Cellulose/carbon nanotube composite film as well as preparation method and application thereof

A carbon nanotube composite and carbon nanotube technology, applied in the field of cellulose/carbon nanotube composite film and its preparation, can solve the problem of sacrificing material mechanical properties, light weight, flexibility and processability, high filler addition and Problems such as sample thickness, high contact resistance and thermal resistance, etc., to achieve good mechanical flexibility, excellent mechanical properties, and improved electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

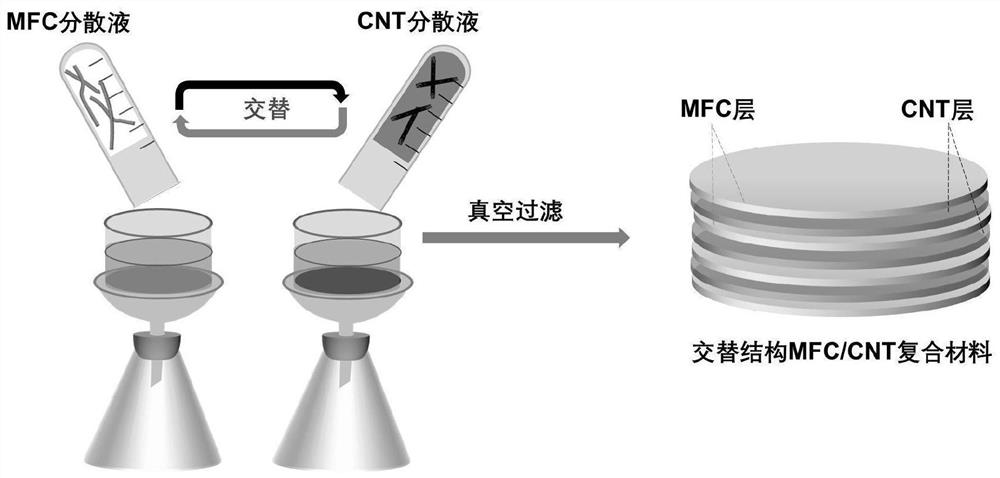

[0037] The present invention also provides a preparation method for the cellulose / carbon nanotube composite film described in the above technical solution, comprising the following steps:

[0038] The cellulose aqueous dispersion and the carbon nanotube aqueous dispersion are alternately filtered on the surface of the filter membrane, and the filter membrane is removed to obtain a cellulose / carbon nanotube composite film.

[0039] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0040] In the present invention, the concentration of the aqueous cellulose dispersion is preferably 0.1-2 mg / mL, more preferably 0.5-1 mg / mL. In the present invention, the preparation method of the aqueous cellulose dispersion preferably includes: mixing cellulose and water to obtain an aqueous cellulose dispersion. In the present invention, the type of the cellulose is the same as the cellulose in the cellulose ...

Embodiment 1

[0056] The microfibrillated cellulose is mixed with water to obtain a microfibrillated cellulose aqueous dispersion; the concentration of the microfibrillated cellulose in the microfibrillated cellulose aqueous dispersion is 0.5 mg / mL.

[0057] Carbon nanotubes, Triton X-100 and water are mixed to obtain a carbon nanotube aqueous dispersion; the concentration of carbon nanotubes in the carbon nanotube aqueous dispersion is 0.6mg / mL, and the mass fraction of Triton X-100 is 1wt %.

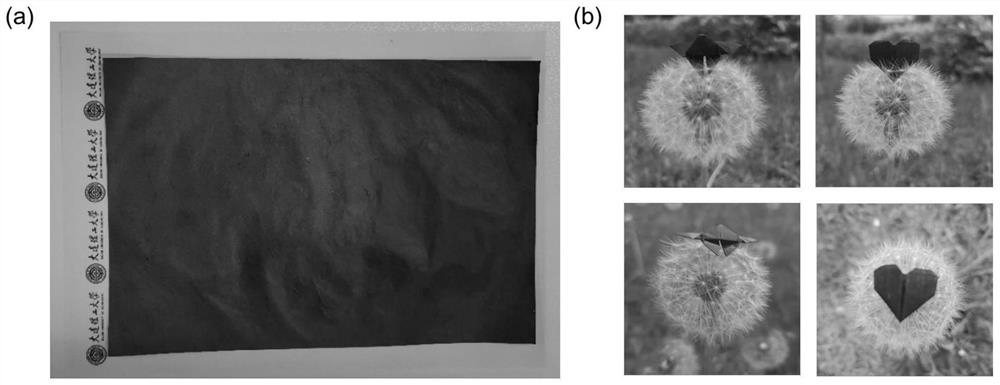

[0058] Using vacuum filtration, filter 15mL of the microfibrillated cellulose aqueous dispersion, 25mL of the carbon nanotube aqueous dispersion, and 15mL of the microfibrillated cellulose aqueous dispersion on the surface of a mixed fiber filter membrane with a pore diameter of 0.45 μm. solution, the vacuum degree is 0.1MPa; rinse the obtained composite film with a large amount of deionized water, then soak it in acetone bath several times to dissolve the mixed fiber filter membrane, and dry at roo...

Embodiment 2

[0060] The microfibrillated cellulose is mixed with water to obtain a microfibrillated cellulose aqueous dispersion; the concentration of the microfibrillated cellulose in the microfibrillated cellulose aqueous dispersion is 0.5 mg / mL.

[0061] Carbon nanotubes, Triton X-100 and water are mixed to obtain a carbon nanotube aqueous dispersion; the concentration of carbon nanotubes in the carbon nanotube aqueous dispersion is 0.6mg / mL, and the mass fraction of Triton X-100 is 1wt %.

[0062] Using vacuum filtration, filter 7.5mL of the microfibrillated cellulose aqueous dispersion, 8.33mL of the carbon nanotube aqueous dispersion, and 7.5mL of the microfibrillated fiber on the surface of a mixed fiber filter membrane with a pore diameter of 0.45 μm. plain water dispersion, 8.33mL of said carbon nanotube water dispersion, 7.5mL of said microfibrillated cellulose water dispersion, 8.33mL of said carbon nanotube water dispersion and 7.5mL of said microfibrillated cellulose water Di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com