Preparation method of ultra-thick heat-conducting graphene film

A technology of thermally conductive graphite and graphene film, applied in graphene, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of low production efficiency, long time consumption, etc., and achieve the effect of enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

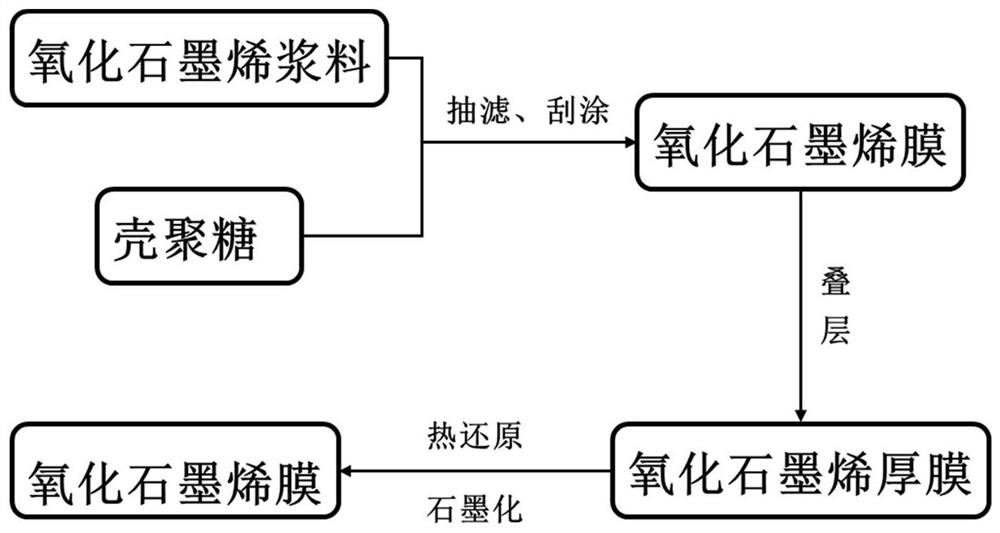

[0031] Such as figure 1 As shown, the invention provides a kind of preparation method of ultra-thick heat-conducting graphene membrane, comprises the following steps:

[0032] 1) adding chitosan to graphene oxide water slurry with a mass concentration of 1 to 6wt.%, wherein the solid content of chitosan is 0.2 to 2wt.%, to obtain a modified graphene oxide slurry;

[0033] 2) Punching out conical protrusions on the substrate, assembling the modified graphene oxide slurry on the substrate to form a graphene oxide film with a thickness of 10-300 microns and spikes;

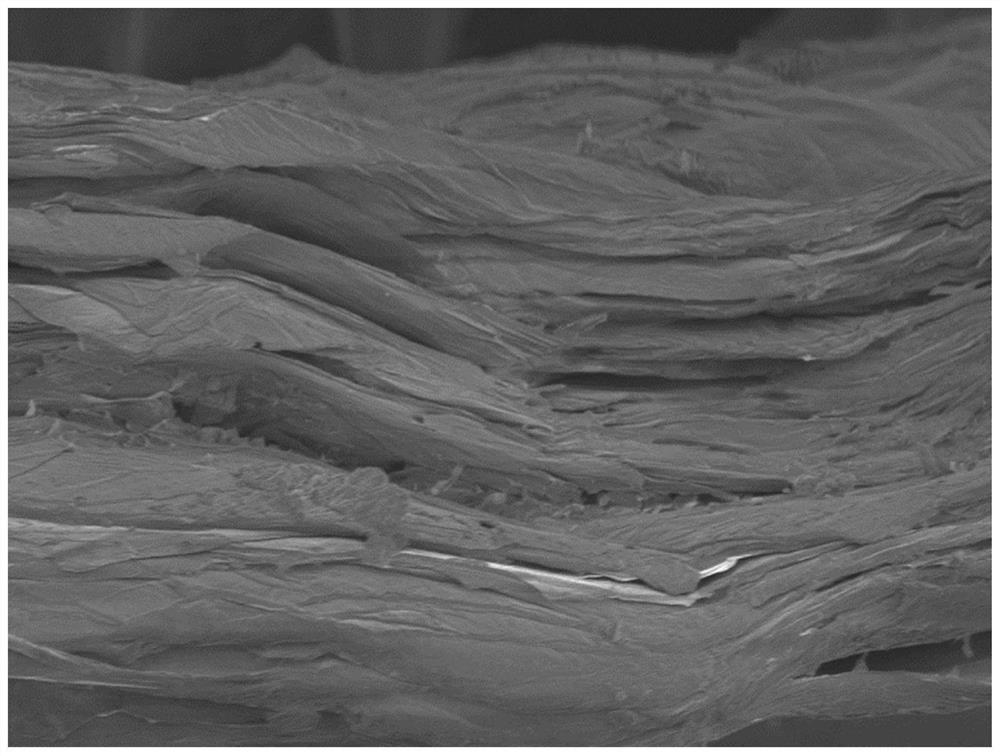

[0034] 3) Several layers of graphene oxide films are stacked and pressed, and each layer of graphene oxide films is formed under the interlocking action of polymer additives and "spikes" to form a 300-6000 micron graphene oxide sheet ( figure 2 ), heating up to 1200°C at a rate of 1°C / min to remove non-carbon atoms;

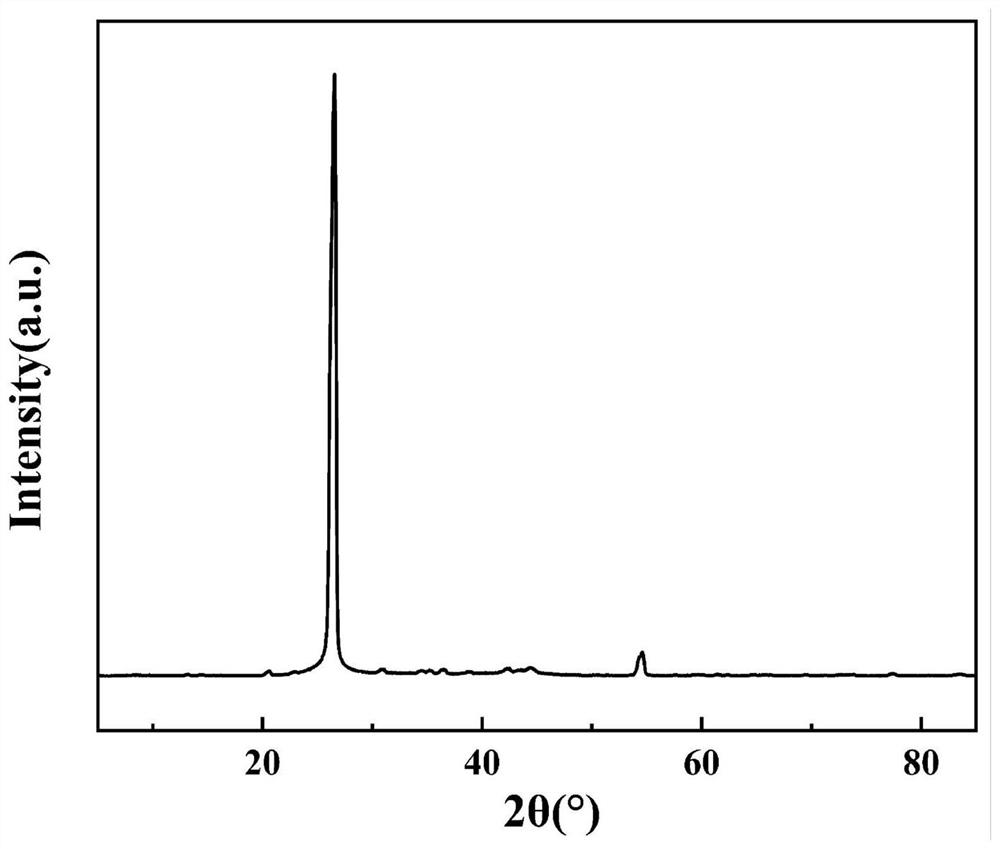

[0035] 4) The heat-reduced graphene sheet is heated to 2200-3100° C. at a rate of 5° C. / min under...

Embodiment 1

[0037] 1) With an average sheet diameter of 2 microns and a graphene oxide slurry with a mass concentration of 1.0wt.% as a precursor, add chitosan with a solid content of 1wt.% to the graphene oxide slurry to form a viscous slurry.

[0038] 2) Punch out conical protrusions on the polytetrafluoroethylene substrate, and the height of the protrusions is about 5 microns. Sizing and coating chitosan-modified graphene oxide slurry on a patterned polytetrafluoroethylene substrate to form a film with a film thickness of 50 microns. When the graphene oxide film is lifted off, there are also obvious " Spike".

[0039] 3) Laminate 6 layers of graphene oxide, pressurize to 5Mp, heat up to 60°C, hold heat and hold pressure for 1 hour to form a tightly bonded multilayer graphene oxide film with a thickness of 300 microns.

[0040] 4) Cut the graphene oxide thick film into a square of 100×100mm, put it into a graphite mold, and then raise the temperature to 1200°C at a rate of 1°C / min. Af...

Embodiment 2

[0044] 1) With the average sheet diameter being 0.5 micron, the graphene oxide slurry that the mass concentration is 1.5wt.% is a precursor, and adding solid content to the graphene oxide slurry is 2wt.% chitosan to form a viscous slurry.

[0045] 2) Punch out conical protrusions on the polytetrafluoroethylene substrate, and the height of the protrusions is about 10 microns. Sizing and coating chitosan-modified graphene oxide slurry on a patterned polytetrafluoroethylene substrate to form a film with a film thickness of 60 microns. When the graphene oxide film is lifted off, there are also obvious " Spike".

[0046] 3) Laminate 10 layers of graphene oxide, pressurize to 5Mp, heat up to 60°C, hold heat and hold pressure for 1 hour to form a tightly bonded multi-layer graphene oxide film with a thickness of 600 microns.

[0047] 4) Cut the graphene oxide thick film into a square of 100×100mm, put it into a graphite mold, and then raise the temperature to 1200°C at a rate of 1°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com