Butyronitrile double-color glove and production process thereof

A technology of nitrile gloves and production process, applied in gloves, application, coating and other directions, can solve the problems of nitrile two-color gloves prone to peculiar smell, affecting user experience, inconvenient demoulding, etc. The effect of fast mold speed and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

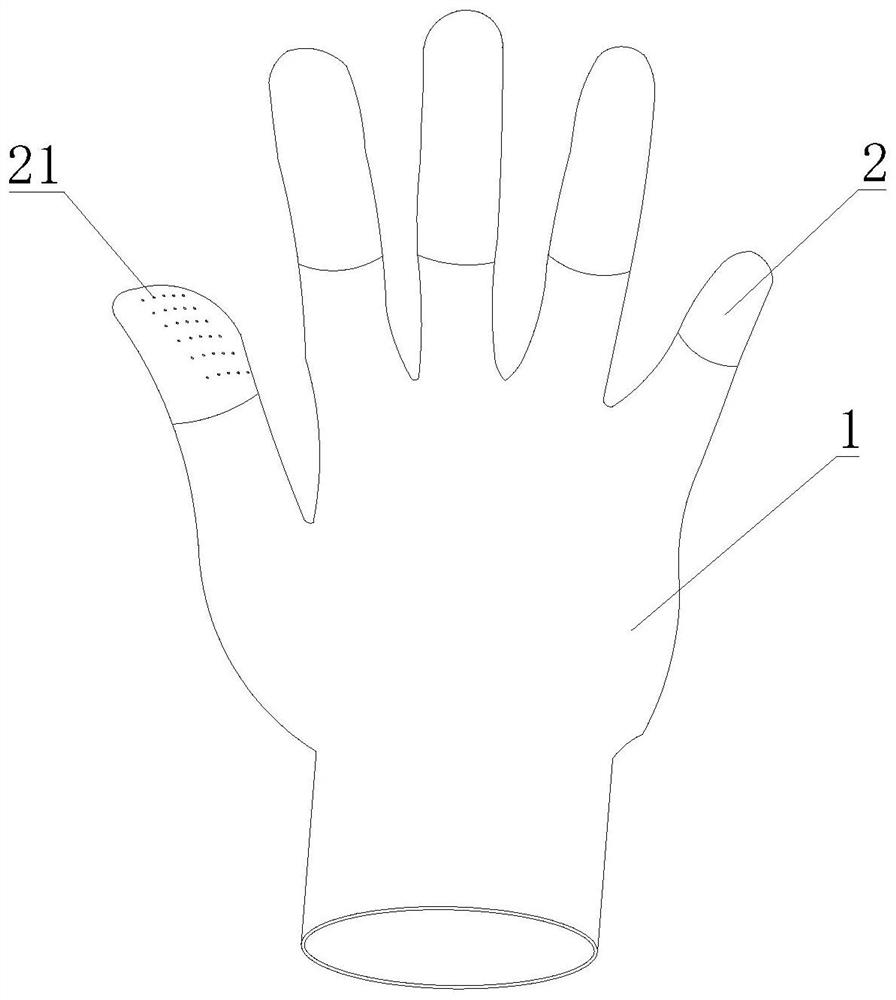

[0036] Such as figure 1 As shown, the present invention provides a kind of nitrile two-color glove, comprises nitrile glove main body 1, and one end of nitrile glove main body 1 is provided with fingertip 2, and the outer surface of fingertip 2 is provided with non-slip bump 21, and nitrile Glove main body 1 is made of nitrile rubber latex mixture, and nitrile rubber latex mixture is made of nitrile rubber latex, natural rubber latex, antioxidant, heat stabilizer, activated carbon, coloring agent, natural mold inhibitor, bridging agent and The composition of the antibacterial agent is calculated according to the distribution of the quantity, including the following distribution of raw materials: 50-70 parts of nitrile rubber latex, 30-40 parts of natural rubber latex, 0.5-1 part of antioxidant, 2-3 parts of heat stabilizer , 1-3 parts of activated carbon, 5-10 parts of coloring agent, 1-2 parts of natural antifungal agent, 2-5 parts of bridging agent, 1-3 parts of antibacteria...

Embodiment 2

[0039] Such as figure 1 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the heat stabilizer is a mixed metal stabilizer, the heat stabilizer is powdery, and the composition of the natural antifungal agent is 70%. mustard seed extract and 30% mugwort extract, the coloring agents are cinnabar, red earth, realgar, malachite green and heavy calcium carbonate, wollastonite, barite powder, talcum powder, mica powder, kaolin, etc. Any two of them, and the colorants are all natural colorants, and the colorants are taken in equal amounts.

[0040] In this embodiment, the heat stabilizer is mixed with nitrile rubber to improve the high temperature resistance of nitrile gloves and ensure its heat resistance during use. The mustard extract and mugwort extract work together to form a nitrile glove. Nitrile gloves increase the ability to inhibit the growth of mold, making the nitrile gloves free from fungal erosion, further ensuring the...

Embodiment 3

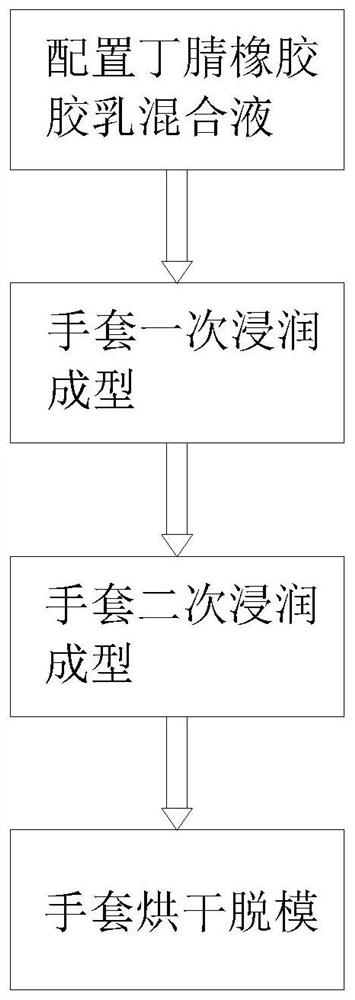

[0042] Such as Figure 1-2 Shown, on the basis of embodiment 1, embodiment 2, the present invention also provides a kind of nitrile two-color gloves production technique, this nitrile two-color gloves production technique, comprises the following steps:

[0043] A1. Configure the nitrile rubber latex mixture, specifically: the mixing temperature of each raw material of the nitrile rubber latex mixture is 110°C-140°C, the nitrile rubber latex mixture needs to be configured in two parts according to the colorant, and two parts of nitrile The rubber latex mixture is prepared in equal amounts, and after the nitrile rubber latex mixture is prepared, 2-3 operations of filtering and removing impurities are required;

[0044] A2. One-time infiltration molding of gloves, specifically: glove molds are required for one-time infiltration molding of gloves, and anti-sticking liquid is applied on the outer surface of the glove molds. Gloves need to be infiltrated for 20 seconds for one-time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com