Shock-resistant and corrosion-resistant bonded neodymium-iron-boron magnet and preparation method thereof

A NdFeB, corrosion-type technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems that the magnet has no protective layer, the magnet is easy to be corroded, and affects the performance of the magnet, so as to achieve the ratio of raw materials Scientific and reasonable, improve the anti-fall and anti-seismic performance, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

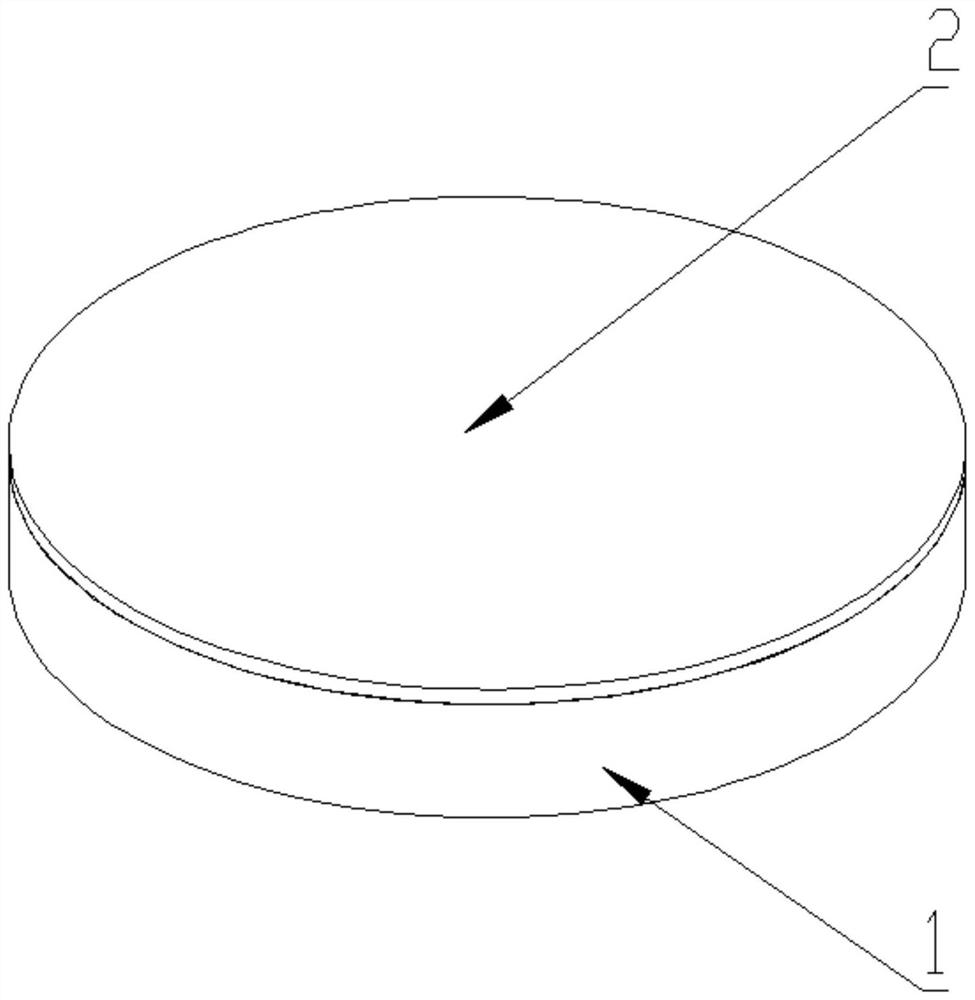

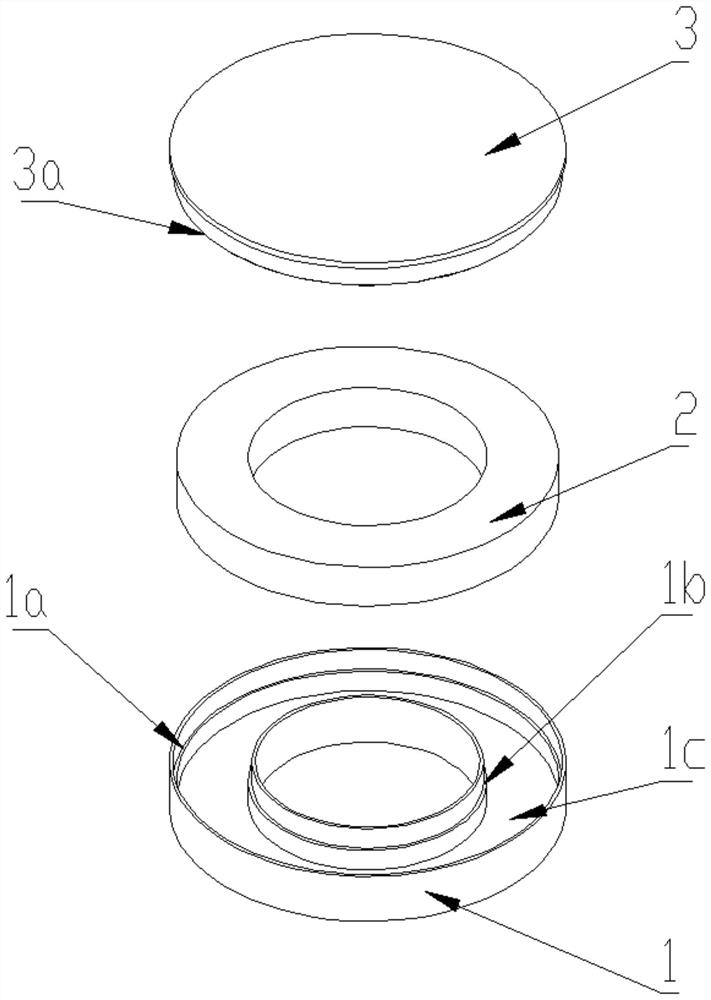

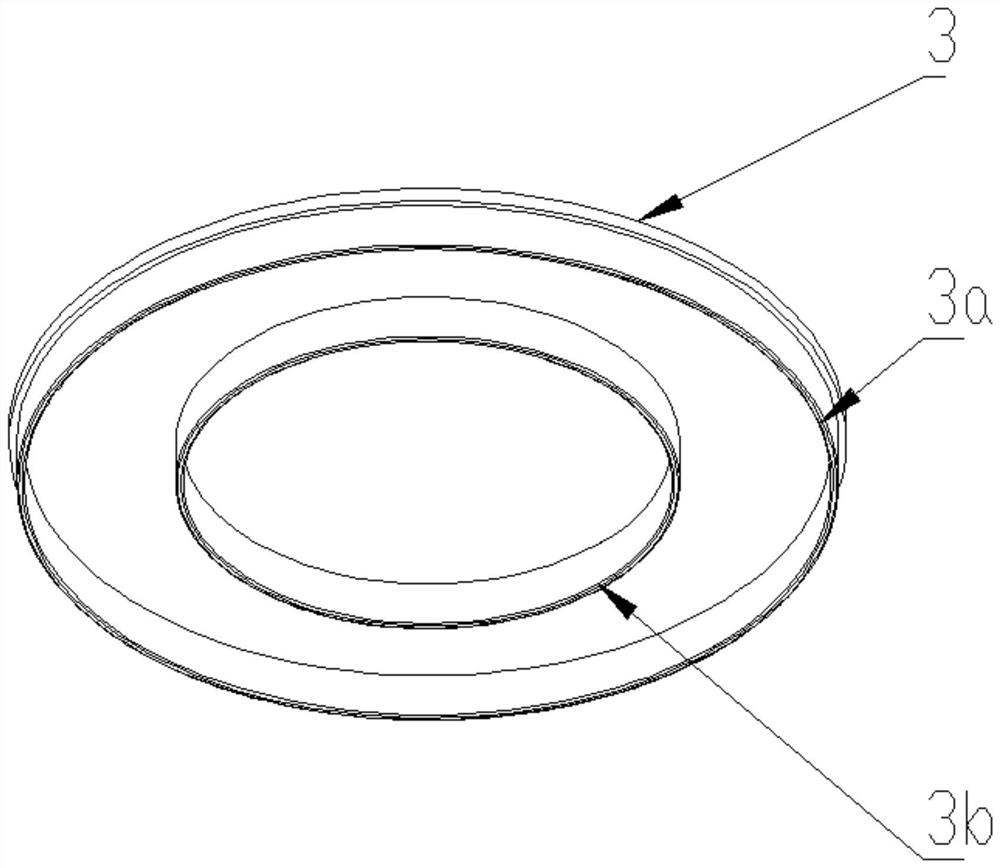

[0038] An anti-shock and corrosion-resistant bonded NdFeB magnet. The main body 2a of the magnet is made of the following raw materials in parts by weight: 95.5 parts of NdFeB magnetic powder, 1.8 parts of thermosetting adhesive, 0.5 part of coupling agent, and lubricant 0.4 parts, 0.4 parts of curing agent, 0.8 parts of accelerator, and 0.6 parts of reinforcing agent; the corrosion-resistant coating 2c is made of the following raw materials in parts by weight: 75-85 parts of aluminum, 8-20 parts of copper, rare earth 1 to 2 parts, 0.1 to 0.5 parts of bismuth.

[0039] In this embodiment, a method for preparing an anti-seismic and corrosion-resistant bonded NdFeB magnet, the steps are as follows:

[0040] Step 1: Take a certain amount of NdFeB magnetic powder and thermosetting binder respectively, under the protection of an inert gas such as nitrogen or argon, use a planetary mixer or other mixing equipment to stir and mix, mix evenly for 15-60 minutes, and obtain the pre- Mi...

Embodiment 2

[0049] An anti-shock and corrosion-resistant bonded NdFeB magnet, the magnet main body 2a is made of the following component raw materials in parts by weight: 95 parts of NdFeB magnetic powder, 1.9 parts of thermosetting binder, 0.6 part of coupling agent, lubricant 0.5 parts, 0.5 parts of curing agent, 0.9 parts of accelerator, and 0.6 parts of reinforcing agent; the corrosion-resistant coating 2c is made of the following components by weight: 75-85 parts of aluminum, 8-20 parts of copper, rare earth 1 to 2 parts, 0.1 to 0.5 parts of bismuth.

[0050] In this embodiment, a method for preparing an anti-seismic and corrosion-resistant bonded NdFeB magnet, the steps are as follows:

[0051] Step 1: Take a certain amount of NdFeB magnetic powder and thermosetting binder respectively, under the protection of an inert gas such as nitrogen or argon, use a planetary mixer or other mixing equipment to stir and mix, mix evenly for 15-60 minutes, and obtain the pre- Mixture;

[0052] ...

Embodiment 3

[0060] An anti-seismic and corrosion-resistant bonded NdFeB magnet. The main body 2a of the magnet is made of the following raw materials in parts by weight: 95 parts of NdFeB magnetic powder, 1.8 parts of thermosetting adhesive, 0.6 part of coupling agent, lubricant 0.5 parts, 0.5 parts of curing agent, 0.8 parts of accelerator, and 0.7 parts of reinforcing agent; the corrosion-resistant coating 2c is made of the following components by weight: 75-85 parts of aluminum, 8-20 parts of copper, rare earth 1 to 2 parts, 0.1 to 0.5 parts of bismuth.

[0061] In this embodiment, a method for preparing an anti-seismic and corrosion-resistant bonded NdFeB magnet, the steps are as follows:

[0062] Step 1: Take a certain amount of NdFeB magnetic powder and thermosetting binder respectively, under the protection of an inert gas such as nitrogen or argon, use a planetary mixer or other mixing equipment to stir and mix, mix evenly for 15-60 minutes, and obtain the pre- Mixture;

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com