A kind of kapok nanocellulose aerogel and its preparation method and application

A technology of nanocellulose and kapok fiber, applied in aerogel preparation, separation method, chemical instrument and method, etc., can solve environmental pollution caused by cellulose aerogel reusability, complex cellulose extraction method, oily liquid The recovery steps are complex and other problems, to achieve good lipophilicity and hydrophobicity, good hydrophobic effect, and reduce the preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

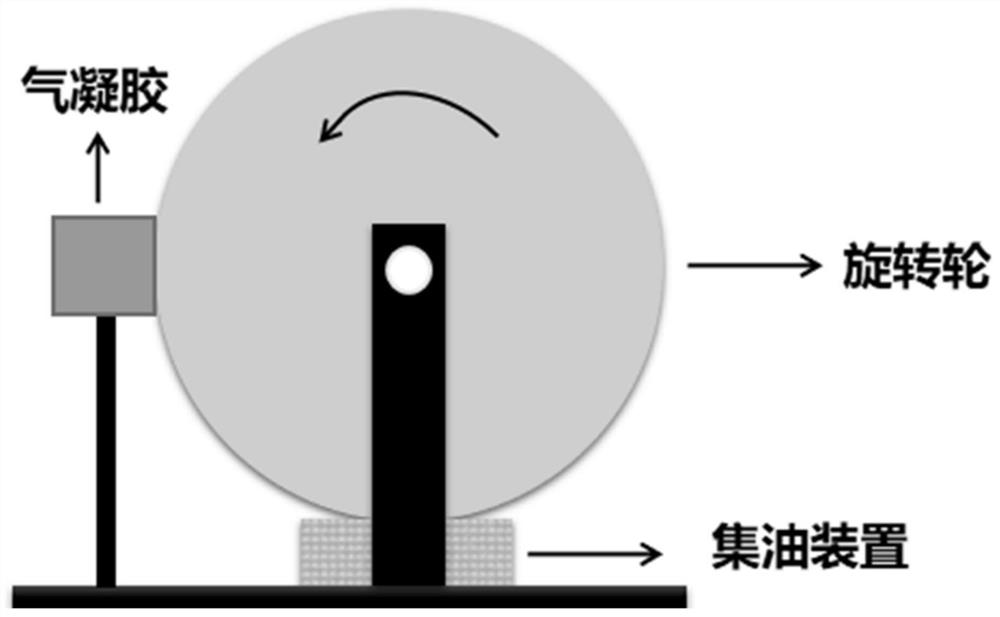

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a kapok nanocellulose aerogel adsorption material. The kapok nanocellulose obtained after microfibrillation and homogenization is configured into a uniform suspension, and the pH of the solution is adjusted between 3 and 3. Between 4 and 4, a silane coupling agent was added for hydrophobic modification, and kapok nanocellulose aerogel was prepared by freeze-drying after freezing. The specific operation steps are as follows:

[0028] Step 1. Extraction of kapok nanocellulose:

[0029] Put the kapok fiber into a 10wt% NaOH solution, and treat it at 80 °C for 1 h to remove impurities such as wax on the surface of the kapok fiber, and then rinse the lye on the fiber with deionized water; The kapok fiber pulp is obtained by beating treatment; and then the kapok pulp is put into a high-pressure homogenizer for homogenization treatment to obtain kapok nanocellulose. Take a cellulose solution with a kapok nanocellulose content o...

Embodiment 2

[0036] This embodiment provides a method for preparing a kapok nanocellulose aerogel adsorption material. The kapok nanocellulose obtained after microfibrillation and homogenization is configured into a uniform suspension, and the pH of the solution is adjusted between 3 and 3. Between 4 and 4, a silane coupling agent was added for hydrophobic modification, and kapok nanocellulose aerogel was prepared by freeze-drying after freezing. The specific operation steps are as follows:

[0037] Step 1. Extraction of kapok nanocellulose:

[0038] Put the kapok fiber into a 10wt% NaOH solution, and treat it at 80°C for 1 h to remove the wax on the surface of the kapok fiber, and then rinse the lye on the fiber with deionized water; then use a beater to beat the kapok fiber. The kapok fiber pulp is obtained; and then the kapok pulp is put into a high-pressure homogenizer for homogenization treatment to obtain kapok nanocellulose. Take a cellulose solution with a kapok nanocellulose con...

Embodiment 3

[0045]This embodiment provides a method for preparing a kapok nanocellulose aerogel adsorption material. The kapok nanocellulose obtained after microfibrillation and homogenization is configured into a uniform suspension, and the pH of the solution is adjusted between 3 and 3. Between 4 and 4, a silane coupling agent was added for hydrophobic modification, and kapok nanocellulose aerogel was prepared by freeze-drying after freezing. The specific operation steps are as follows:

[0046] Step 1. Extraction of kapok nanocellulose:

[0047] Put the kapok fiber into a 10wt% NaOH solution, and treat it at 80°C for 1 h to remove the wax on the surface of the kapok fiber, and then rinse the lye on the fiber with deionized water; then use a beating machine to beat the kapok fiber. kapok fiber pulp is obtained; the kapok pulp is then put into a high-pressure homogenizer for homogenization to obtain kapok nanocellulose. Take a cellulose solution with a kapok nanocellulose content of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com