Energy-saving and environment-friendly combustion furnace with waste heat recycling function

A technology of waste heat recovery, energy saving and environmental protection, which is applied in the field of combustion furnaces, can solve the problems of non-reuse of heat, waste of resources, insufficient energy saving, etc., and achieve the effects of simple structure, reduction of burns, and reduction of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

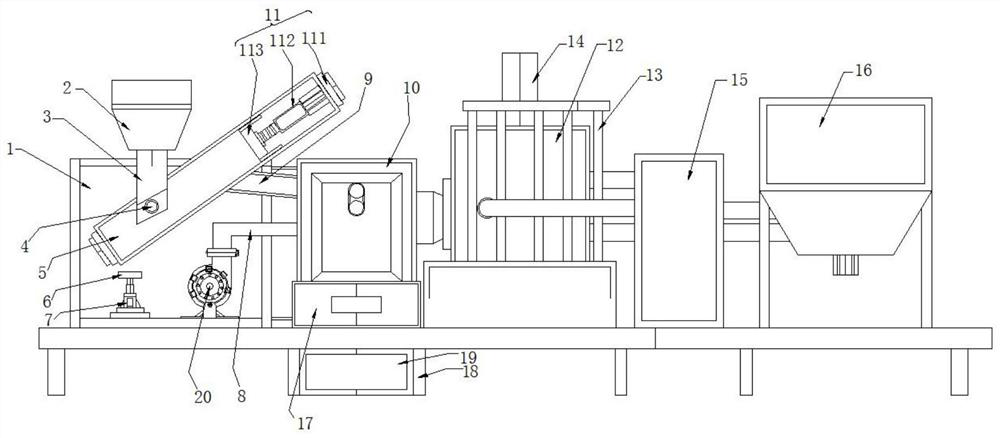

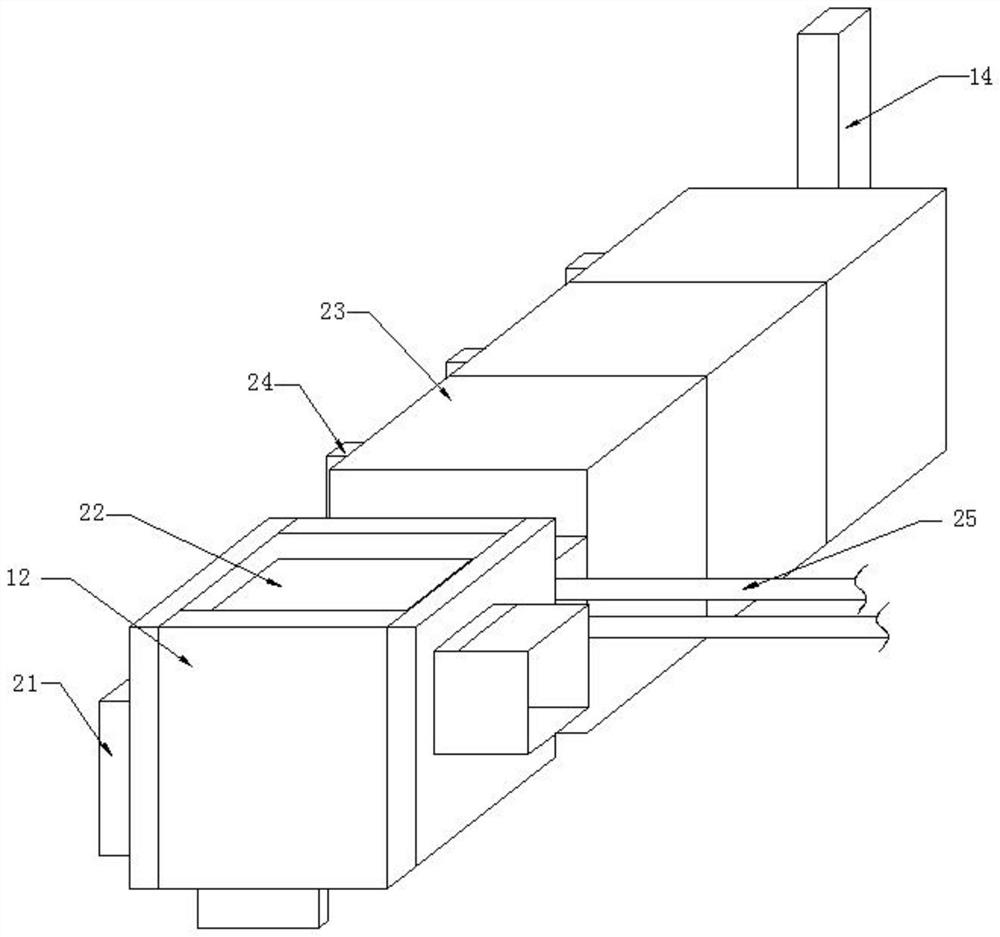

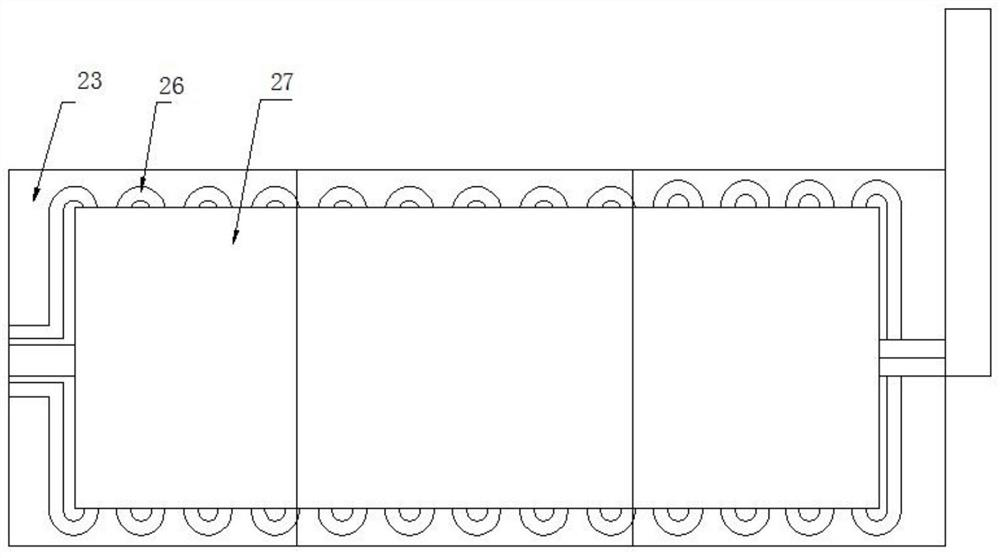

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: an energy-saving and environmentally friendly combustion furnace with waste heat recovery and utilization, including a housing frame 1, a discharge port 2, a material pipe 3, a connecting shaft 4, a guide pipe 5, a top block 6, and an electric push rod 7 , pipe body 8, feeding pipe 9, auxiliary frame 10, adjustment assembly 11, fastening cover 111, first hydraulic air rod 112, auxiliary plate 113, external frame 12, fence 13, chimney pipe 14, filter frame 15, Bag dust collector 16, bottom cavity 17, storage frame 18, inner cavity 19, fan 20, rear cavity 21, combustion cavity 22, external cavity 23, thermometer 24, introduction pipe 25, connecting pipe 26, first internal Cavity 27, second internal cavity 28, third internal cavity 29, faucet 30, partition 31, valve 32, heating plate 33, auxiliary component 34, second hydraulic air rod 341, adapter plate 342, baffle 343 , water pump 35, observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com