Organic silica gel for potting IGBT (Insulated Gate Bipolar Translator) module

A technology of silicone and silicone gel, applied in the direction of adhesives, etc., can solve problems such as difficult to meet the use requirements, and achieve excellent electrical properties, low viscosity, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

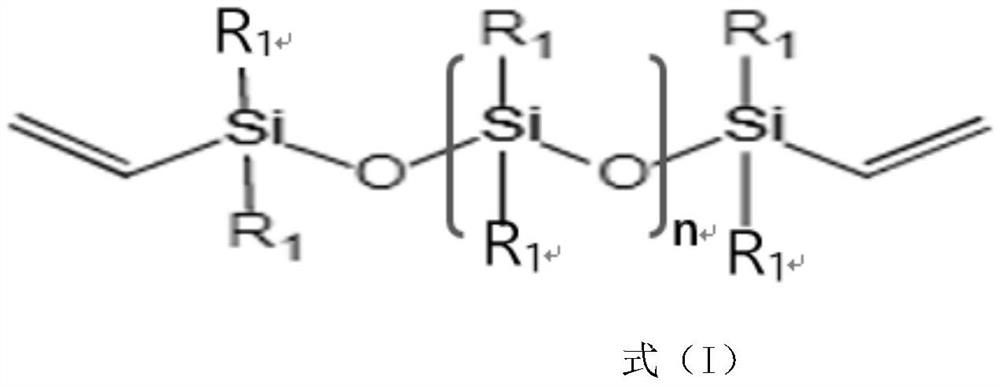

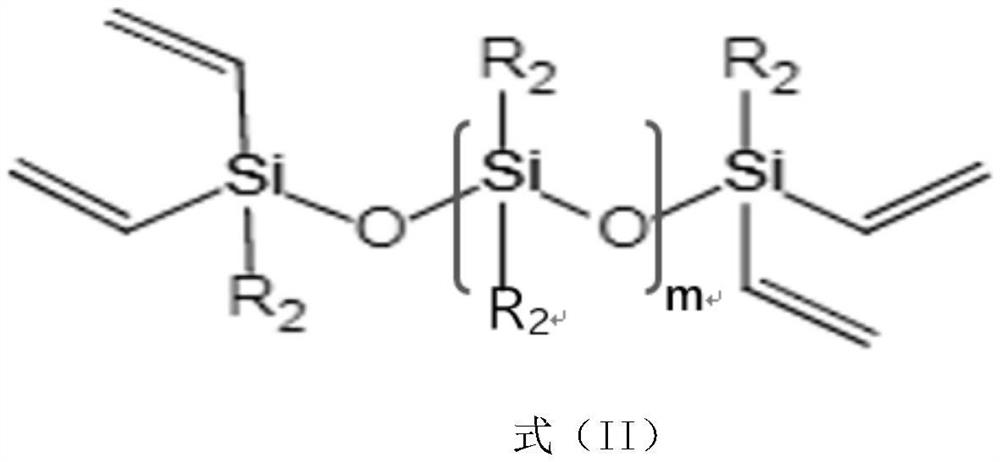

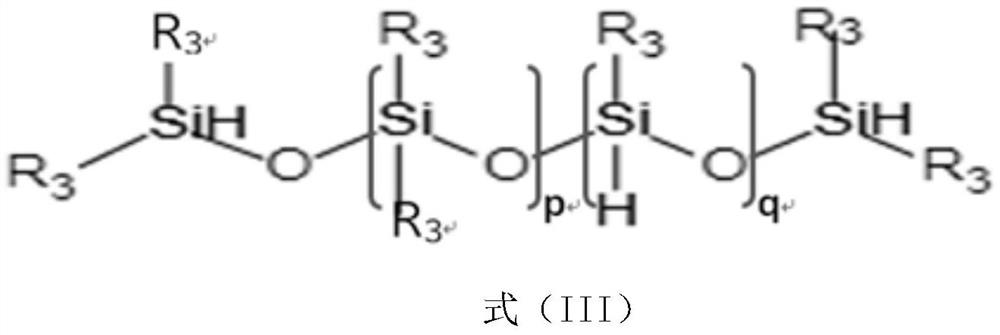

[0033] Vinyl-terminated polysiloxane (viscosity is 500mPa·s, vinyl content is 0.4%, R 1 is methyl, volatile matter 0.32%) 100 parts, organopolysiloxane with formula (II) structure (viscosity is 1000mPa·s, vinyl content is 0.6%, R 2 3 parts of methyl, 0.28% volatile matter), hydrogen-containing silicone oil with the structure of formula (Ⅲ) (viscosity is about 120mPa·s, hydrogen content is 0.15%, R 3 is methyl, volatile matter 0.39%) 4.13 parts, at this moment, through calculation, the ratio of the molar weight of the silicon-hydrogen bond in the hydrogen-containing silicone oil to the molar weight sum of the vinyl groups in the A and B components is 0.4. As a reaction inhibitor, 0.025 parts of ethynyl cyclohexanol was mixed and stirred for 5 minutes, then 0.27 parts of a platinum catalyst (Pt concentration: 3000 ppm) was added, and mixed and stirred for 5 minutes to obtain a silica gel composition. After the composition is evacuated, it is poured into a mold and an IGBT modul...

Embodiment 2

[0035] Vinyl-terminated polysiloxane (viscosity of 1000mPa·s, vinyl content of 0.3%, R 1 is methyl, volatile matter 0.26%) 100 parts, organopolysiloxane with formula (II) structure (viscosity is 500mPa·s, vinyl content is 0.8%, R 2 It is methyl, 0.35% volatile matter) 6 parts, has the structure of formula (Ⅲ) hydrogen-containing silicone oil (viscosity is 80mPa·s, hydrogen content is 0.2%, R 3 is methyl, volatile matter 0.42%) 3.85 parts, at this moment, through calculation, the ratio of the molar weight of the silicon-hydrogen bond in the hydrogen-containing silicone oil to the molar weight sum of the vinyl groups in the A and B components is 0.60. As a reaction inhibitor, 0.02 parts of cyclic vinylsiloxane were mixed and stirred for 5 minutes, then 0.033 parts of platinum catalyst (Pt concentration: 3000 ppm) was added, and mixed and stirred for 5 minutes to obtain a silicone gel composition. After the composition is evacuated, it is poured into a mold and an IGBT module, a...

Embodiment 3

[0037] Vinyl-terminated polysiloxane (viscosity is about 2000mPa·s, vinyl content is 0.2%, R 1 is methyl, volatile matter 0.21%) 100 parts, organopolysiloxane with formula (II) structure (viscosity is about 400mPa·s, vinyl content is 1.0%, R 2 It is methyl, volatile matter 0.38%) 10 parts, hydrogen-containing silicone oil with formula (Ⅲ) structure (viscosity is about 50mPa·s, hydrogen content is 0.35%, R 3 is methyl, volatile matter 0.44%) 2.54 parts, at this moment, through calculation, the ratio of the molar weight of the silicon-hydrogen bond in the hydrogen-containing silicone oil and the molar weight summation of the vinyl groups in the A and B components is 0.8. As a reaction inhibitor, 0.1 part of cyclic vinyl siloxane was mixed and stirred for 5 minutes, then 0.33 parts of platinum catalyst (Pt concentration: 3000 ppm) was added, and mixed and stirred for 5 minutes to obtain a silicone gel composition. After the composition is evacuated, it is poured into a mold and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com