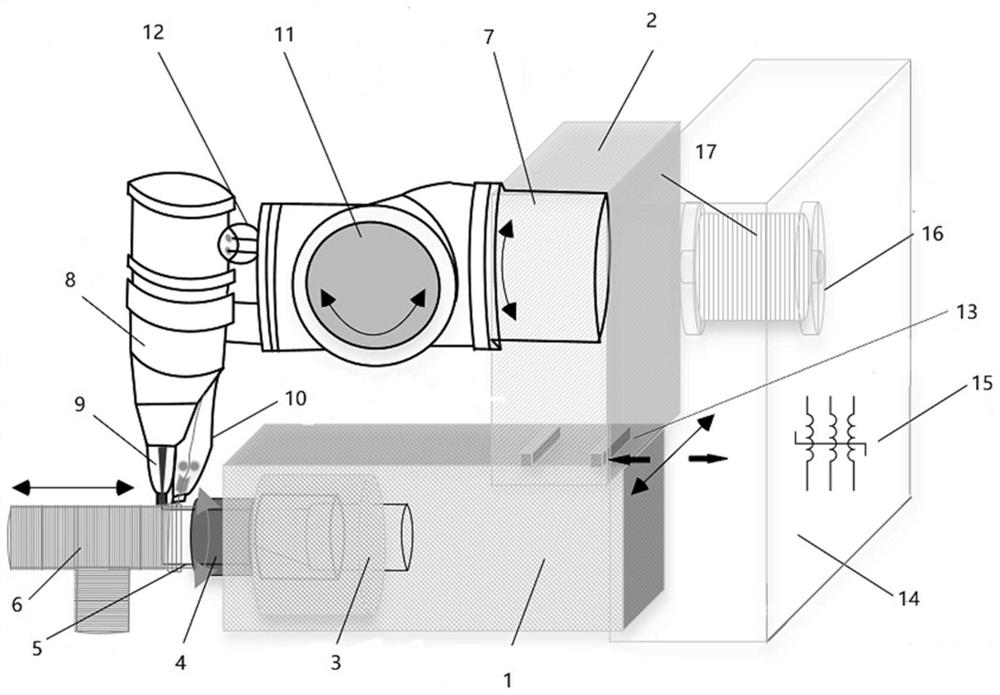

Metal additive manufacturing system and method

A metal additive and manufacturing system technology, applied in the direction of manufacturing tools, metal processing equipment, process efficiency improvement, etc., can solve the problems of material limitation, high manufacturing cost, and the inability to cool down the molten forming area quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

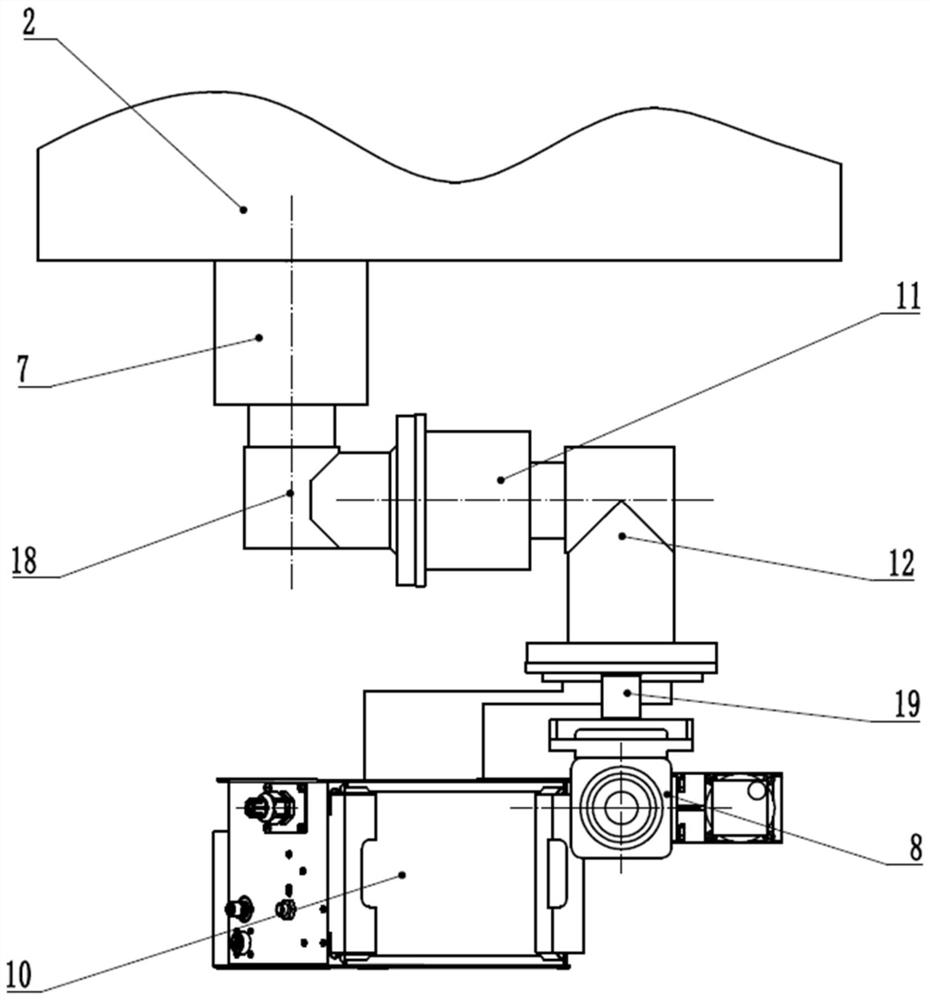

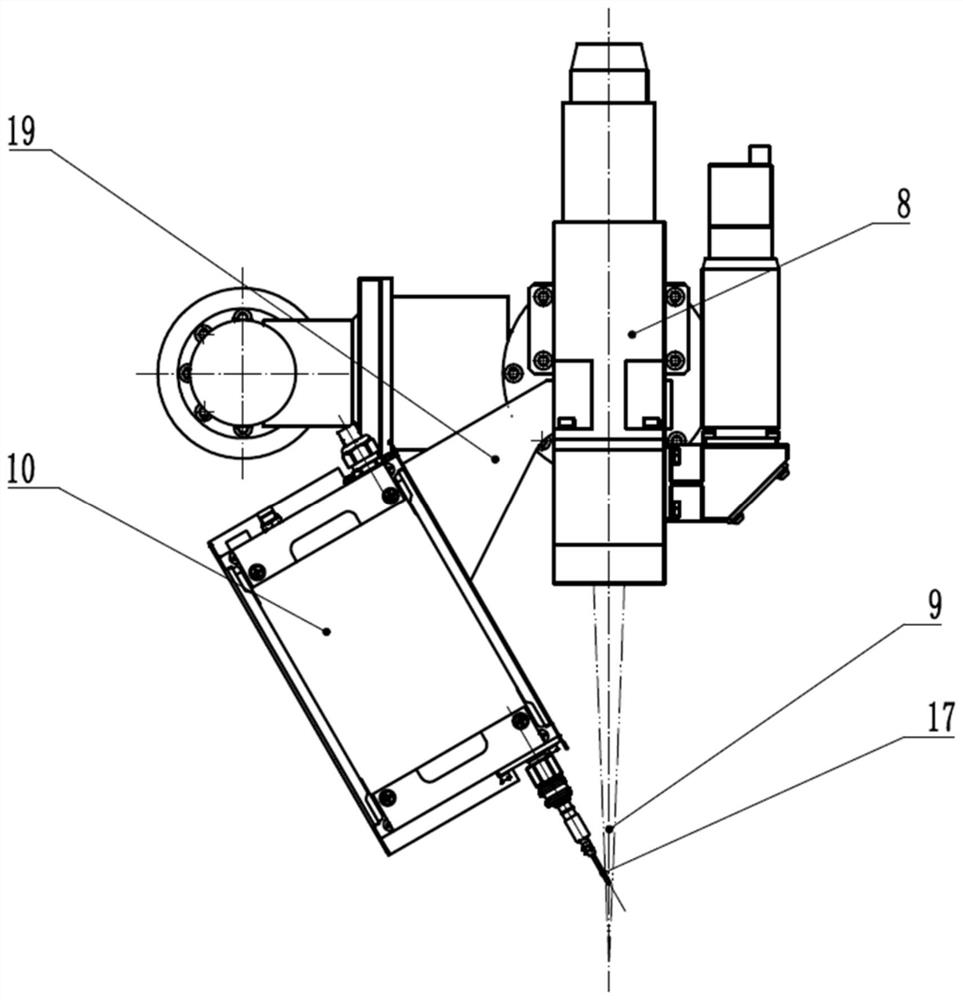

[0046] The workpiece support shaft is prepared by a prefabricated mold. The device of this application is mainly used for parts such as rotary bodies, including the following steps:

[0047] S1, according to the length and thickness of the workpiece to be formed, set the forming displacement distance of the wire feeding forming device; according to the inner cavity diameter of the workpiece to be formed, select a workpiece support shaft with a suitable diameter;

[0048] S2. Adjust the initial position of the high-energy beam and the wire-feeding head to the starting surface of the workpiece support shaft through the rotary manipulator, start the forming heat source and the rotary drive motor, and the high-energy beam of the forming heat source will melt and fix the wire bundle passing through the wire-feeding head to the workpiece support shaft Above, the control system controls the rotary manipulator to start moving, so that the high-energy beam and the wire feeding head move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com