Film bulk acoustic resonator for suppressing side energy radiation based on photonic crystal

A thin-film bulk acoustic wave and phononic crystal technology, applied in electrical components, impedance networks, etc., can solve problems such as quality factor reduction and resonator energy loss, and achieve the effect of improving quality factor and solving side energy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

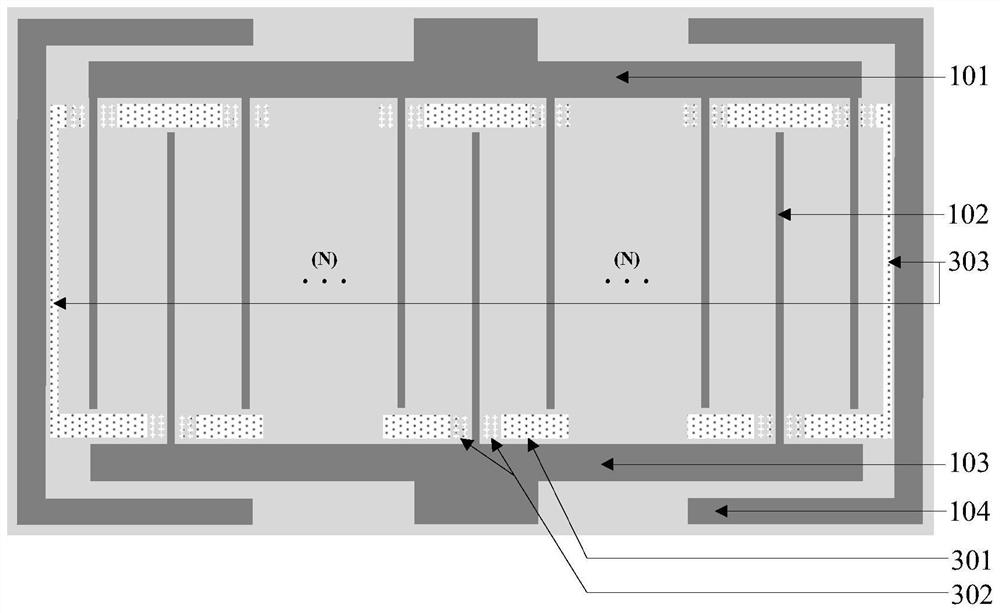

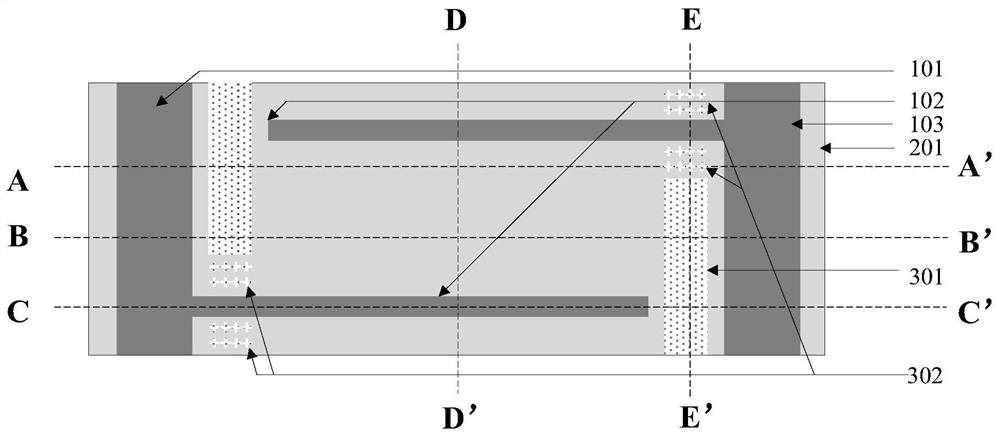

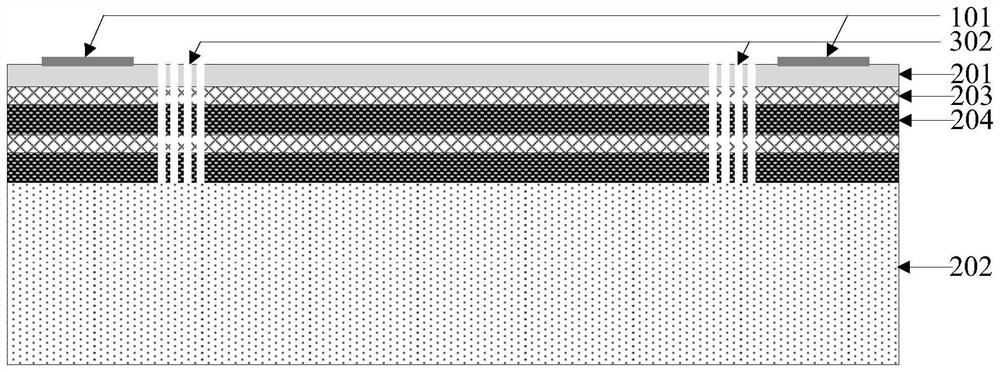

[0048] This embodiment provides a transversely excited thin-film bulk acoustic resonator. On the basis of the SMR Bragg reflection structure, a phononic crystal is used as a side energy radiation suppression structure to obtain a high-quality factor resonator with an operating frequency of 3.6GHz to 4.4GHz. ; Specific structure such as Figure 1 to Figure 7 As shown, it includes: a substrate 202, a high acoustic impedance film 204, a low acoustic impedance film 203, and a piezoelectric film 201 stacked sequentially on the substrate, an interdigital transducer set on the piezoelectric film, and a grounding protection electrode 104;

[0049] The interdigital transducer is located at the center of the upper surface of the piezoelectric film 201, and is composed of input electrodes 101 and output electrodes 103 intersected to form, and is used to realize the electrical signal input and output during the electromechanical conversion process of the piezoelectric film 201, and the inp...

Embodiment 2

[0056] This embodiment provides a transversely excited thin-film bulk acoustic resonator. On the basis of the SMR Bragg reflection structure, a phononic crystal is used as a side energy radiation suppression structure to obtain a high-quality factor resonator with an operating frequency of 3.6GHz to 4.4GHz. ; Specific structure such as Figure 12 to Figure 14 Shown, its only difference with embodiment 1 is:

[0057] The phononic crystal is composed of several unit structures arranged in an array, and the unit structures are as follows Figure 15 As shown, specifically, it is a circular metal pillar arranged on the upper surface of the piezoelectric film 201. The material of the circular metal pillar is platinum, the array size is 10×3, the cell size is a2 equal to 0.3um, d equal to 0.25um, and hPt is 0.23um and hLN are equal to 502nm; the bandgap diagram of this phononic crystal is as Figure 16 As shown, it can be seen from the figure that the phononic crystal has a local b...

Embodiment 3

[0060] This embodiment provides a transversely excited film bulk acoustic resonator. On the basis of the Freestanding structure, a phononic crystal is used as a side energy radiation suppression structure to obtain a high quality factor resonator. Its structure is as follows Figure 19 As shown, it specifically includes: a substrate 202, a piezoelectric film 201 provided on the substrate, an interdigital transducer provided on the piezoelectric film, and a grounding guard electrode 104;

[0061] A back cavity is provided at the bottom of the substrate 202, located directly below the IDT;

[0062] The interdigital transducer is located at the center of the upper surface of the piezoelectric film 201, and is composed of input electrodes 101 and output electrodes 103 intersected to form, and is used to realize the electrical signal input and output during the electromechanical conversion process of the piezoelectric film 201, and the input electrodes 101 can convert electrical en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com