Anti-crack anti-seepage self-repairing C35 mass concrete

A large-volume concrete and self-repairing technology, applied in the field of concrete, can solve the problems of concrete structure damage, difficulty in crack resistance, high mud (powder) content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

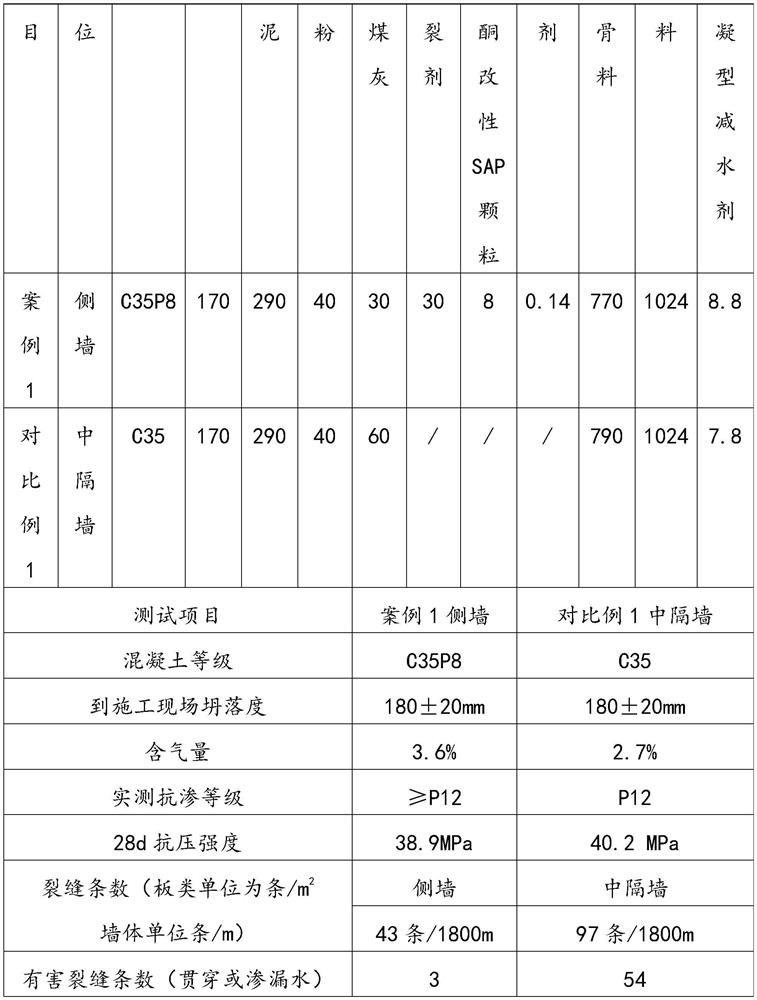

[0025] A kind of anti-crack and anti-seepage self-repairing C35 large-volume concrete, the mass parts of each component are as follows:

[0026] 200-290 parts of cement, 0-50 parts of mineral powder, 30-100 parts of fly ash, 0.1-0.3 parts of air-entraining agent, 700-850 parts of fine aggregate, 1000-1100 parts of coarse aggregate, 155-175 parts of water , 4-10 parts of retarding water reducer, 25-35 parts of anti-cracking agent, 5-10 parts of silicone modified SAP particles.

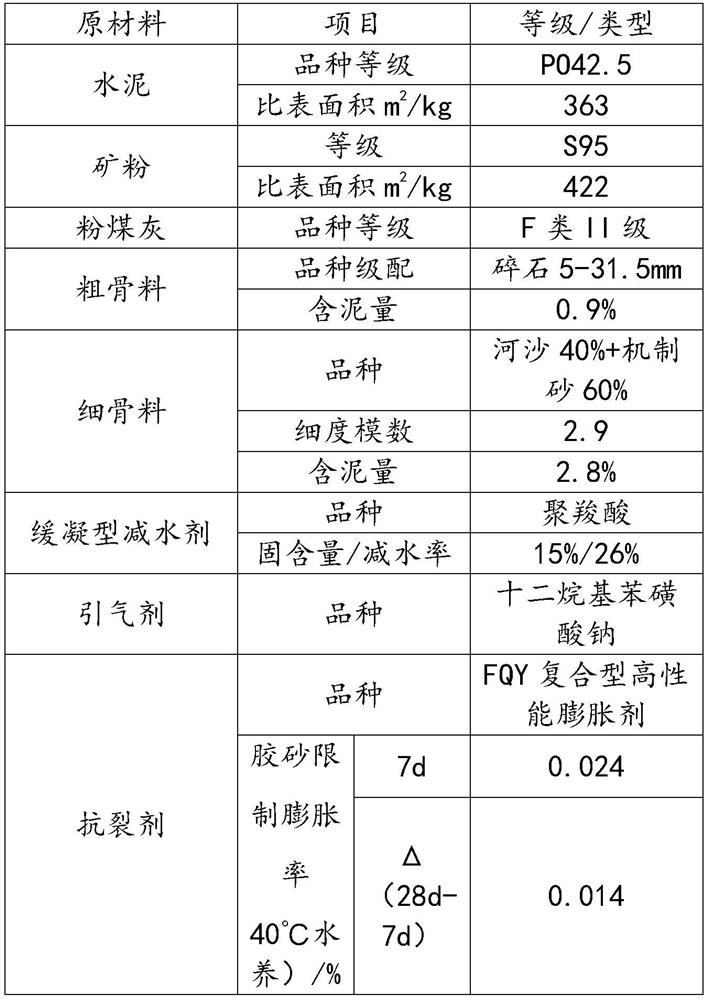

[0027] Among them, the grade of cement is ordinary portland cement above 42.5; the mineral powder is granulated blast furnace slag powder above S95; the fly ash is the fly ash of class F power plant above grade II; Graded crushed stone with a mud content of less than or equal to 1.0%; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com