Special starch/PLA-PGA-PBAT biodegradable compostable material and preparation method thereof

A biodegradable, special material technology, applied in the field of preparation, can solve the problems of consuming oil and energy, endangering human health, aggravating the greenhouse effect of white pollution, etc., and achieving the effect of improving mechanical properties and enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

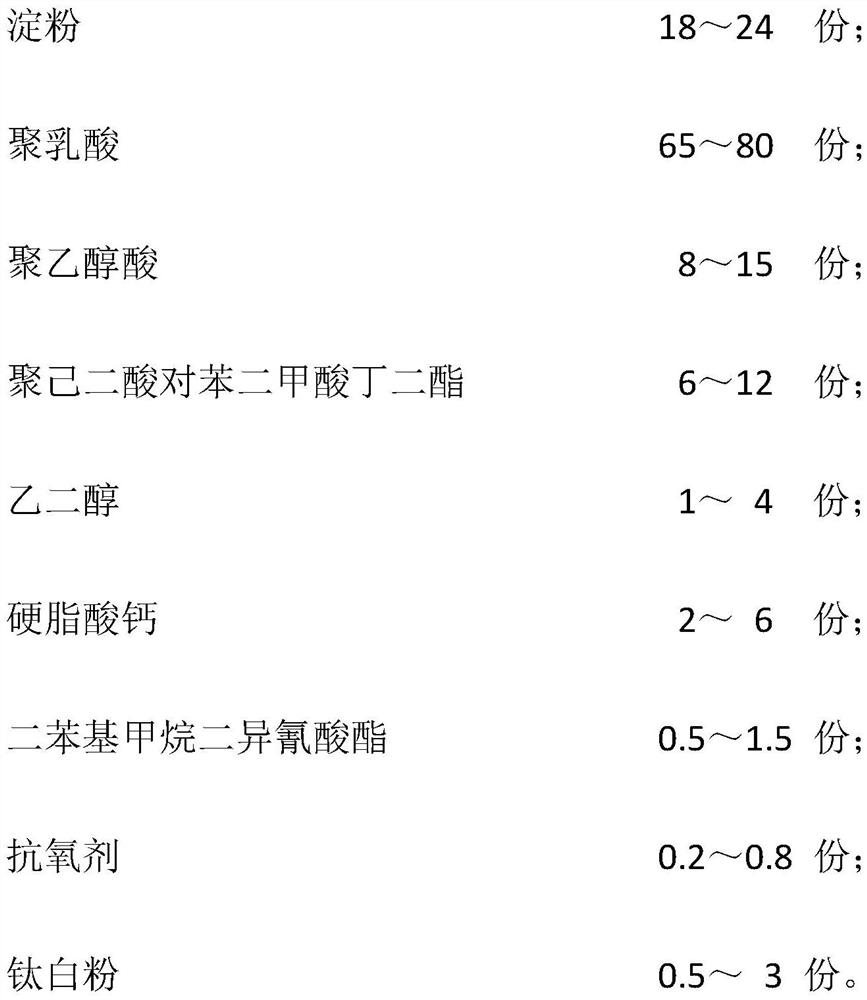

Method used

Image

Examples

preparation example Construction

[0040] Its preparation method of a kind of starch / PLA-PGA-PBAT biodegradable & compostable special material, comprises the following steps:

[0041] S1: Put starch, ethylene glycol, calcium stearate, diphenylmethane diisocyanate, titanium dioxide, and antioxidant into a high-speed stirrer that has been preheated to a constant temperature of 50-100°C and stir at high speed ;

[0042] S2: When the temperature of the material reaches 100-140°C, add polylactic acid, polyglycolic acid, and polybutylene adipate terephthalate and stir at a low speed for 1-3 minutes, then put it in a cooling mixer and cool down to 60-80°C Discharge spare;

[0043] S3: Put the premixed material obtained in step S2 into a twin-screw granulator with constant temperature at 180°C to 230°C, which is equipped with more than two exhaust ports, to melt, blend, extrude and granulate to obtain starch / PLA-PGA-PBAT Biodegradable & compostable special material.

[0044] The present invention adopts PLA, PGA, PB...

Embodiment 1

[0049] Its preparation method of a kind of starch / PLA-PGA-PBAT biodegradable & compostable special material, comprises the following steps:

[0050] S1: Put 20kg of corn starch, 5kg of hydroxypropyl starch, 1.4kg of ethylene glycol, 0.2kg of calcium stearate, 0.1kg of MDI, 0.6kg of titanium dioxide, and 0.5kg of antioxidant (1010) into the preheated constant temperature to 90 Stir at high speed in a high-speed stirrer at ℃;

[0051] S2: When the temperature of the material stirred at high speed in step S1 rises to 120°C, add 40kg of polylactic acid, 15kg of polyglycolic acid, and 20kg of polybutylene adipate terephthalate and stir for 2 minutes at a low speed, then put it into a cooling mixer Cool down to 70°C and discharge for later use;

[0052] S3: Put the premix obtained in step S2 into a constant temperature twin-screw granulator at 220°C with two or more exhaust ports to melt, blend, extrude and granulate to prepare starch / PLA-PGA-PBAT biodegradable & Compostable speci...

Embodiment 2

[0055] Its preparation method of a kind of starch / PLA-PGA-PBAT biodegradable & compostable special material, comprises the following steps:

[0056] S1: Put 24kg of corn starch, 6kg of hydroxypropyl starch, 1.8kg of ethylene glycol, 0.2kg of calcium stearate, 0.15kg of MDI, 0.6kg of titanium dioxide, and 0.5kg of antioxidant (1010) in proportion by weight. Stir at high speed in a high-speed stirrer that has been preheated to a constant temperature of 90°C;

[0057] S2: When the temperature of the material stirred at high speed in step S1 rises to 120°C, put in 40kg of PLA, 20kg of PGA, and 10kg of PBAT and stir at a low speed for 2 minutes, put it in a cooling mixer and cool it down to 40°C, and discharge it for later use;

[0058] S3: Put the premix obtained in step S2 into a constant temperature twin-screw granulator at 220°C with two or more exhaust ports to melt, blend, extrude and granulate to prepare starch / PLA-PGA-PBAT biodegradable & Compostable special material.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com