Polypropylene ultra-silence pipeline and preparation method thereof

A polypropylene, ultra-quiet technology, applied in chemical instruments and methods, tubular articles, other household appliances, etc., can solve the problems of poor dispersion compatibility of inorganic fillers, limited mute effect of pipes, and reduced mechanical properties of pipes, etc. Achieve good mute effect and mechanical properties, excellent heat resistance and chemical resistance, and improve compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

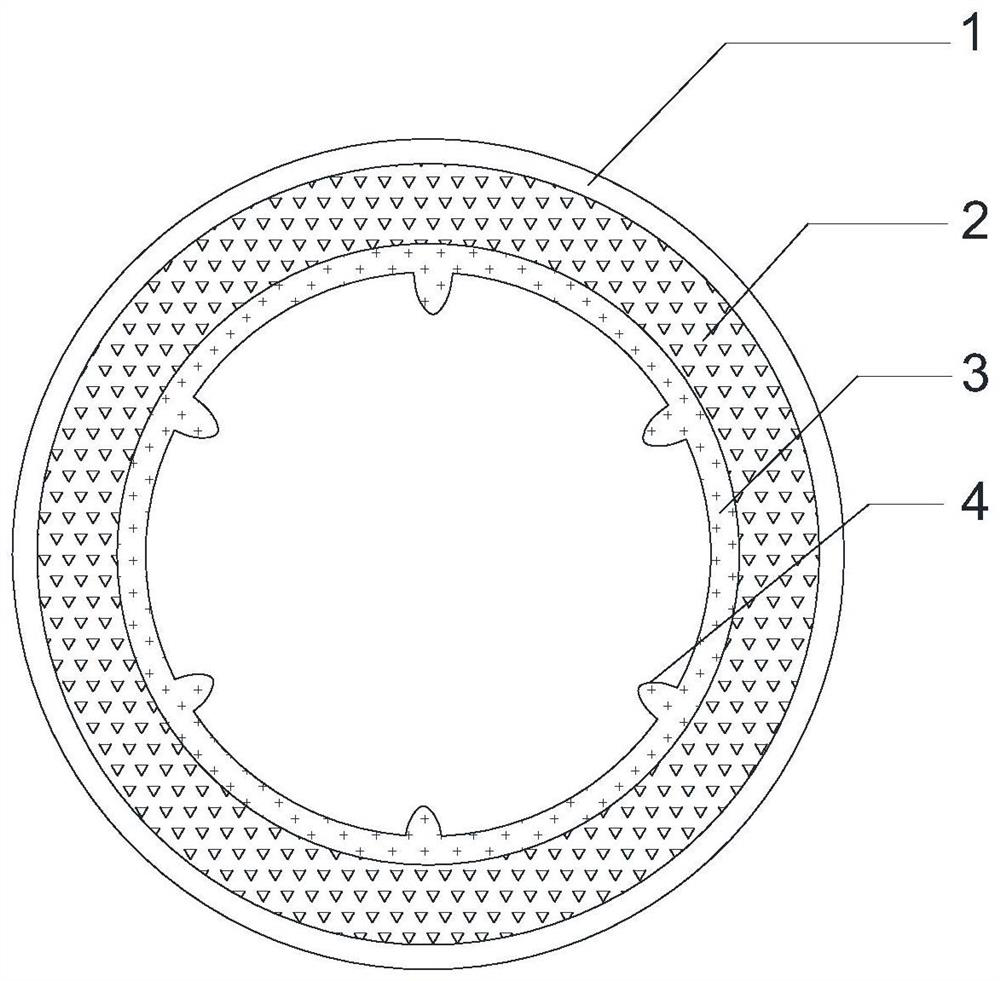

[0037] A polypropylene ultra-quiet pipe, such as figure 1 As shown, the pipe wall includes an outer layer 1, a middle foam layer 2, and an inner reinforcement layer 3 arranged in sequence, and the inner wall of the inner reinforcement layer is provided with 6 spiral reinforcements uniformly arranged along the inner wall and integrally formed with the inner reinforcement layer. tendon 4. Among them, the thickness of the outer layer is 1mm, the thickness of the middle reinforcement layer is 4mm, the thickness of the inner reinforcement layer is 1mm, the height of the reinforcement rib is 3mm; the inner diameter of the pipe is 12mm.

[0038] In parts by weight, the components of the outer layer material include: 85 parts of polypropylene copolymer (Sinopec EPS30R), 2 parts of PP masterbatch (Shenzhen Daxing Chemical Co., Ltd.), 2 parts of calcium stearate, and 1010 parts of antioxidant 0.8 parts, UV-531 0.3 parts; the components of the middle foam layer material include: 85 part...

Embodiment 2

[0049] A polypropylene ultra-quiet pipe, the pipe wall includes an outer layer, a middle foam layer and an inner reinforcement layer arranged in sequence, and the inner wall of the inner reinforcement layer is provided with 5 helical pipes uniformly arranged along the inner wall and integrally formed with the inner reinforcement layer. of stiffeners. Among them, the thickness of the outer layer is 2mm, the thickness of the middle reinforcement layer is 3mm, the thickness of the inner reinforcement layer is 1mm, the height of the reinforcement rib is 4mm; the inner diameter of the pipe is 12mm.

[0050] In parts by weight, the components of the outer layer material include: 80 parts of copolymerized polypropylene (Sinopec EPS30R), 1 part of PP masterbatch (Shenzhen Daxing Chemical Co., Ltd.), 1 part of calcium stearate, and 1010 parts of antioxidant 0.5 parts, UV-531 0.2 parts; the components of the middle foam layer material include: 80 parts of metal-organic framework grafted...

Embodiment 3

[0061] A polypropylene ultra-quiet pipe, the pipe wall includes an outer layer, a middle foam layer, and an inner reinforcement layer arranged in sequence, and the inner wall of the inner reinforcement layer is provided with 6 helical pipes uniformly arranged along the inner wall and integrally formed with the inner reinforcement layer. of stiffeners. Among them, the thickness of the outer layer is 1mm, the thickness of the middle reinforcement layer is 5mm, the thickness of the inner reinforcement layer is 1mm, the height of the reinforcement rib is 5mm; the inner diameter of the pipe is 12mm.

[0062] In parts by weight, the components of the outer layer material include: 90 parts of copolymerized polypropylene (Sinopec EPS30R), 3 parts of PP masterbatch (Shenzhen Daxing Chemical Co., Ltd.), 3 parts of calcium stearate, and 1010 parts of antioxidant 0.5 parts, 0.5 parts of antioxidant 168, 0.5 parts of UV-531; the components of the middle foam layer material include: 90 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com