Main case shell and positioning tool

A technology for positioning tooling and main box, applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of dislocation and offset of multiple plates, difficult to meet the accuracy, structural strength decline, etc., to achieve the connection accuracy High, reduce stress deformation, improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

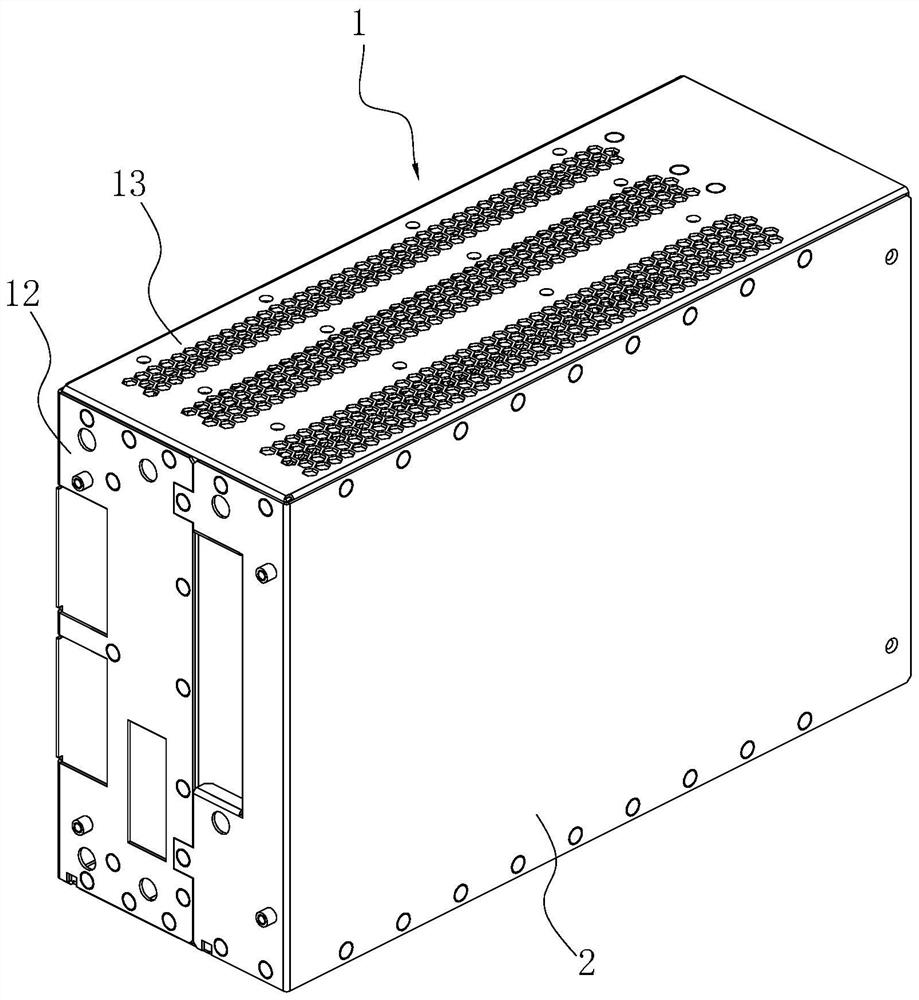

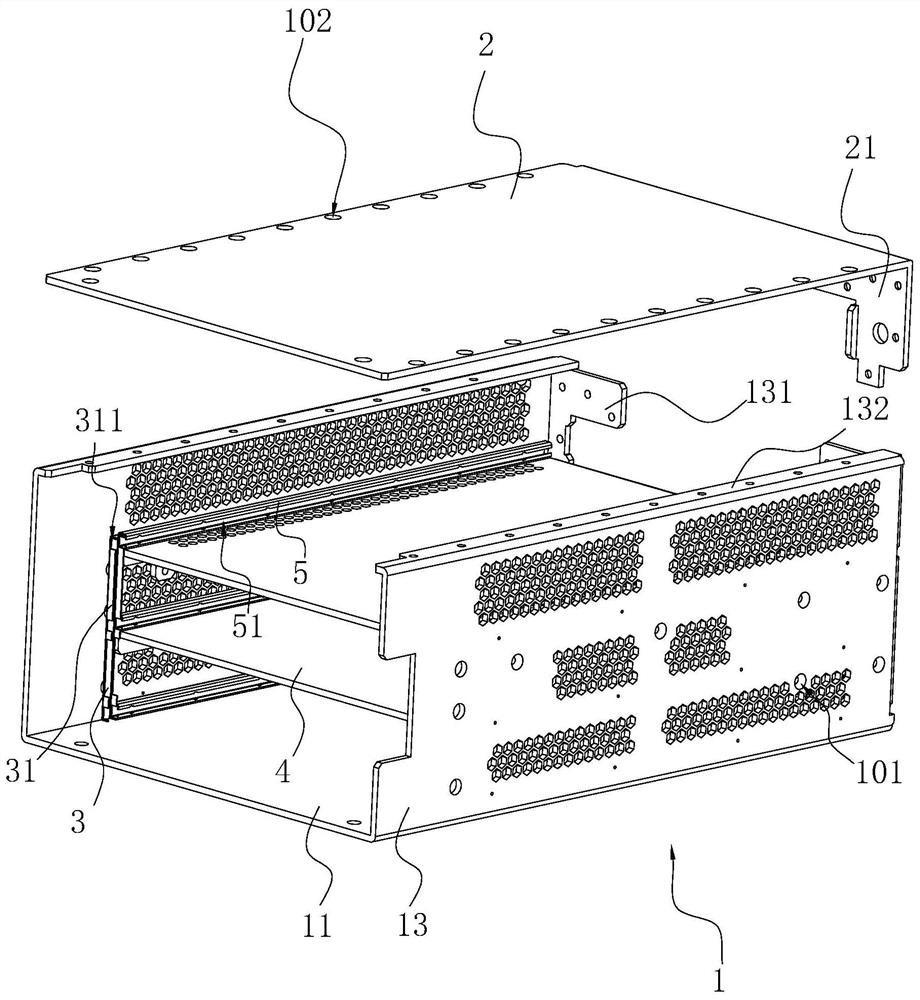

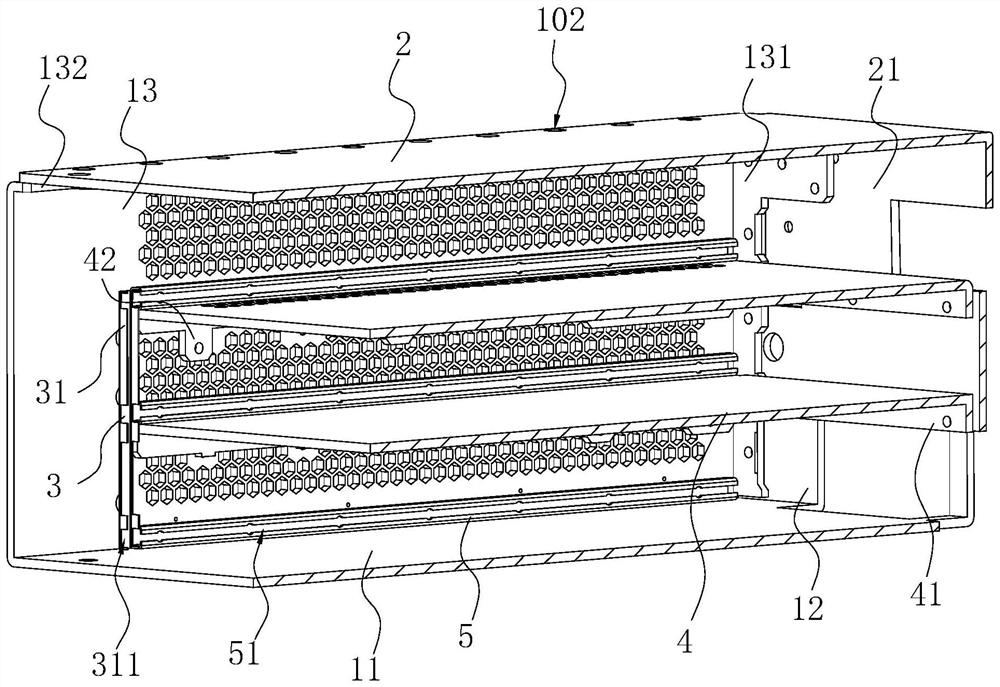

[0040] Refer figure 1with figure 2 The main box housing includes the body plate 1 and the side plate 2, and the body plate 1 includes a main board 11, a rear panel 12, and two side plates 13. The main board 11, the rear plate 12, and the two side plates 13 are all integrally formed, and the rear panel 12 and the side plate 13 are folded toward the same side and both are perpendicular to the main board 11, and the side plate 13 is bent towards the side edge of the rear panel 12. The slair portion 131 is formed, and the side plate 13 of the two side plates 13 is bent toward, and the rear panel 12 abuts against the abutment portion 131 near the side plate 13, the rear panel 12 and the abutment portion 131 can use the screw Secure or pull the rivetable mode, at this time, since the rear panel 12 and the abutting portion 131 are bent by one of the entire molded plates, the two screws are fixed or rivetically fixed, and the two do not disorderly. Thus, the fixed accuracy is relatively h...

Embodiment 2

[0054] The difference between the embodiment and the first embodiment is that

[0055] Refer Image 6 with Figure 7 The positioning plate 6 is also provided with a card attachment assembly 7, and the lock assembly 7 includes a restricting plate 71 and a buckle hook 72, and the restricting plate 71 is provided with two restriction plates 71 and the positioning plate 6 integrally formed, two restrictions. The plates 71 are respectively disposed on both sides of the positioning plate 6, and the restricting plate 71 and the seating profile of the positioning plate 6 are U-shaped in the width direction.

[0056] Refer Figure 7 with Figure 8 The hook 72 is made of a high molecular resin to reduce the hook 72 to scratch the edge plate 13, the fastening section 72 includes a strip structure and includes a connecting portion 721 and a fastener 722, a connecting portion 721 and a buckle The connecting portion 722 is integrated, and the connecting portion 721 is fixedly coupled to one side su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com