Self-repairing bulletproof composite board and manufacturing method thereof

A composite plate and self-repairing material technology, applied in chemical instruments and methods, protective clothing, protective equipment, etc., can solve the problem of bulletproof equipment losing protective performance and achieve good bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

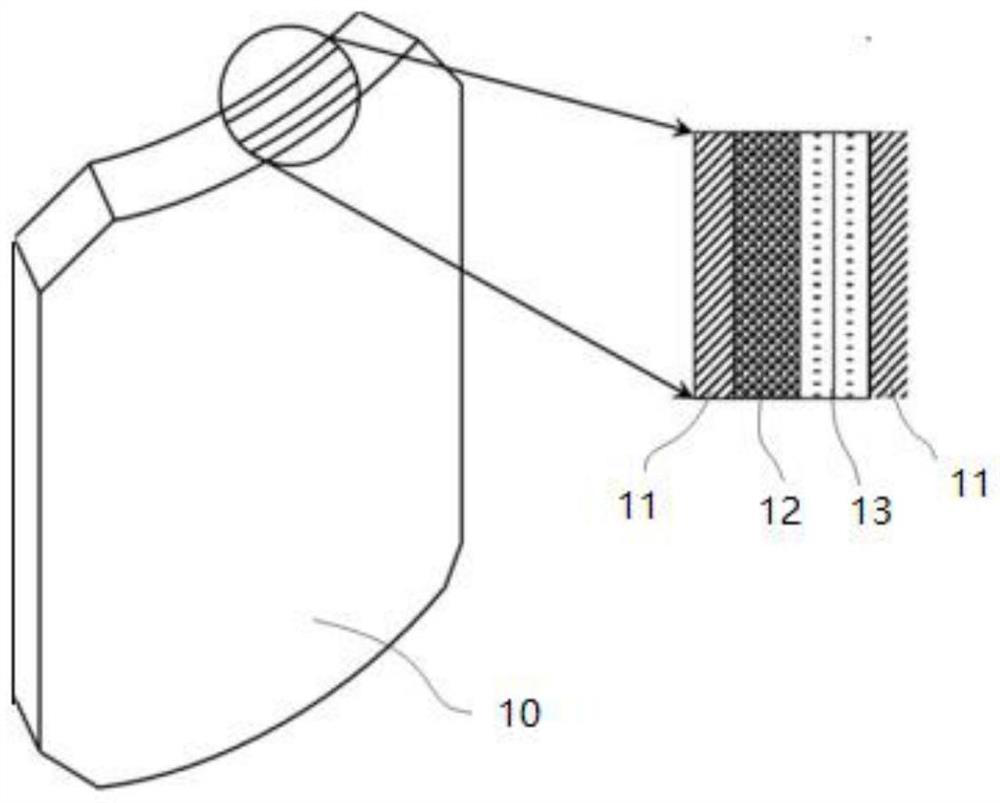

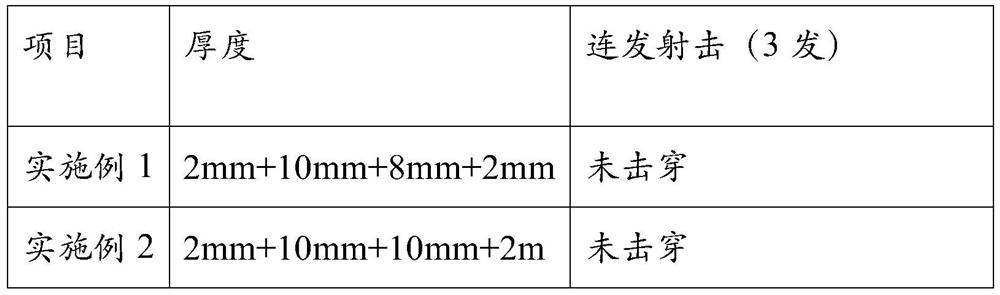

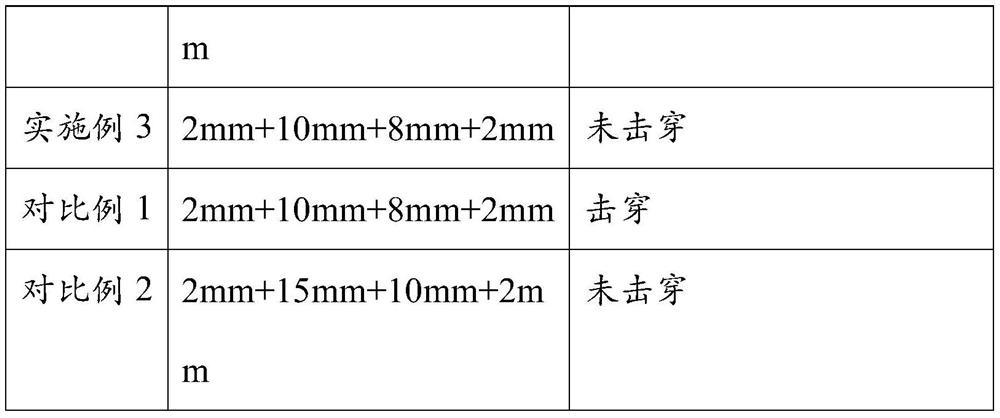

[0042] like figure 1 Shown: a self-healing bulletproof composite sheet, its structure is cladding layer + self-healing bulletproof layer + bulletproof back layer + cladding layer (thickness is 2mm+10mm+8mm+2mm);

[0043] The self-healing bulletproof layer includes a shell, and the shell is filled with a self-healing material, and the self-healing material is composed of ceramic balls and shear thickening liquid.

[0044] Wherein, the ceramic balls are composed of alumina and silicon carbide in a mass ratio of 1:1, and the particle size of the ceramic balls is 0.2-20 mm; the shear thickening liquid includes organic solvents and inorganic particles, and the shear thickening liquid The weight fraction of the organic solvent in the thick liquid is 70%, the organic solvent is glycerol, the inorganic particles are silicon dioxide and titanium dioxide (mass ratio is 1:1), and the particle size is 80-120nm.

[0045] The preparation method of described shear thickening liquid is as fo...

Embodiment 2

[0060] A self-healing bullet-proof composite sheet, the structure of which is a cladding layer + a self-healing bullet-proof layer + a bullet-proof back layer + a cladding layer (thickness is 2mm+10mm+8mm+2mm);

[0061] The self-healing bulletproof layer includes a shell, and the shell is filled with a self-healing material, and the self-healing material is composed of ceramic balls and shear thickening liquid.

[0062] Wherein, the ceramic balls are composed of titanium nitride and aluminum nitride in a mass ratio of 1:2, and the particle size of the ceramic balls is 0.2-20 mm; the shear thickening liquid includes organic solvents and inorganic particles, and the shear thickening liquid includes organic solvents and inorganic particles. The weight fraction of the organic solvent in the thickening liquid is 80%, the organic solvent is polyethylene glycol (molecular weight is 1000-1500 g / mol), the inorganic particles are silicon dioxide, and the particle size is 80-120 nm.

[0...

Embodiment 3

[0078] A self-healing bullet-proof composite sheet, the structural form of which is a coating layer + a self-healing bullet-proof layer + a bullet-proof back layer + a coating layer (thickness is 2mm+10mm+10mm+2mm);

[0079] The self-healing bulletproof layer includes a shell, and the shell is filled with a self-healing material, and the self-healing material is composed of ceramic balls and shear thickening liquid.

[0080] Among them, the ceramic balls are composed of boron carbide, silicon nitride, zirconia, and quartz in a mass ratio of 1:1:1:1, and the particle size of the ceramic balls is 0.2-20 mm; the shear thickening liquid includes an organic solvent , inorganic particles and surface treatment agent, the weight fraction of the organic solvent in the shear thickening liquid is 90%, the organic solvent is polypropylene glycol (molecular weight is 1000-1500g / mol), and the inorganic particles are titanium dioxide and Alumina trioxide (mass ratio is 1:2, particle size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com