Method for connecting polysilazane with silicon carbide

A technology of polysilazane and silicon carbide, which is applied in the field of polysilazane connection with silicon carbide, can solve problems such as low fracture toughness, brittle fracture, and affecting processing quality, and achieve high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

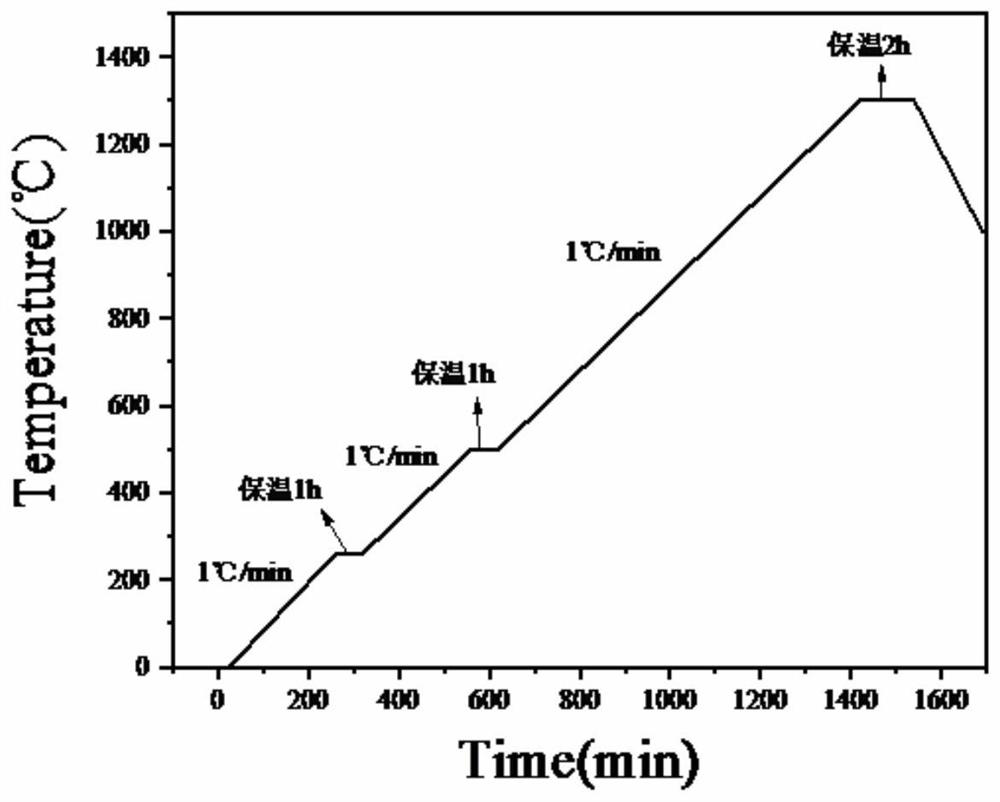

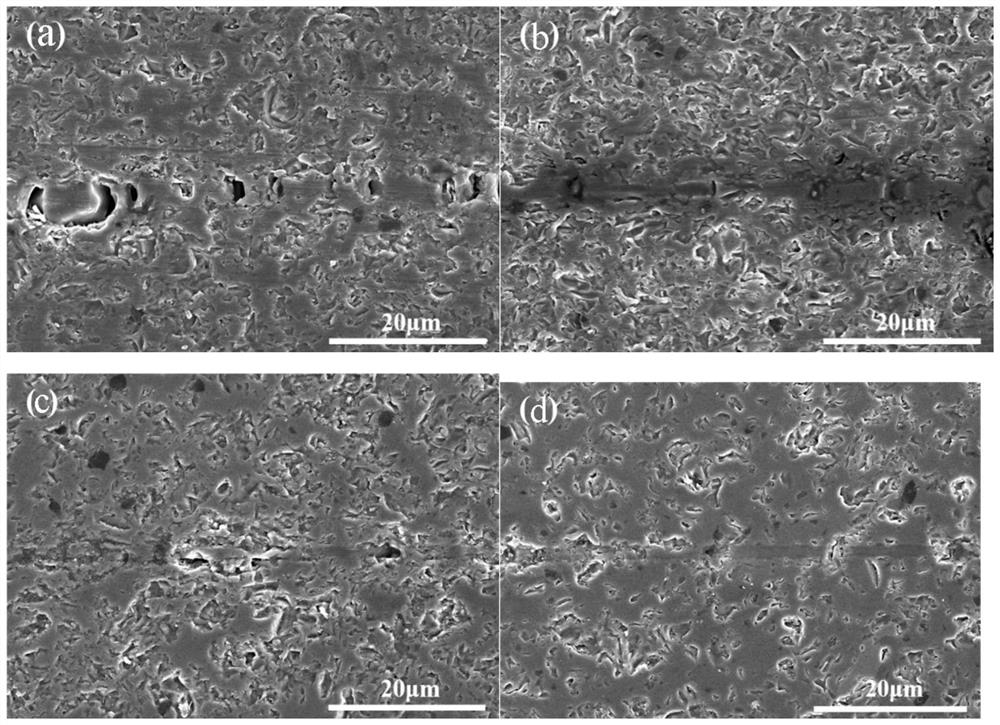

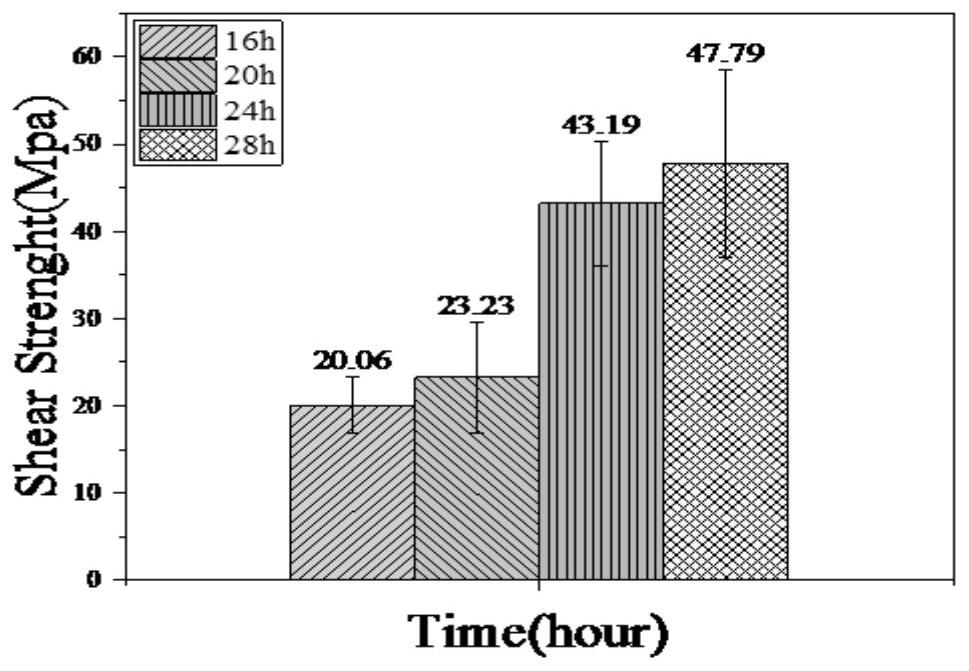

[0024] The silicon carbide used in this example is pressureless silicon carbide. After the silicon carbide is cut, it is ultrasonically cleaned in alcohol, dried with gauze, and polysilazane is dropped on the surface of the silicon carbide with a rubber dropper. Silazane is uniformly diffused on the surface of the silicon carbide substrate to obtain a pressureless silicon carbide substrate coated with polysilazane; then two pressureless silicon carbide substrates coated with polysilazane are stacked together to obtain Sample; put the sample in a graphite crucible, and apply 0.1N axial force on the sample, in the debinding furnace, at a heating rate of 1°C / min, raise the temperature to 140°C for cross-linking and curing; after cross-linking and curing The sample is placed in the 1500°C tube furnace of Huan Technology, and the axial force of 0.1N is also applied to the sample, and then heat treatment is carried out under the nitrogen atmosphere (the atmosphere flow rate of nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com