Sealing ring with high strength and low pressure change and production process and edge cutting device of sealing ring

A sealing ring and low-pressure change technology, which is applied in the field of sealing rings and their production process and edge trimming device, can solve the problems of low strength of sealing rings, high pressure change, difficult to grasp the size, etc., and achieve the effect of accurate size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-strength and low-pressure variable sealing ring. The raw materials are composed of 22 parts of low temperature resistant silicone rubber, 55 parts of modified polyurethane resin rubber, 34 parts of polycarbodiimide, 10 parts of white carbon black, 8 parts of graphite, 2.5 parts of TMTD, 3 parts of emulsifier, 2.4 parts of anti-aging agent, 4.8 parts of nano-zinc oxide, 0.1 part of triallyl isocyanurate, 9 parts of sodium phytate, and 1.3 parts of glass fiber.

[0034] A production process of a high-strength and low-voltage variable sealing ring, comprising the following steps;

[0035] Step 1: Weigh low-temperature resistant silicone rubber, modified polyurethane resin rubber, polycarbodiimide, white carbon black, graphite, TMTD, emulsifier, anti-aging agent, nano zinc oxide, triallyl isocyanurate, Sodium phytate and glass fiber, and then put each material in a stirred tank for mixing, the mixing temperature is controlled at 70°C, and stirred at 600r / min for 45mi...

Embodiment 2

[0039]As another preferred embodiment of the present invention, the difference from Embodiment 1 is that a high-strength and low-pressure variable sealing ring is composed of 38 parts by weight of low-temperature resistant silicone rubber, 45 parts of modified polyurethane resin rubber, 12 parts of polycarbodiimide, 13 parts of white carbon black, 12 parts of graphite, 1.4 parts of TMTD, 6.3 parts of emulsifier, 5.8 parts of antioxidant, 2.6 parts of nano-zinc oxide, 0.05 part of triallyl isocyanurate, plant 7 parts of sodium bicarbonate, 1.9 parts of glass fiber.

[0040] A production process of a high-strength and low-voltage variable sealing ring, comprising the following steps;

[0041] Step 1: Weigh low-temperature resistant silicone rubber, modified polyurethane resin rubber, polycarbodiimide, white carbon black, graphite, TMTD, emulsifier, anti-aging agent, nano zinc oxide, triallyl isocyanurate, Sodium phytate and glass fiber, and then put each material in a stirred t...

Embodiment 3

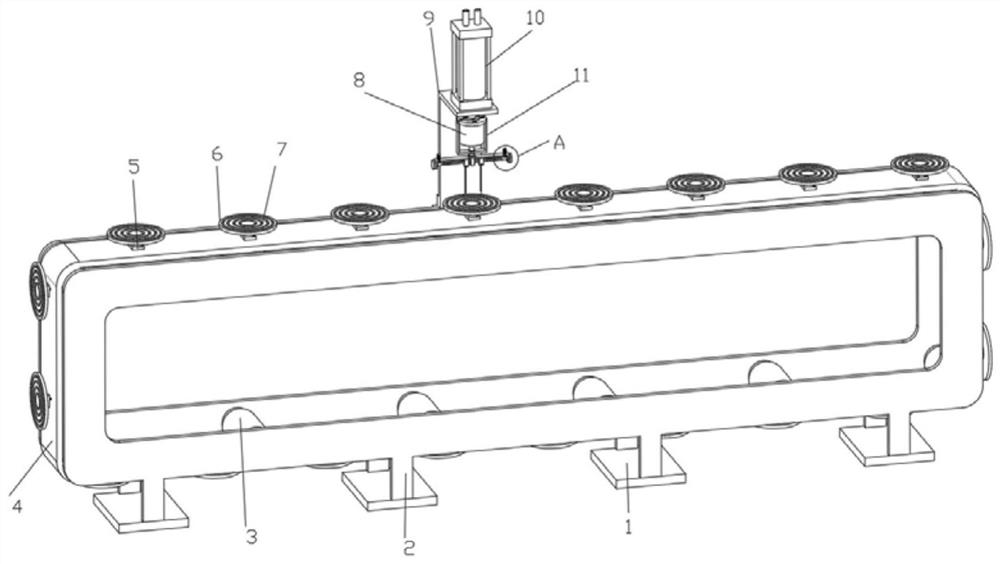

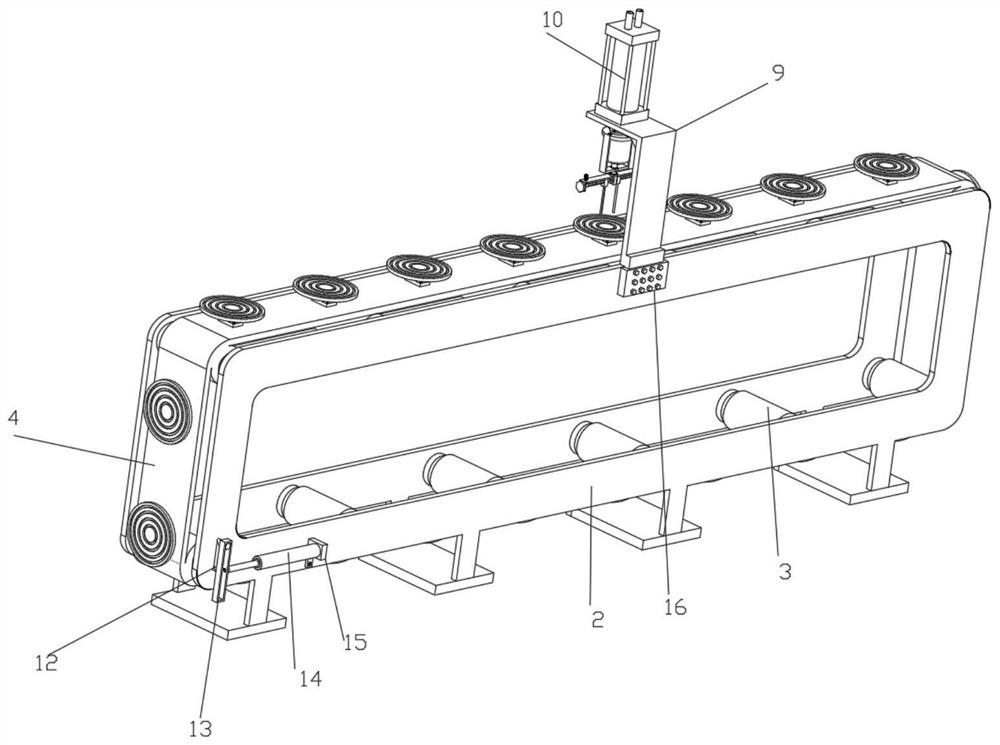

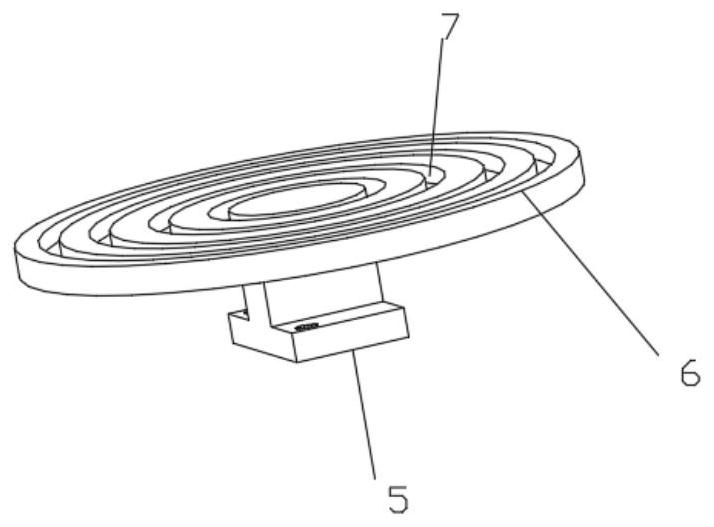

[0049] refer to figure 1 , 2 As shown in , 5, a trimming device of a sealing ring with high and low strength, the trimming device is the trimming device of step 3, including a base 1, and the top of the base 1 is connected with an intermittent pushing structure for the intermittent movement of the sealing ring, The intermittent push structure includes a support frame 2, a driving roller 3, a pulley 4, a Z-shaped rod 12, a back plate 13, an electric push rod 14 and an L-shaped block 15. The support frame 2 is fixedly installed on the top of the base 1, and the support frame 2 passes through The fixedly connected bearing is connected in rotation with the driving roller 3, the outer end of the driving roller 3 is fixedly connected with a pulley 4, the outer wall of the support frame 2 is fixedly installed with an L-shaped block 15, and the side wall of the L-shaped block 15 is fixedly installed with an electric push rod 14 , the output end of the electric push rod 14 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com