Acetophenone oxime ester imidazole derivative as well as preparation method and application thereof

A technology of acetophenone oxime ester imidazole and derivatives is applied in the field of acetophenone oxime ester imidazole derivatives and preparation thereof, and can solve the problems of few activity reports, no activity reports and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

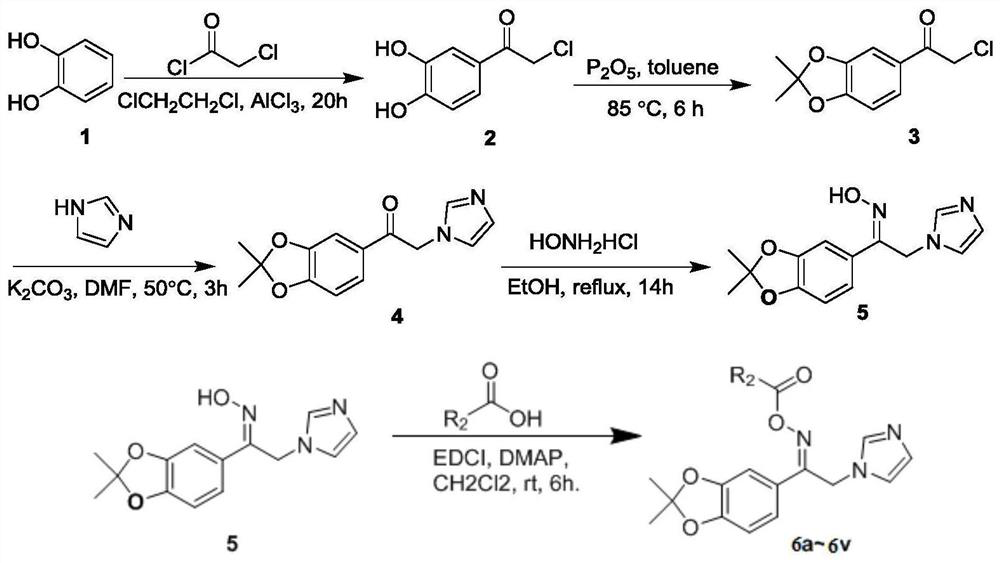

Method used

Image

Examples

Embodiment 1

[0033] Preparation of (E)-1-(2,2-dimethylbenzo[d][1,3]dioxol-5-yl)-2-(1H-imidazol-1-yl)ethanone oxime ester method, including the following steps:

[0034] (1) Preparation of 2-chloro-1-(3,4-dihydroxyphenyl)ethanone (compound 2):

[0035] Add 6.0 g, 45 mmol of aluminum chloride to 20 mL of 1,2-dichloroethane, stir at 5°C for 30 min, then slowly add 4.0 g, 36.2 mmol of catechol (compound 1) under stirring conditions , and continued to stir for 20min, then added 4.4g, 38.6mmol of chloroacetyl chloride at 5°C, and naturally warmed up to room temperature, and then stirred at room temperature for 20h. After the reaction was completed, 70mL, 0.5mol / L of dilute hydrochloric acid solution was quenched, the reaction was stopped at the desired stage, and then naturally warmed to room temperature and stirred for 3 h, the solid was obtained by filtration and washed with water;

[0036] The wet solid is decolorized, specifically: the wet solid is dissolved in acetic acid aqueous solutio...

Embodiment 2

[0053] The same as the preparation steps of Example 1, the only difference is that the carboxylic acid compound is made of replace with Compound 6b was obtained as a colorless oil with a yield of 48%; 1 H NMR (500MHz, CDCl 3 )δ7.93(d, J=8.0Hz, 2H), 7.59(s, 1H), 7.30(d, J=8.0Hz, 2H), 7.22(s, 1H), 7.17(d, J=8.0Hz, 1H), 7.06(s, 1H), 6.97(s, 1H), 6.74(d, J=8.1Hz, 1H), 5.36(s, 2H), 2.44(s, 3H), 1.69(s, 6H); 13 C NMR (125MHz, CDCl 3 )δ163.26, 159.51, 150.54, 148.37, 144.75, 137.40, 130.05, 129.72, 129.56, 125.55, 125.05, 121.81, 119.38, 119.11, 108.37, 107.30, 42.22HR215.7c 22 h 21 N 3 o 4 392.1604[M+H] + , found 392.1601.

Embodiment 3

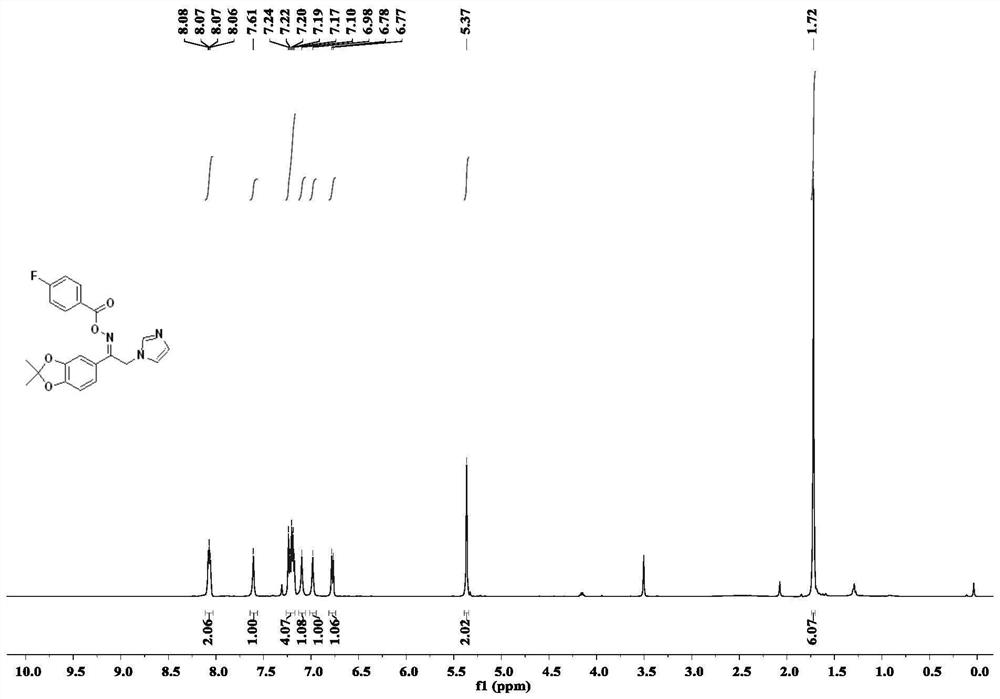

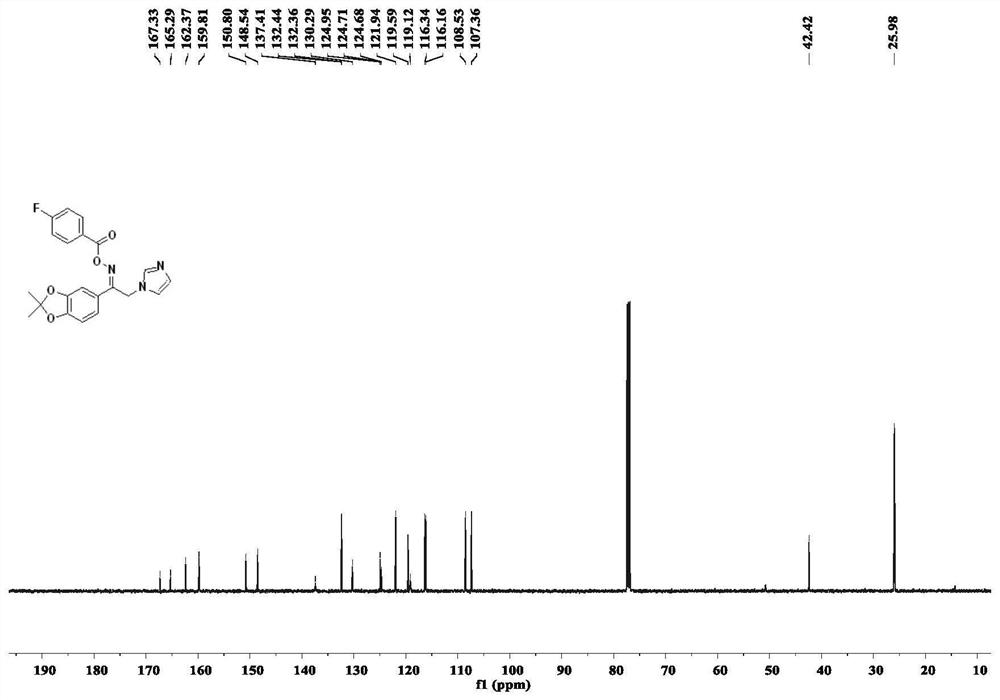

[0055] The same as the preparation steps of Example 1, the only difference is that the carboxylic acid compound is made of replace with Compound 6c was obtained as a colorless oil with a yield of 54%; 1 H NMR (500MHz, CDCl 3 )δ8.07(dd,J=7.7Hz,5.7Hz,2H),7.61(s,1H),7.26–7.15(m,4H),7.10(s,1H),6.98(s,1H),6.78( d,J=8.1Hz,1H),5.37(s,2H),1.72(s,6H); 13 C NMR (125MHz, CDCl 3 )δ166.31(d,J C-F =255.8Hz), 162.37, 159.81, 150.80, 148.54, 137.41, 132.40 (d, J C-F =9.5Hz), 130.29, 124.95, 124.69 (d, J = 3.0Hz), 121.94, 119.59, 119.12, 116.25 (d, J C-F =22.2Hz), 108.53, 107.36, 42.42, 25.98; .HRMS(ESI) m / z: calcd for C 21 h 18 FN 3 o 4 396.1354[M+H] + , found 396.1352.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com