A self-removing slag type bearing grinding process and grinding device

A grinding process and bearing technology, which is applied in the field of bearing processing, can solve the problems affecting the forming size and roundness of bearing steel balls, the bearing steel balls cannot be repaired, and the grinding residue cannot be cleaned, so as to improve the service life, avoid quality problems, and improve wear resistance The effect of sex and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

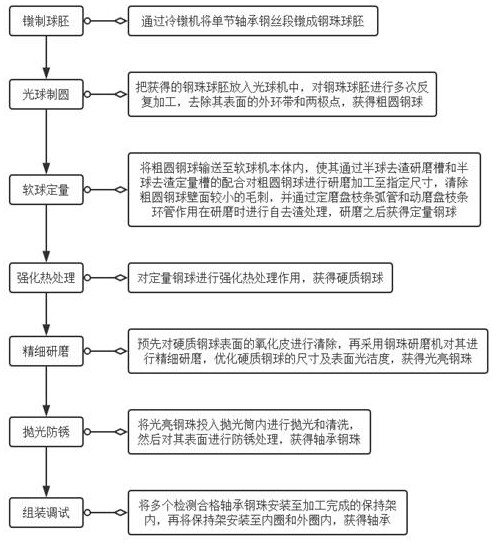

[0052] see Figure 1-10 , a self-removing slag type bearing grinding process, comprising the following steps:

[0053] S1. Upsetting ball blanks: Upsetting single-section bearing steel wire segments into steel ball blanks through a cold heading machine;

[0054] S2. Light ball making circle: Put the obtained steel ball blank into the light ball machine, and repeatedly process the steel ball blank, remove the outer ring belt and two poles on the surface, and obtain a thick round steel ball;

[0055] S3. Quantification of soft balls: transport the thick round steel balls into the soft ball machine body 1, and make them grind the thick round steel balls to the specified size through the cooperation of the hemispherical slag removal grinding tank 201 and the hemispherical slag removal quantitative tank 301, Remove the small burrs on the wall surface of the thick round steel ball, and perform self-removing slag treatment through the action of the fixed grinding disc branch arc tub...

Embodiment 2

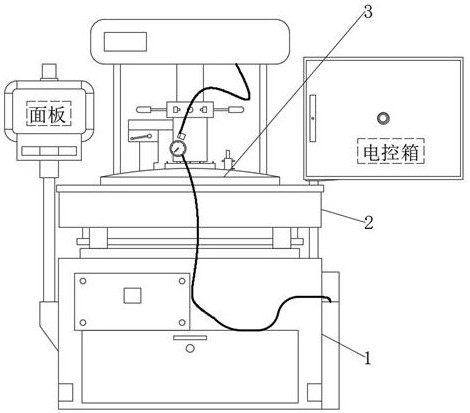

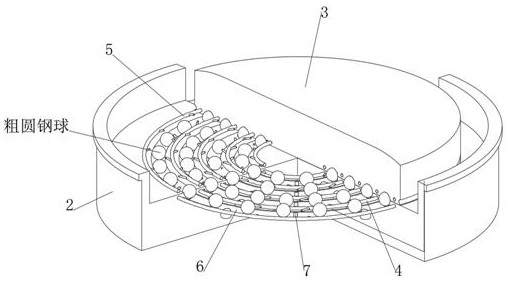

[0063] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 2-4 , a self-removing slag-type bearing grinding device, comprising a soft ball machine body 1, a fixed grinding disc 2 for guiding materials and a quantitative movable grinding disc 3 positioned on the upper side of the fixed grinding disc 2 are installed on the main body 1 of the soft ball machine, and the upper end of the fixed grinding disc 2 is opened There is a hemispherical slag-removing grinding tank 201, and the fixed grinding disc 2 of the guide material is fixedly connected with a fixed grinding disc branch arc tube 4 matching with the hemispherical slag-removing grinding tank 201, and the outer end of the fixed grinding disc branch ar...

Embodiment 3

[0066] see Figure 1-10 , wherein the same or corresponding components as those in Embodiment 2 use the corresponding reference numerals as in Embodiment 2, and for the sake of simplicity, only the differences from Embodiment 2 are described below. The difference between this embodiment 3 and embodiment 2 is: please refer to Figure 5 A residual liquid guide groove located at the lower side of the hemispherical slag removal grinding groove 201 is opened in the fixed grinding table 2 of the material guide, and a residual liquid concentration chamber 202 is provided on the lower side of the fixed grinding table 2, and the lower inner wall of the residual liquid guide groove is fixedly connected with a drainage arc tube 6 , the drainage arc tube 6 is fixedly connected with a plurality of drainage branch pipes 601 connected with it, and the lower end of the drainage branch pipe 601 extends into the raffinate concentration chamber 202 and is connected with the raffinate concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com