Method for carrying out electrified repair on horizontal aluminum bus

A live repair and aluminum bus bar technology, applied in the field of welding materials, can solve the problems of long welding preheating time, high manufacturing cost of welding molds, poor wear resistance of welding metal, etc., and achieve good weld quality, increased heat release, Improve the effect of slagging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

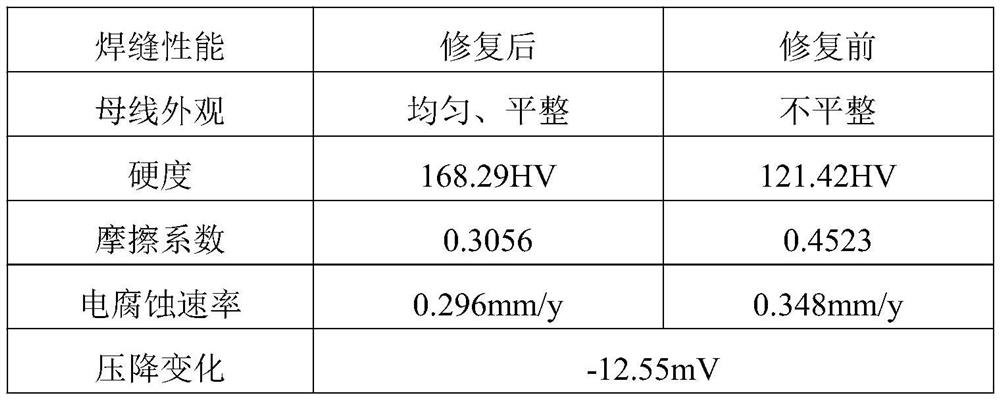

Embodiment 1

[0035] Step S1: to find the damaged area of the horizontal aluminum bus, and the removal of damaged area facing the vertical from the horizontal top aluminum bus, to be welded is formed weld; weld to be welded in dimensions of length 55mm, width 24mm, depth of 23cm H;

[0036] Step S2: brushing a layer of saturated solution of lithium chloride to be welded in said weld surface;

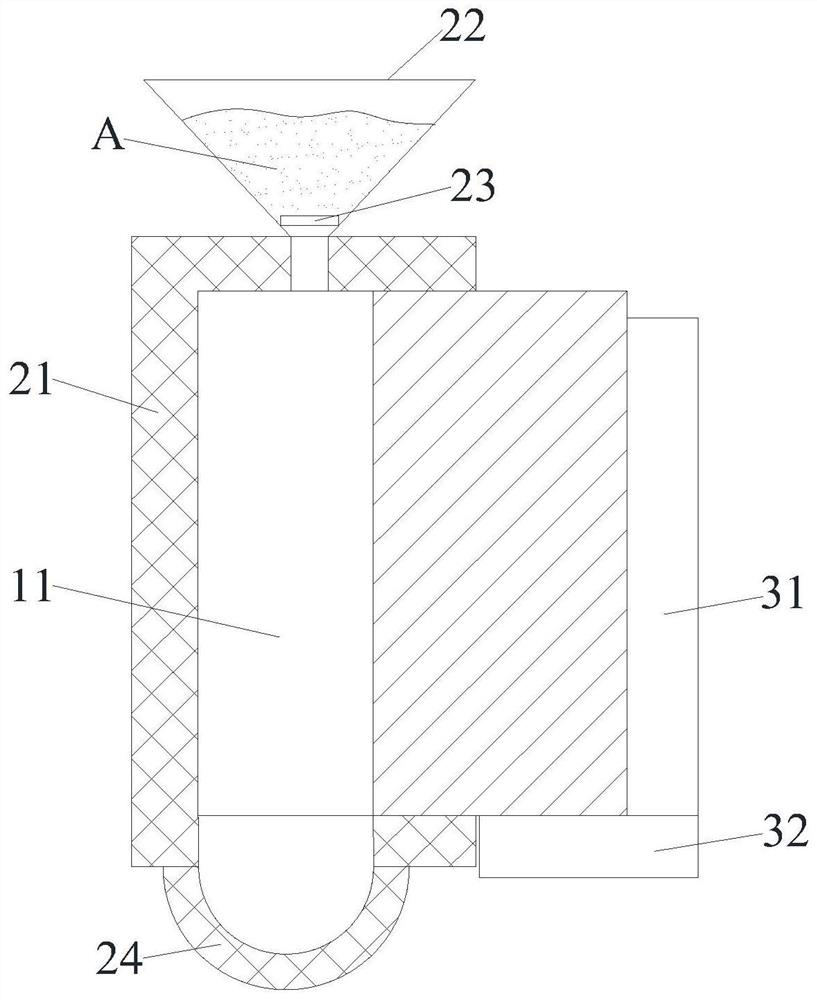

[0037] Step S3: the die mount package sealed weld to be welded, the packaging mold 3 and side plates form characters " 'shape, which is downwardly convex lower plate hemispherical center position; Then, in the and a bottom surface to be welded the weld heat resistant steel plate back surface of a support, the support surface of the heat resistant steel plate of high temperature paint brush;

[0038] Step S4: the charging orifice below the die block with the flap, according to the formula m = 0.75H, m units of kg, H cm & lt units, weighed 17.25kg of aluminum bus flux charge charged mold; wherein aluminum...

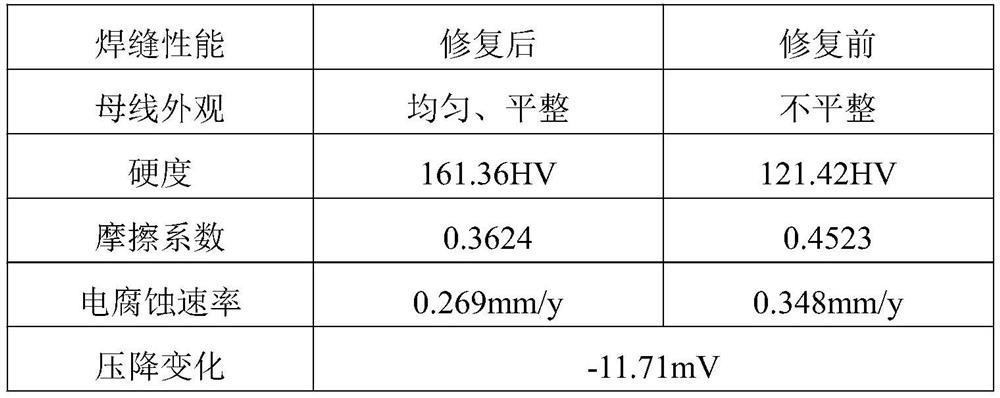

Embodiment 2

[0045] Step S1: Find the damage zone of the horizontal aluminum bus bar, and vertically remove the damage zone in the top of the horizontal aluminum busbar, forming the weld weld port; the size of the medium to be welded is 55 cm, width 24cm, deep H is 14cm;

[0046] Step S2: A layer of saturated a lithium chlorinated solution is applied to the surface of the preparation of the weld weld.

[0047] Step S3: The mounting package will be sealed to be welded, and the package mold is composed of three side plates and is a Chinese character "匚" shape, and the central position of the lower side plate is protruded downward; it followed The bottom surface and the back surface of the welding port are provided to support the heat-resistant steel plate, support the surface brush of the heat-resistant steel plate;

[0048] Step S4: Block the small hole under the charge mold, press the formula M = 0.75 h, M unit is kg, H unit is cm, weigh 10.55 kg of aluminum bus bar flux is loaded in the charg...

Embodiment 3

[0055] Step S1: Find the damage zone of the horizontal aluminum bus bar, and vertically remove the damage zone from the top of the horizontal aluminum busbar to form the welded welding. The size of the medium to be welded is 55cm long, the width is 24 cm, and the deep H is 14.3cm;

[0056] Step S2: A layer of saturated a lithium chlorinated solution is applied to the surface of the preparation of the weld weld.

[0057] Step S3: The mounting package will be sealed to be welded, and the package mold is composed of three side plates and is a Chinese character "匚" shape, and the central position of the lower side plate is protruded downward; it followed The bottom surface and the back surface of the welding port are provided to support the heat-resistant steel plate, support the surface brush of the heat-resistant steel plate;

[0058] Step S4: Blocking the small hole under the charge mold, pressing the formula M = 0.75 h, M unit is kg, H unit is cm, weighs 10.725 kg of aluminum bus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com