A preparation method of Cu-C-N metal-organic framework electrocatalyst for the reduction of nitrate to ammonia

A metal-organic framework and electrocatalyst technology, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of low catalytic efficiency and achieve high electrocatalytic activity, large specific surface area, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

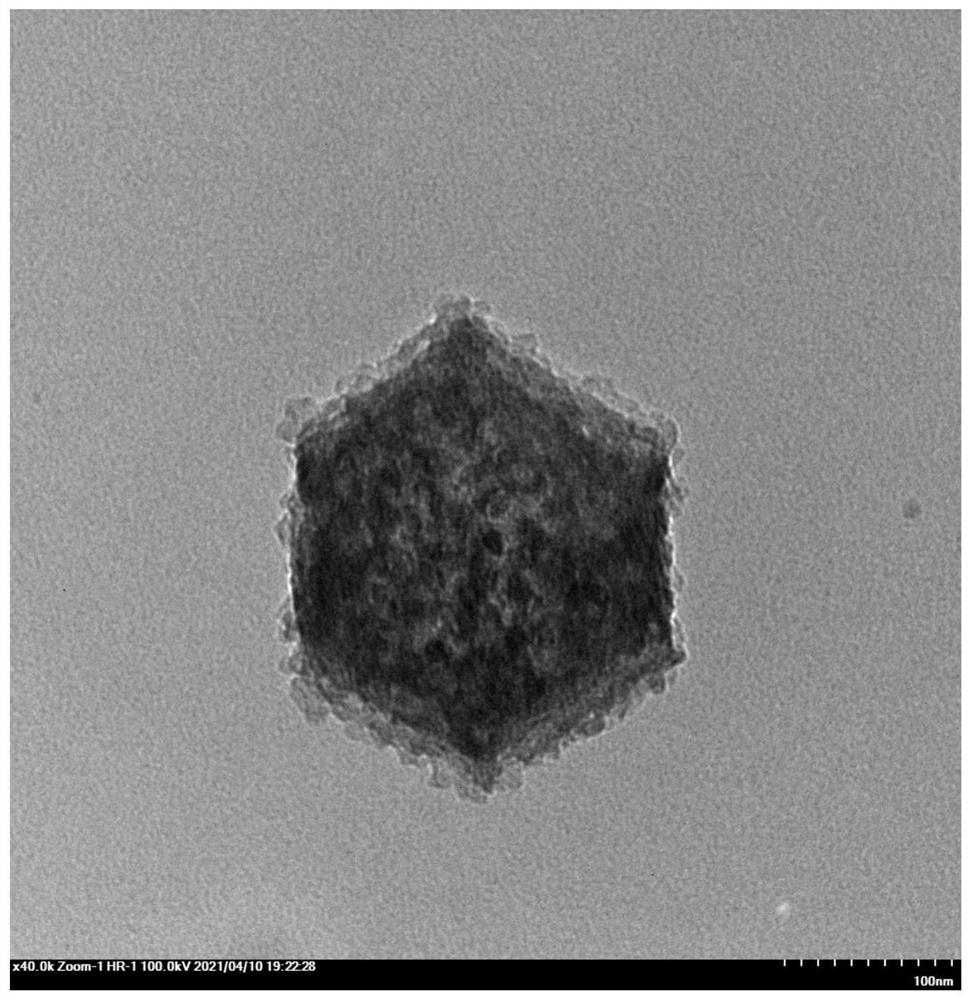

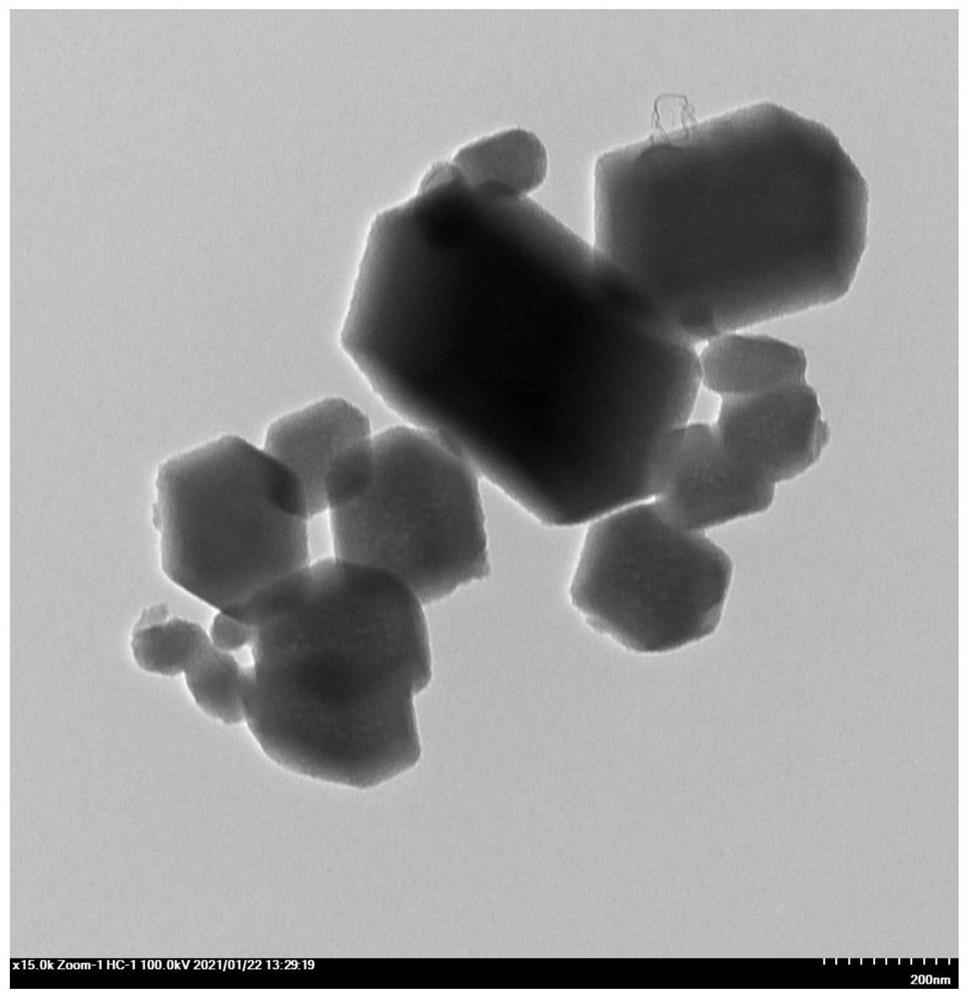

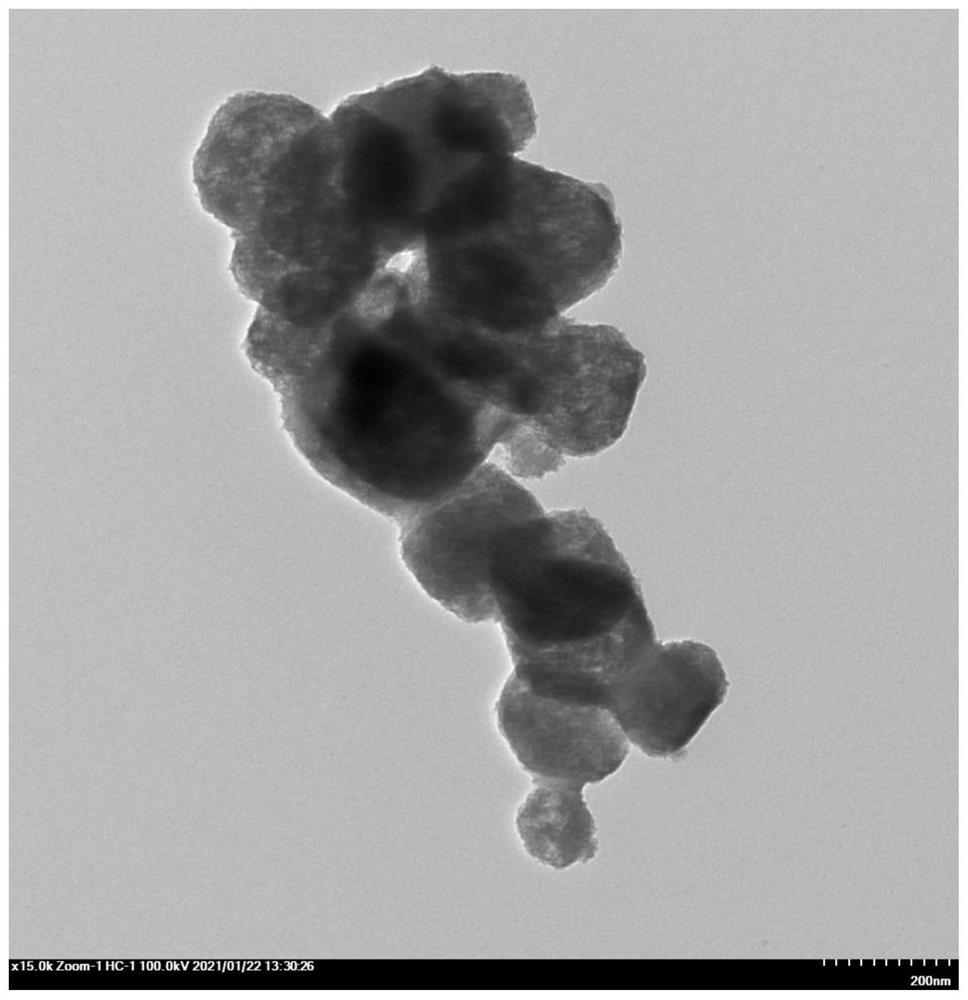

Image

Examples

Embodiment 1

[0043] A method for preparing a Cu-C-N metal-organic framework electrocatalyst for reducing nitric acid to ammonia, comprising the following preparation steps:

[0044] (1) 2-methylimidazole is dissolved in methanol solution to form the first solution whose concentration of 2-methylimidazole is 15mmol / L, and the order of addition is that methanol is added to 2-methylimidazole;

[0045] (2) Zinc nitrate hexahydrate and copper acetylacetonate are dissolved in methanol solution to form a second solution; the concentration of zinc nitrate hexahydrate in the second solution is 6mmol / L, and the order of adding the container is zinc nitrate hexahydrate, acetylacetonate Copper acetonate, methanol; The concentration of copper acetylacetonate in the second solution is 1.2mmol / L;

[0046] (3) Add the second solution to the first solution and sonicate for 15 minutes to form a suspension, transfer the suspension to the reaction kettle, and then react at a constant temperature of 150°C for 6 ...

Embodiment 2

[0050] A method for preparing a Cu-C-N metal-organic framework electrocatalyst for reducing nitric acid to ammonia, comprising the following preparation steps:

[0051] (1) 2-methylimidazole is dissolved in methanol solution to form the first solution whose concentration of 2-methylimidazole is 10mmol / L, and the order of addition is to add methanol to 2-methylimidazole;

[0052] (2) Zinc nitrate hexahydrate and copper acetylacetonate are dissolved in methanol solution to form a second solution; the concentration of zinc nitrate hexahydrate in the second solution is 3mmol / L, and the order of adding the container is zinc nitrate hexahydrate, acetylacetonate Copper acetonate, methanol; The concentration of copper acetylacetonate in the second solution is 1.5mmol / L;

[0053] (3) Add the second solution to the first solution and sonicate for 10 minutes to form a suspension, transfer the suspension to a reaction kettle, and then react at a constant temperature of 200°C for 4 hours, ...

Embodiment 3

[0057] A method for preparing a Cu-C-N metal-organic framework electrocatalyst for reducing nitric acid to ammonia, comprising the following preparation steps:

[0058] (1) 2-methylimidazole is dissolved in methanol solution to form the first solution whose concentration of 2-methylimidazole is 20mmol / L, and the order of addition is that methanol is added to 2-methylimidazole;

[0059] (2) Zinc nitrate hexahydrate and copper acetylacetonate are dissolved in methanol solution to form a second solution; the concentration of zinc nitrate hexahydrate in the second solution is 10mmol / L, and the order of adding to the container is zinc nitrate hexahydrate, acetylacetonate Copper acetonate, methanol; The concentration of copper acetylacetonate in the second solution is 1.5mmol / L;

[0060] (3) Add the second solution to the first solution and sonicate for 20 minutes to form a suspension, transfer the suspension to the reaction kettle, and then react at a constant temperature of 200°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com